Fiberglass fabric stands as one of the most versatile and essential materials in modern industrial applications, serving critical roles across marine, construction, and automotive sectors. This advanced textile combines glass fibers woven into various patterns to create a material that offers exceptional strength-to-weight ratios, corrosion resistance, and thermal stability. Industries worldwide rely on fiberglass fabric for its unique properties that make it indispensable for demanding applications where traditional materials fall short.

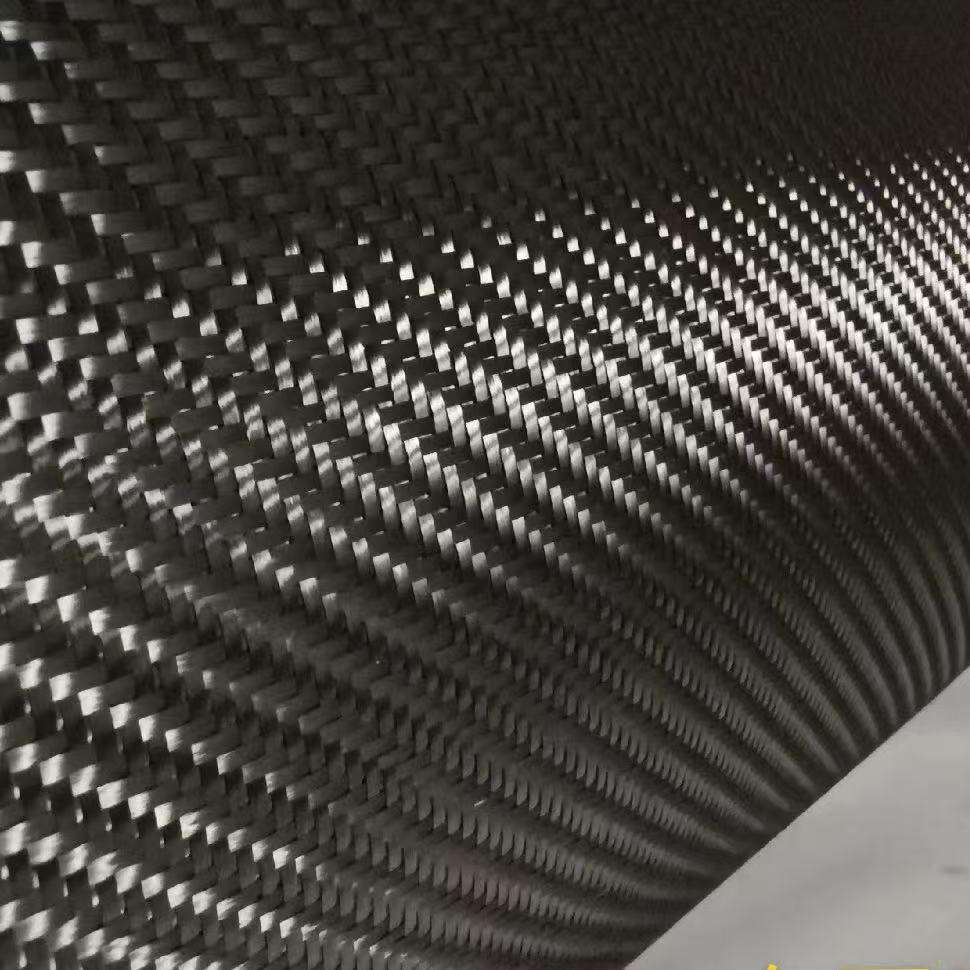

The manufacturing process of fiberglass fabric involves melting silica sand and other raw materials at extremely high temperatures to form continuous glass filaments. These filaments are then woven into various patterns including plain weave, twill weave, and satin weave configurations. The resulting fabric maintains the inherent properties of glass while offering textile-like flexibility and workability. Modern production techniques ensure consistent quality and precise specifications that meet stringent industry standards.

Understanding the fundamental characteristics of fiberglass fabric reveals why it has become so crucial across multiple industries. The material exhibits remarkable tensile strength often exceeding that of steel on a weight-for-weight basis. Additionally, its non-combustible nature and resistance to chemical degradation make it suitable for environments where safety and longevity are paramount concerns.

Marine Applications and Benefits

Boat Hull Construction and Repair

Marine environments present unique challenges that demand materials capable of withstanding constant moisture exposure, salt corrosion, and mechanical stress. Fiberglass fabric serves as the backbone of modern boat construction, providing the structural integrity needed for hulls that must endure harsh oceanic conditions. The material's resistance to water absorption prevents delamination and structural degradation that commonly affects other materials in marine applications.

Boat manufacturers utilize different weave patterns of fiberglass fabric depending on specific hull requirements. Biaxial fabrics provide excellent directional strength for areas experiencing high stress loads, while triaxial weaves offer multidirectional reinforcement for complex curved surfaces. The repair and maintenance sector also heavily depends on fiberglass fabric patches and overlays to restore damaged hulls to their original strength specifications.

Marine Infrastructure and Equipment

Beyond vessel construction, fiberglass fabric plays a crucial role in marine infrastructure development. Dock structures, pier reinforcements, and offshore platform components utilize this material for its ability to resist saltwater corrosion while maintaining structural stability. The fabric's lightweight nature reduces overall structural loads while providing necessary strength characteristics.

Marine equipment manufacturers incorporate fiberglass fabric into safety equipment, storage tanks, and piping systems. The material's chemical inertness makes it ideal for storing various marine fuels and chemicals without degradation concerns. Additionally, its electrical insulation properties provide safety benefits in marine electrical applications where moisture presents constant hazards.

Construction Industry Applications

Structural Reinforcement Solutions

Construction projects increasingly rely on fiberglass fabric for structural reinforcement applications where traditional steel reinforcement may be impractical or insufficient. The material's corrosion resistance makes it particularly valuable in environments exposed to de-icing salts, chemical exposure, or high humidity conditions. Bridge deck overlays, tunnel linings, and parking garage repairs commonly utilize fiberglass fabric systems for long-term durability solutions.

The construction industry appreciates fiberglass fabric's ability to conform to irregular surfaces while providing consistent reinforcement strength. Unlike rigid materials, the fabric can accommodate building movement and settling without compromising structural integrity. This flexibility proves essential in seismic regions where buildings must withstand dynamic loading conditions.

Architectural and Decorative Applications

Modern architecture incorporates fiberglass fabric into both functional and aesthetic applications. Tensioned fabric structures utilize the material's strength and weather resistance to create large-span roofing systems with minimal support requirements. The fabric's translucent properties allow natural light penetration while providing weather protection, making it ideal for atriums, stadiums, and exhibition halls.

Decorative concrete applications benefit from fiberglass fabric reinforcement that prevents cracking and extends service life. Architectural precast panels, decorative facades, and sculptural elements utilize the material to achieve complex geometries while maintaining structural requirements. The fabric's ability to take detailed impressions allows for intricate surface textures and patterns in finished concrete products.

Automotive Industry Integration

Lightweight Vehicle Components

The automotive industry's push toward fuel efficiency and emission reduction has increased demand for lightweight materials that maintain safety and performance standards. Fiberglass fabric enables manufacturers to create vehicle components that significantly reduce weight compared to traditional steel alternatives. Body panels, interior components, and structural elements benefit from the material's high strength-to-weight ratio.

Advanced composite manufacturing techniques utilize fiberglass fabric in conjunction with various resin systems to create components with precisely tailored properties. Automotive engineers can optimize fiber orientation and fabric architecture to match specific loading conditions in different vehicle areas. This level of customization allows for weight reduction without compromising crash safety or durability requirements.

Performance and Racing Applications

High-performance automotive applications demand materials that can withstand extreme conditions while providing maximum strength and minimum weight. Racing vehicles extensively use fiberglass fabric in body panels, aerodynamic components, and safety equipment manufacturing. The material's ability to absorb impact energy makes it valuable for crash protection systems in motorsports applications.

Aftermarket automotive components frequently incorporate fiberglass fabric for performance enhancements and aesthetic modifications. Hood scoops, spoilers, and body kits utilize the material's moldability and finish characteristics to achieve desired appearance and functional requirements. The automotive restoration industry also relies on fiberglass fabric for reproducing discontinued body parts and panels.

Technical Properties and Performance Characteristics

Mechanical Strength and Durability

The exceptional mechanical properties of fiberglass fabric result from its glass fiber composition and weave structure. Tensile strength values typically range from 200,000 to 500,000 PSI depending on fiber type and fabric construction. This strength remains consistent across a wide temperature range, making the material suitable for applications experiencing thermal cycling.

Fatigue resistance represents another critical performance characteristic that makes fiberglass fabric suitable for dynamic loading applications. Unlike metals that can fail suddenly after reaching fatigue limits, fiberglass fabric typically exhibits gradual degradation that provides warning signs before failure. This characteristic enhances safety in critical applications across all three industries.

Environmental Resistance and Longevity

Chemical resistance properties of fiberglass fabric make it suitable for harsh environmental conditions encountered in marine, construction, and automotive applications. The material resists degradation from acids, alkalis, and organic solvents that would quickly damage other reinforcement materials. UV resistance treatments can be applied to extend outdoor service life in direct sunlight exposure.

Thermal stability characteristics allow fiberglass fabric to maintain its properties across temperature ranges from cryogenic conditions to several hundred degrees Fahrenheit. This stability proves crucial in automotive engine compartments, marine exhaust systems, and construction applications involving thermal cycling. The material's low thermal expansion coefficient also contributes to dimensional stability in varying temperature conditions.

Manufacturing and Processing Considerations

Fabric Selection and Specification

Selecting appropriate fiberglass fabric specifications requires understanding the relationship between weave pattern, fiber type, and intended application requirements. Plain weave fabrics offer balanced properties in both warp and fill directions, making them suitable for general-purpose applications. Twill weaves provide better drapability for complex curved surfaces while maintaining good mechanical properties.

Weight specifications typically range from light fabrics under 4 ounces per square yard for finish applications to heavy fabrics exceeding 24 ounces per square yard for structural applications. Thread count and fiber diameter affect both handling characteristics and final composite properties. Higher thread counts generally provide smoother surface finishes but may reduce resin penetration in thick laminates.

Processing Techniques and Quality Control

Proper handling and processing techniques ensure optimal performance from fiberglass fabric applications. Storage conditions must protect the fabric from moisture absorption and contamination that could affect resin bonding. Cutting and preparation methods should minimize fiber damage and fraying that could create stress concentration points in finished laminates.

Quality control procedures during manufacturing involve regular testing of fabric properties including tensile strength, weight per unit area, and resin compatibility. Batch tracking systems ensure traceability for critical applications where material certification is required. Post-cure inspection techniques can identify potential defects before components enter service in marine, construction, or automotive applications.

FAQ

What makes fiberglass fabric superior to other reinforcement materials

Fiberglass fabric offers an exceptional combination of high tensile strength, corrosion resistance, and lightweight properties that surpass most alternative reinforcement materials. Unlike steel reinforcement that can rust and expand, causing concrete cracking, fiberglass fabric maintains its integrity in harsh environments. Its strength-to-weight ratio often exceeds steel while providing electrical insulation and chemical resistance properties that metals cannot match.

How does fiberglass fabric perform in extreme temperature conditions

Fiberglass fabric maintains its mechanical properties across a wide temperature range, typically from -50°F to 800°F depending on the specific glass type and resin system used. The material exhibits minimal thermal expansion and contraction, which prevents stress cracking in composite structures. In automotive applications, this thermal stability proves crucial for components near engines or exhaust systems where temperature fluctuations are common.

What factors determine the appropriate fiberglass fabric weight for specific applications

Fabric weight selection depends on structural requirements, thickness constraints, and processing considerations. Heavier fabrics provide greater reinforcement per layer but may be difficult to conform to complex shapes. Lighter fabrics offer better drapability and surface finish but require multiple layers for structural applications. Marine hulls typically use 18-24 oz fabrics for structural areas, while automotive body panels may use 6-10 oz fabrics for optimal weight savings.

How long can fiberglass fabric components last in service

Properly manufactured and maintained fiberglass fabric components can provide service lives of 20-30 years or more in typical applications. Marine vessels often exceed 25-year lifespans with proper maintenance, while construction applications may last 50 years or longer. The material's resistance to corrosion, fatigue, and environmental degradation contributes to its longevity. Regular inspection and maintenance protocols can extend service life even further by addressing minor issues before they compromise structural integrity.