Industrial applications demand materials that can withstand extreme conditions while maintaining structural integrity and performance reliability. Fiberglass fabric has emerged as a critical component across numerous sectors, from aerospace manufacturing to marine construction, due to its exceptional strength-to-weight ratio and thermal resistance properties. When selecting fiberglass fabric for industrial use, understanding quality standards becomes paramount to ensuring project success and long-term durability. The complexity of modern industrial requirements necessitates a comprehensive approach to material selection that considers multiple factors including weave patterns, glass fiber composition, and compliance with international standards.

Understanding Industrial Quality Standards for Fiberglass Materials

International Certification Requirements

Industrial grade fiberglass fabric must meet stringent international standards that govern material composition, performance characteristics, and manufacturing processes. Organizations such as ASTM International, ISO, and various industry-specific bodies establish these benchmarks to ensure consistent quality across global supply chains. These certifications address critical aspects including tensile strength, thermal stability, chemical resistance, and dimensional accuracy that directly impact the fabric's performance in demanding industrial environments.

Compliance with standards like ASTM D579 for glass fiber specifications and ISO 2078 for textile glass products provides assurance that the material will perform predictably under specified conditions. Manufacturing facilities must maintain rigorous quality control systems that include regular testing protocols, batch tracking, and documentation procedures. This systematic approach ensures that each roll of fiberglass fabric delivers consistent properties that meet or exceed established performance thresholds.

Performance Metrics and Testing Protocols

Critical performance metrics for industrial fiberglass fabric include tensile strength measurements, elongation at break, and thermal degradation temperatures. These properties are evaluated through standardized testing methods that simulate real-world operating conditions. Tensile testing determines the maximum stress the fabric can withstand before failure, while thermal analysis reveals the material's behavior across temperature ranges typical in industrial applications.

Additional testing encompasses chemical resistance evaluations, where fabric samples are exposed to various industrial chemicals and solvents to assess degradation over time. Dimensional stability testing measures how the fabric responds to temperature cycling and moisture exposure, ensuring it maintains its structural properties throughout the service life. These comprehensive testing protocols provide quantitative data that enables engineers to make informed material selection decisions based on specific application requirements.

Glass Fiber Composition and Manufacturing Excellence

E-Glass Versus Specialty Glass Formulations

The foundation of high-quality fiberglass fabric begins with the glass fiber composition, where E-glass remains the most widely used formulation for general industrial applications. E-glass offers excellent electrical insulation properties, good mechanical strength, and cost-effectiveness that makes it suitable for a broad range of manufacturing processes. However, specialty applications may require advanced glass formulations such as S-glass for enhanced strength or C-glass for superior chemical resistance.

Understanding the relationship between glass composition and performance characteristics enables optimal material selection for specific industrial requirements. S-glass formulations provide approximately 40% higher tensile strength compared to E-glass, making them ideal for aerospace and high-performance automotive applications. Meanwhile, AR-glass compositions offer alkaline resistance properties essential for construction and infrastructure projects where exposure to concrete and masonry materials occurs.

Fiber Diameter and Surface Treatment Considerations

Fiber diameter significantly influences the mechanical properties and processing characteristics of fiberglass fabric. Smaller diameter fibers typically provide higher strength and better flexibility, while larger diameters offer improved abrasion resistance and ease of handling during manufacturing operations. Industrial applications often specify fiber diameters ranging from 5 to 25 micrometers, with each range optimized for particular performance requirements and processing methods.

Surface treatments applied to glass fibers play a crucial role in determining compatibility with resin systems and overall composite performance. Silane coupling agents create chemical bonds between the glass surface and polymer matrices, improving load transfer and moisture resistance. The selection of appropriate sizing formulations ensures optimal wetting characteristics and processing behavior during lamination or pultrusion operations.

Weave Patterns and Structural Configuration Options

Plain Weave Characteristics and Applications

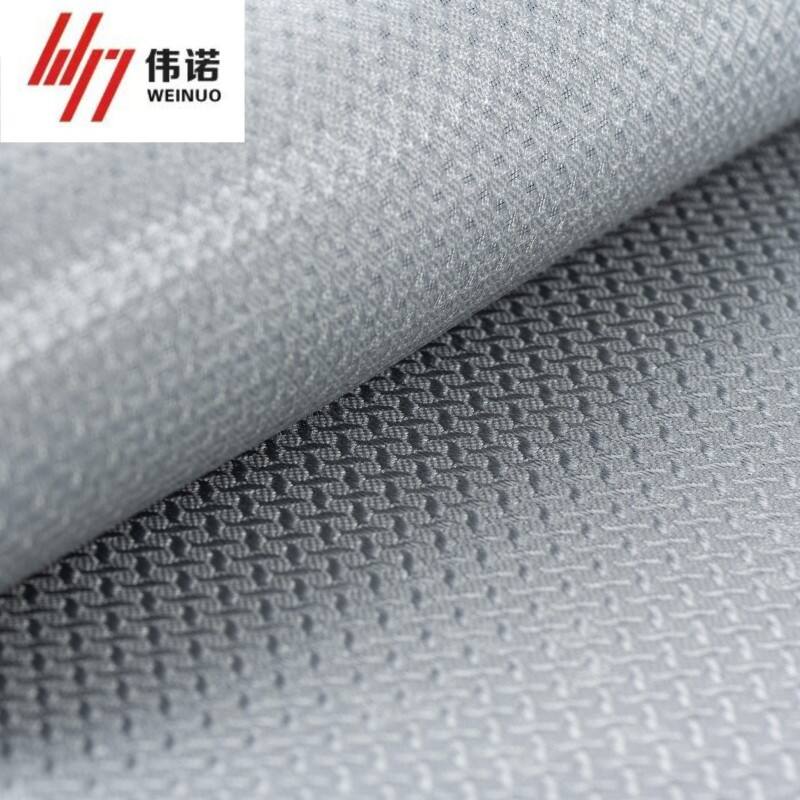

Plain weave represents the most fundamental weave pattern for fiberglass fabric, offering excellent dimensional stability and uniform strength distribution in both warp and fill directions. This configuration provides good drapability for complex geometries while maintaining consistent fiber architecture throughout the fabric structure. Industrial applications benefit from the predictable mechanical properties and ease of handling that plain weave fabrics deliver during manufacturing processes.

The tight interlacing pattern of plain weave creates a stable platform for resin impregnation while minimizing fiber movement during composite fabrication. This stability proves particularly valuable in hand lay-up operations and automated manufacturing processes where consistent fiber orientation is critical. The balanced construction ensures that mechanical loads are distributed evenly across the fabric structure, preventing localized stress concentrations that could compromise structural integrity.

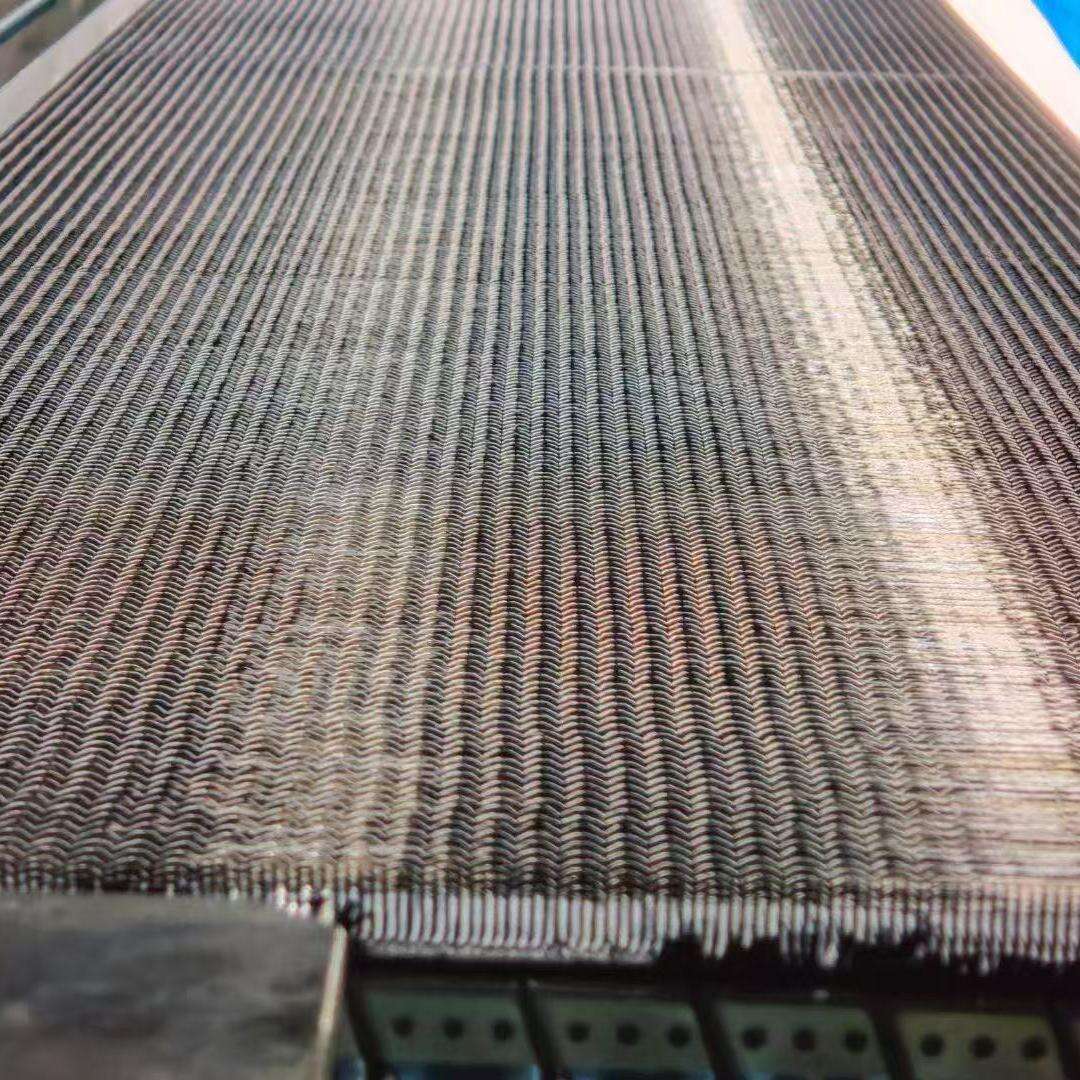

Twill and Specialty Weave Configurations

Twill weave patterns offer enhanced drapability and conformability compared to plain weave structures, making them ideal for complex three-dimensional shapes and curved surfaces. The diagonal interlacing pattern reduces crimp in the yarns, resulting in higher mechanical properties and improved resin flow during processing. Industrial applications requiring complex geometries often specify twill weaves for their superior forming characteristics and aesthetic appearance.

Advanced weave configurations such as satin weaves provide minimal crimp and maximum fiber straightness, delivering optimal mechanical properties for high-performance applications. These specialty patterns require careful consideration of manufacturing requirements and end-use conditions to ensure appropriate selection. The reduced interlacing points in satin weaves can improve fatigue resistance but may compromise dimensional stability compared to more tightly woven patterns.

Quality Control and Inspection Procedures

Incoming Material Verification Protocols

Establishing comprehensive quality control procedures begins with incoming material verification that confirms specifications and certifications for each shipment of fiberglass fabric. Visual inspection protocols identify surface defects, contamination, or packaging damage that could affect material performance. Dimensional measurements verify fabric width, thickness, and weight specifications against purchase order requirements and established tolerances.

Documentation review ensures that material certificates provide complete traceability information including manufacturing dates, lot numbers, and test results. Statistical sampling procedures determine the appropriate number of test specimens required to validate material properties across each shipment. This systematic approach prevents defective materials from entering production processes where they could compromise product quality or create costly rework situations.

Process Monitoring and Batch Tracking Systems

Continuous monitoring during manufacturing operations ensures that fiberglass fabric maintains consistent properties throughout processing and storage periods. Environmental controls maintain appropriate temperature and humidity conditions that prevent moisture absorption or thermal degradation. Handling procedures minimize mechanical damage and contamination that could affect surface quality or fiber integrity.

Batch tracking systems provide complete traceability from raw materials through finished products, enabling rapid identification and containment of quality issues. Digital documentation systems capture critical process parameters and inspection results that support continuous improvement initiatives. This comprehensive approach to quality management ensures that industrial quality standards are maintained throughout the entire supply chain.

Application-Specific Selection Criteria

Aerospace and Defense Requirements

Aerospace applications impose the most stringent requirements for fiberglass fabric selection, demanding materials that meet military specifications and aviation industry standards. These applications require extensive documentation including material data sheets, test certificates, and compliance statements that verify conformance to applicable regulations. The critical nature of aerospace components necessitates materials with proven performance histories and established reliability records.

Temperature resistance becomes paramount in aerospace applications where materials must maintain structural integrity across extreme temperature ranges. Flame resistance properties ensure compliance with aviation safety regulations while low smoke generation characteristics protect personnel during emergency situations. The combination of high strength-to-weight ratios and excellent fatigue resistance makes specialty fiberglass fabrics essential components in modern aircraft structures.

Marine and Offshore Applications

Marine environments present unique challenges that require fiberglass fabric with exceptional moisture resistance and chemical stability. Saltwater exposure, UV radiation, and temperature cycling create demanding conditions that test material durability over extended service periods. Selection criteria must consider long-term performance in corrosive environments where traditional materials would rapidly deteriorate.

Offshore applications often specify materials with enhanced impact resistance and damage tolerance to withstand harsh operating conditions. The ability to maintain structural properties after minor damage events prevents catastrophic failures and extends service life. Specialized surface treatments and resin compatibility ensure optimal performance in marine composite structures where reliability is critical for safety and operational efficiency.

Cost-Performance Optimization Strategies

Total Cost of Ownership Analysis

Effective material selection requires comprehensive analysis that considers total cost of ownership rather than initial purchase price alone. This approach evaluates factors including processing efficiency, waste generation, labor requirements, and long-term maintenance costs. High-quality fiberglass fabric may command premium pricing but often delivers superior value through improved processing characteristics and extended service life.

Manufacturing efficiency gains from using premium materials can offset higher initial costs through reduced processing time and lower reject rates. Consistent material properties enable optimized manufacturing parameters that improve throughput and quality. The reduced need for rework and warranty claims provides additional cost benefits that justify investment in superior materials.

Supplier Qualification and Partnership Development

Building strategic partnerships with qualified suppliers ensures consistent access to materials that meet industrial quality standards. Supplier evaluation processes assess manufacturing capabilities, quality systems, and technical support resources that contribute to successful project outcomes. Long-term relationships enable collaborative development of specialized materials tailored to specific application requirements.

Regular supplier audits verify continued compliance with quality standards and identify opportunities for continuous improvement. Technical collaboration enables development of innovative solutions that address evolving industry requirements. Strong supplier partnerships provide competitive advantages through access to advanced materials and manufacturing technologies.

FAQ

What are the key differences between industrial grade and standard fiberglass fabric?

Industrial grade fiberglass fabric features tighter manufacturing tolerances, enhanced quality control procedures, and compliance with specific industry standards that ensure consistent performance in demanding applications. These materials undergo more extensive testing and documentation compared to standard commercial grades, providing greater reliability and traceability for critical applications.

How do I determine the appropriate weave pattern for my specific application?

Weave pattern selection depends on factors including part geometry complexity, required mechanical properties, and manufacturing processes. Plain weave offers good all-around performance for flat or simple curved parts, while twill and satin weaves provide better drapability for complex shapes. Consulting with technical specialists helps identify optimal patterns based on specific application requirements.

What documentation should I expect when purchasing industrial quality fiberglass fabric?

Complete documentation packages should include material certificates showing test results for key properties, compliance statements verifying adherence to applicable standards, and traceability information including lot numbers and manufacturing dates. Quality suppliers provide comprehensive documentation that supports material qualification and regulatory compliance requirements.

How can I verify that fiberglass fabric meets specified quality standards?

Verification involves reviewing supplier certifications, conducting incoming inspection procedures, and performing periodic testing of critical properties. Working with accredited testing laboratories provides independent validation of material properties and compliance with specifications. Maintaining detailed records enables tracking of material performance over time and identification of any quality trends.

Table of Contents

- Understanding Industrial Quality Standards for Fiberglass Materials

- Glass Fiber Composition and Manufacturing Excellence

- Weave Patterns and Structural Configuration Options

- Quality Control and Inspection Procedures

- Application-Specific Selection Criteria

- Cost-Performance Optimization Strategies

-

FAQ

- What are the key differences between industrial grade and standard fiberglass fabric?

- How do I determine the appropriate weave pattern for my specific application?

- What documentation should I expect when purchasing industrial quality fiberglass fabric?

- How can I verify that fiberglass fabric meets specified quality standards?