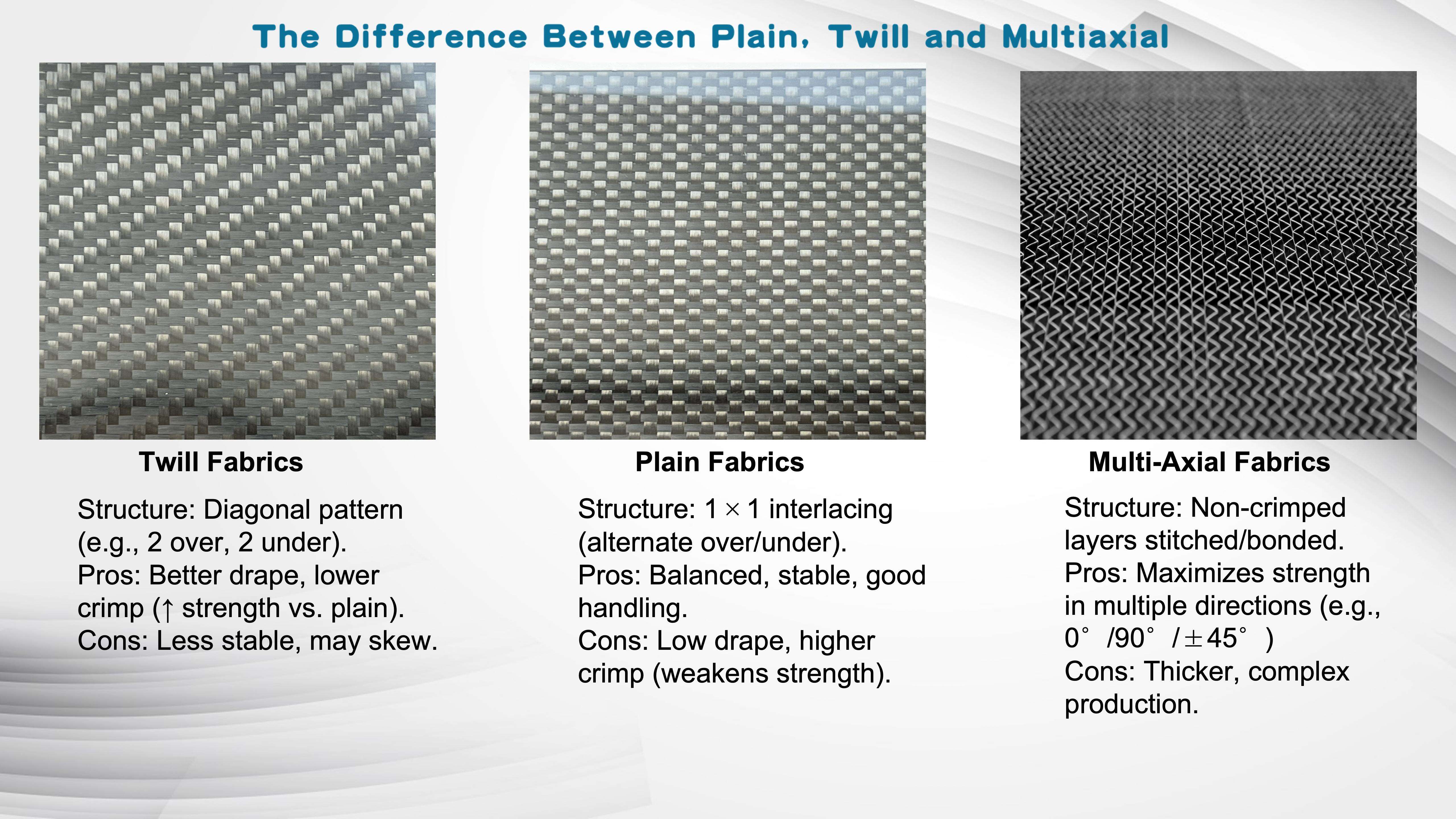

twill weave carbon fiber for industrial use

Twill weave carbon fiber represents a significant advancement in industrial materials, characterized by its distinctive diagonal pattern created through an over-under weaving technique. This specialized weaving method produces a fabric where the warp threads pass over two or more weft threads before going under, creating a pattern that enhances both aesthetic appeal and structural integrity. The material's unique construction offers superior draping capabilities, making it ideal for complex geometric shapes and curved surfaces in industrial applications. With a typical fiber content of 3K to 12K tow sizes, twill weave carbon fiber delivers exceptional strength-to-weight ratios while maintaining flexibility and conformability. Its balanced structure provides uniform strength in multiple directions, making it particularly valuable in aerospace, automotive, and high-performance industrial applications. The material exhibits outstanding fatigue resistance, thermal stability, and dimensional consistency under varying environmental conditions. Modern manufacturing processes enable the production of twill weave carbon fiber with precise fiber alignment and consistent quality, ensuring reliable performance in demanding industrial environments. The material's versatility allows for integration with various resin systems, enabling customization for specific application requirements while maintaining its core characteristics of high strength and lightweight construction.