prepreg carbon fiber sheet

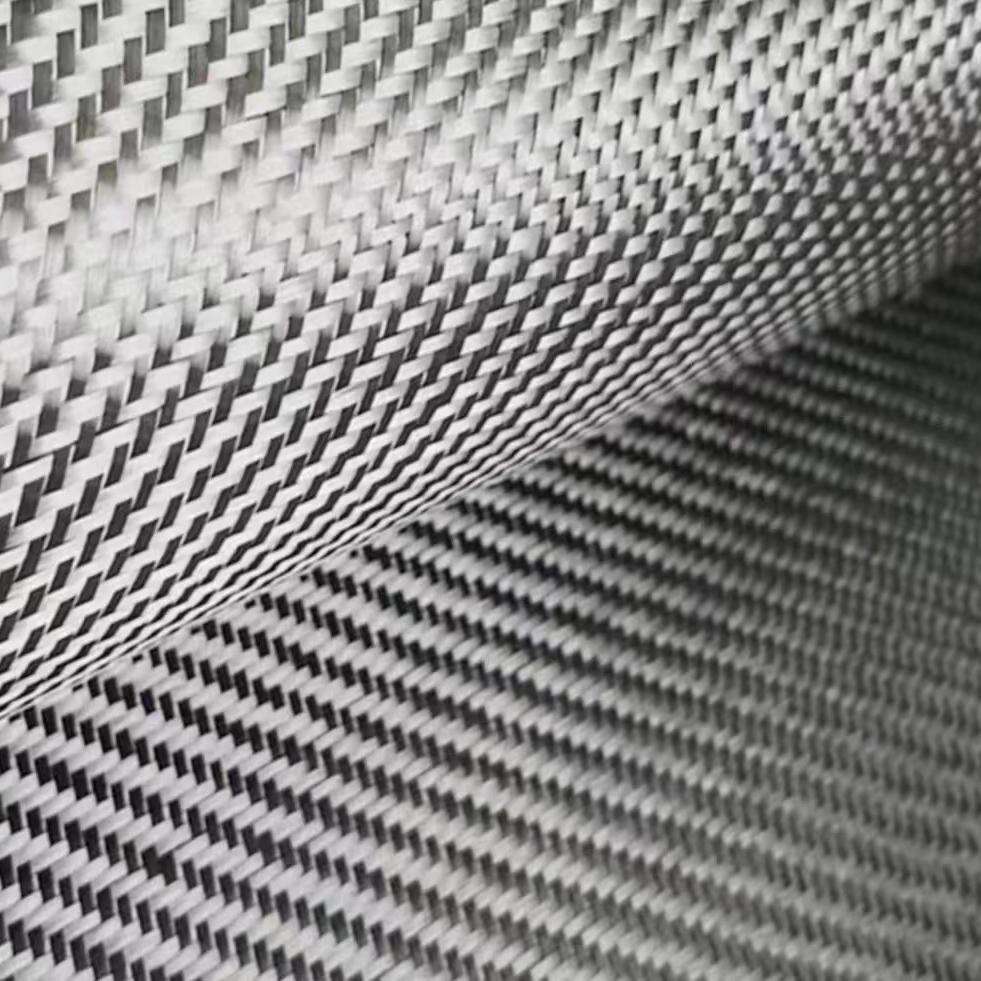

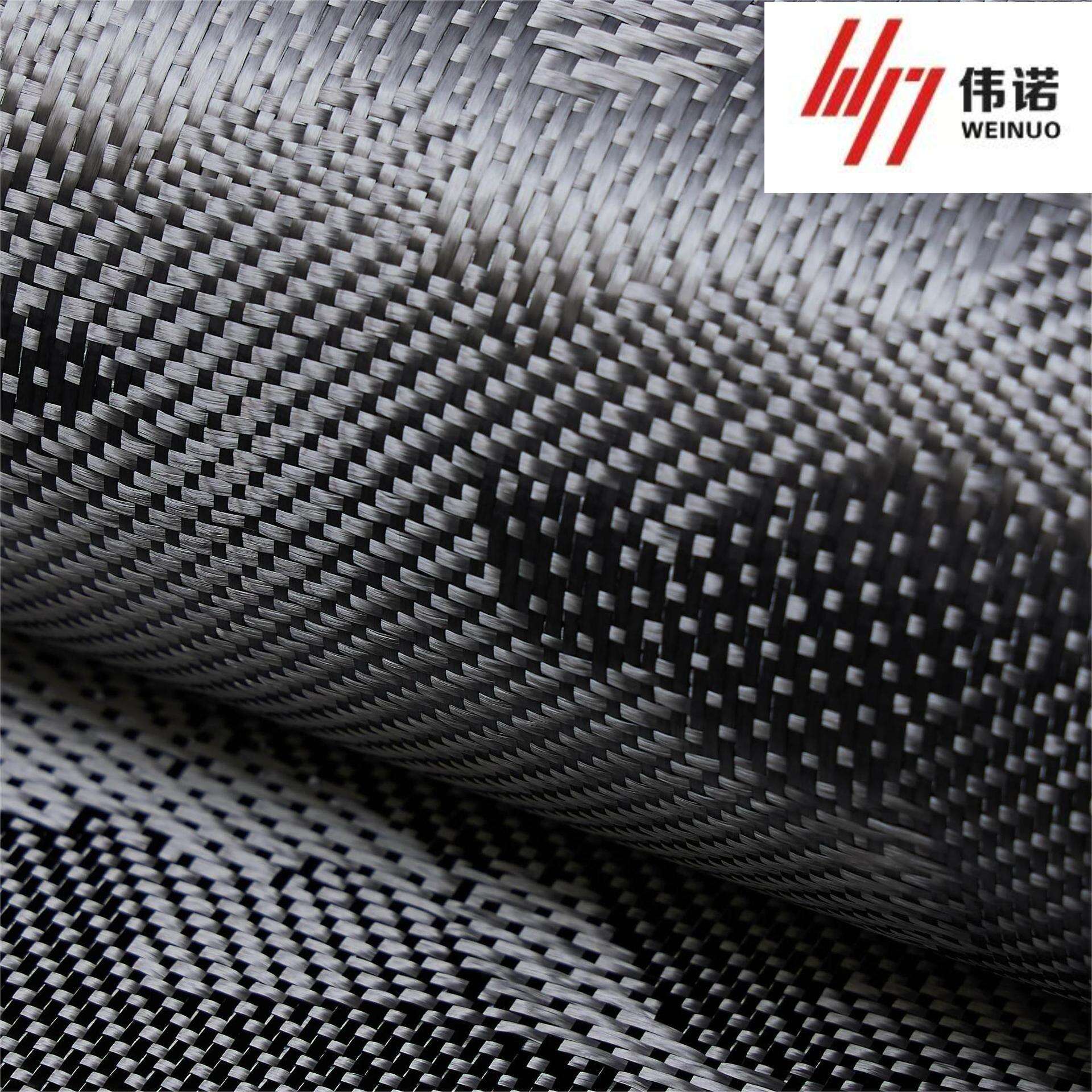

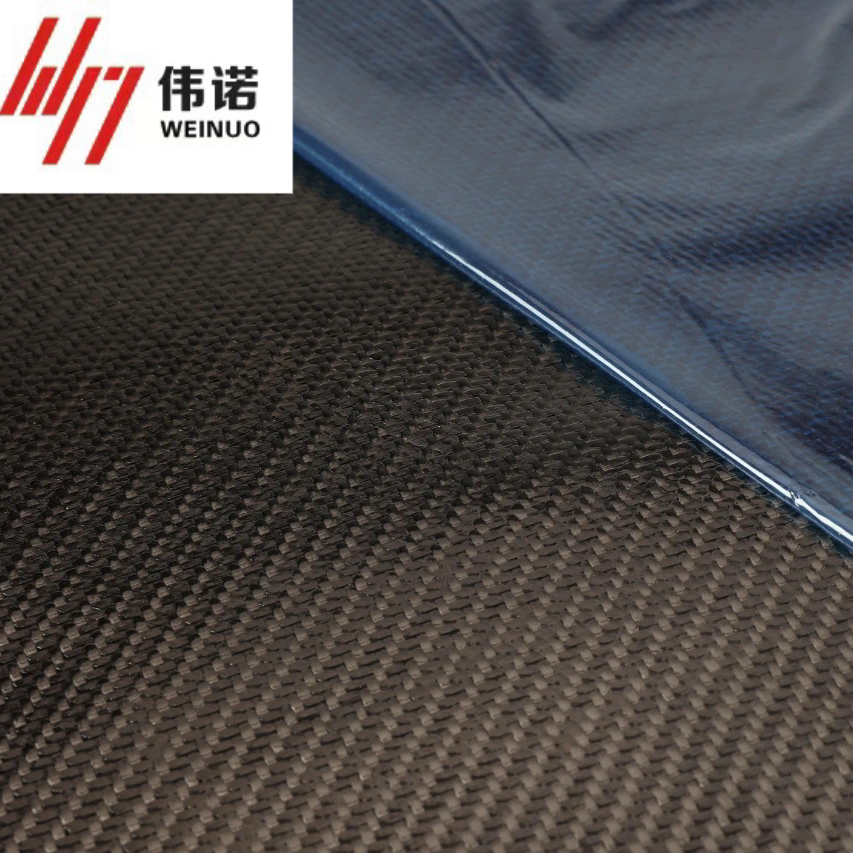

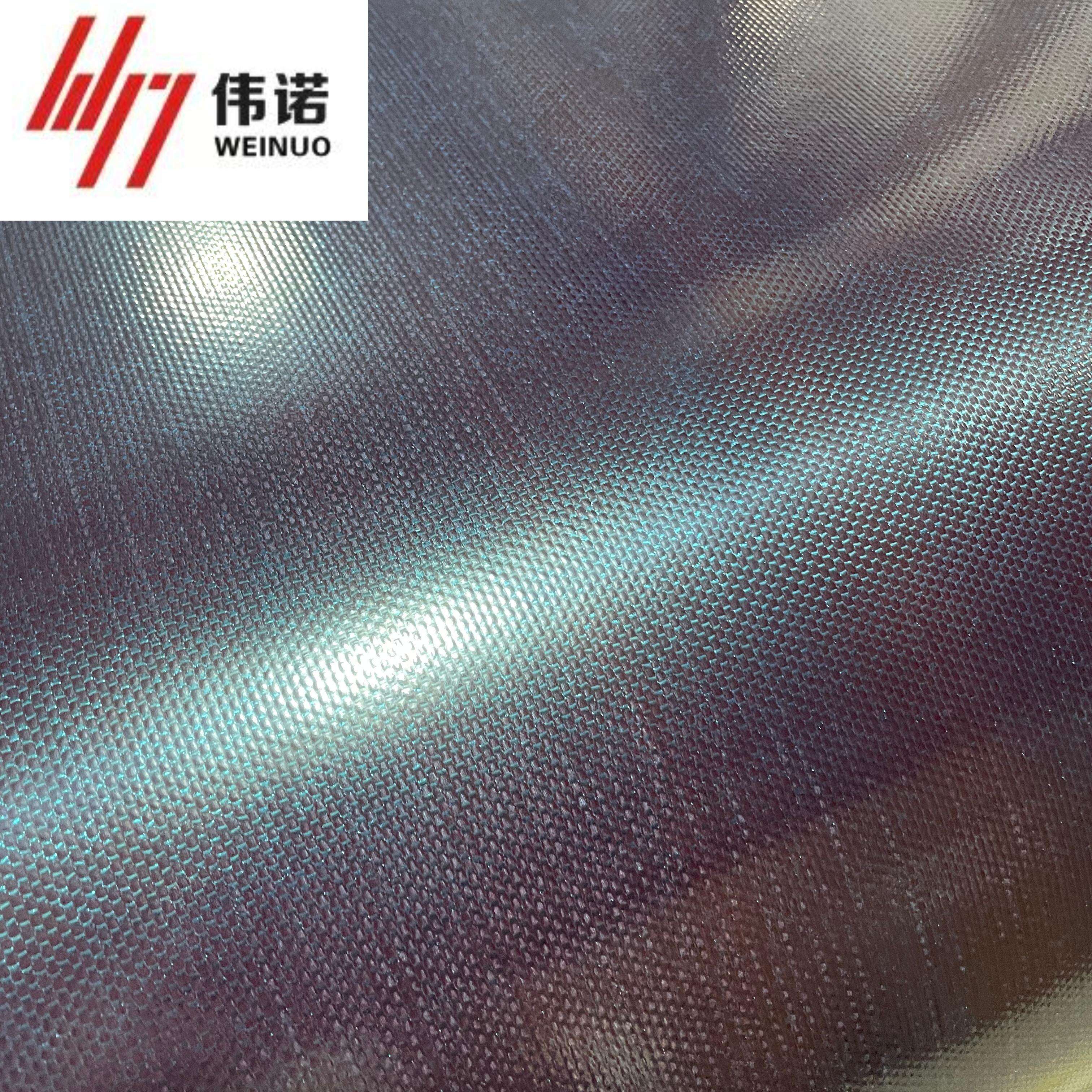

Prepreg carbon fiber sheets represent a cutting-edge advancement in composite materials technology, combining high-strength carbon fibers with pre-impregnated resin systems. These sophisticated materials are manufactured through a precise process where carbon fibers are carefully aligned and pre-impregnated with a thermosetting resin under controlled conditions. The resulting sheets offer an optimal fiber-to-resin ratio, ensuring consistent quality and performance across applications. These sheets are designed to cure under specific temperature and pressure conditions, creating exceptionally strong, lightweight structures. The pre-impregnated nature of these sheets eliminates the messy and time-consuming hand layup process traditionally associated with composite manufacturing. They provide superior strength-to-weight ratios, excellent fatigue resistance, and remarkable dimensional stability. Modern prepreg carbon fiber sheets also feature enhanced shelf life through specialized storage conditions, typically requiring refrigeration to maintain their properties until use. Their versatility allows for application in various industries, from aerospace and automotive to sporting goods and industrial equipment manufacturing. The sheets can be cut, shaped, and layered to create complex geometries while maintaining structural integrity and performance characteristics.