price of twill weave carbon fiber

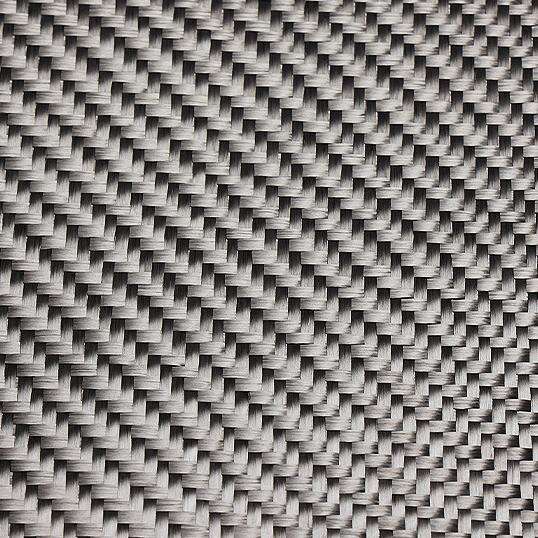

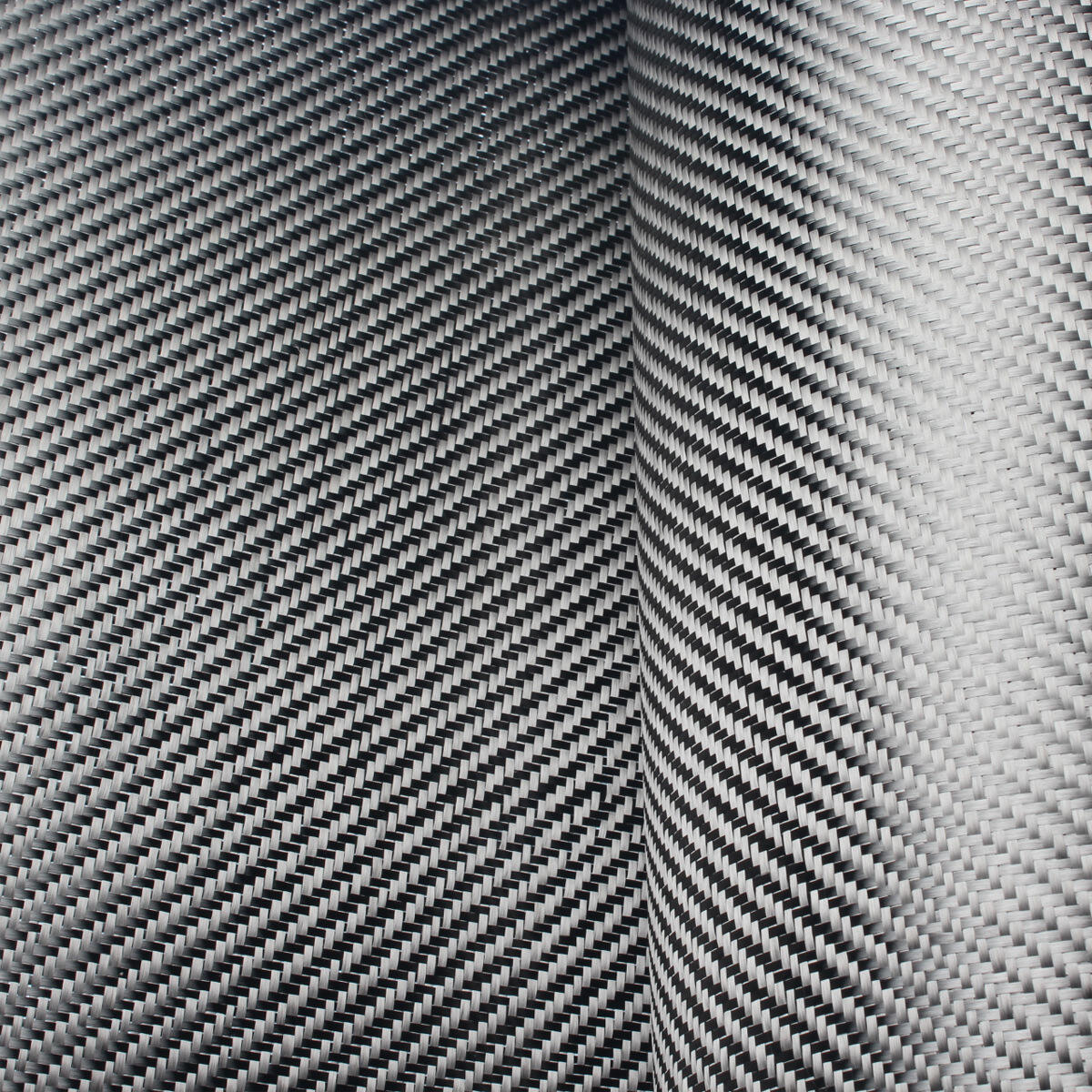

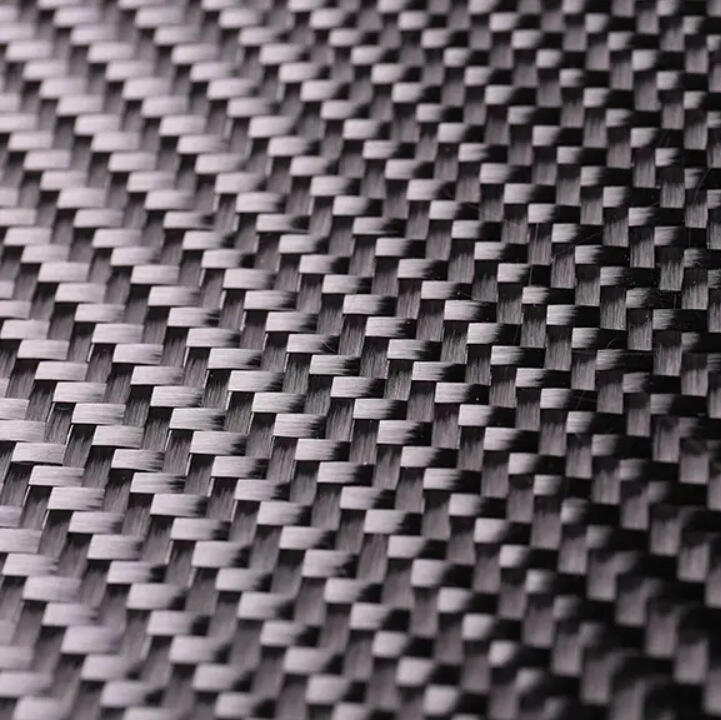

The price of twill weave carbon fiber represents a significant investment in advanced material technology. Typically ranging from $30 to $100 per square yard, this specialized material offers an exceptional balance of strength, aesthetics, and performance. Twill weave carbon fiber features a distinctive pattern where the carbon fiber tows are woven in an over-under pattern, creating a characteristic diagonal appearance. The price variations depend on several factors, including the grade of carbon fiber, weave density, and manufacturing quality. High-grade aerospace twill weave commands premium prices due to its stringent quality requirements and superior mechanical properties. Commercial-grade variants, while more affordable, still deliver impressive performance for automotive, sporting goods, and industrial applications. The material's cost reflects its complex manufacturing process, which involves precise weaving of carbon fiber tows and careful quality control measures. Despite the higher initial investment, the price of twill weave carbon fiber is often justified by its exceptional durability, weight savings, and aesthetic appeal, making it a preferred choice for high-performance applications where appearance and structural integrity are equally important.