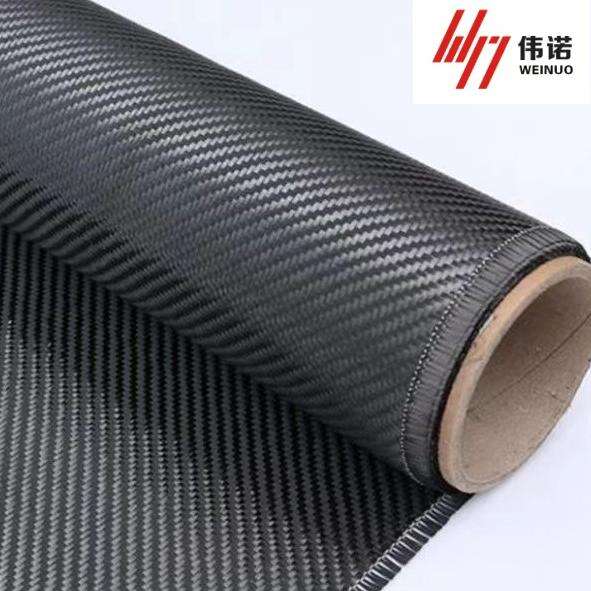

honeycomb carbon fiber cloth

Honeycomb carbon fiber cloth represents a revolutionary advancement in composite materials, combining the structural efficiency of honeycomb patterns with the exceptional properties of carbon fiber. This innovative material features a distinctive hexagonal cell structure that mimics nature's most efficient design, providing an optimal balance of strength and weight reduction. The manufacturing process involves precisely weaving carbon fiber threads into a honeycomb pattern, creating a material that exhibits remarkable structural integrity while maintaining minimal weight. The unique geometric arrangement allows for superior load distribution and enhanced mechanical properties in multiple directions. This advanced composite material offers exceptional resistance to compression, shear forces, and impact, making it ideal for applications requiring high performance and reliability. The honeycomb structure creates numerous void spaces within the material, significantly reducing overall weight while maintaining structural rigidity. Additionally, the material demonstrates excellent thermal stability, chemical resistance, and fatigue properties, ensuring long-term durability in demanding environments. The cloth's versatility allows it to be easily integrated into various manufacturing processes, including vacuum infusion, hand lay-up, and automated production methods.