Versatile Application Potential

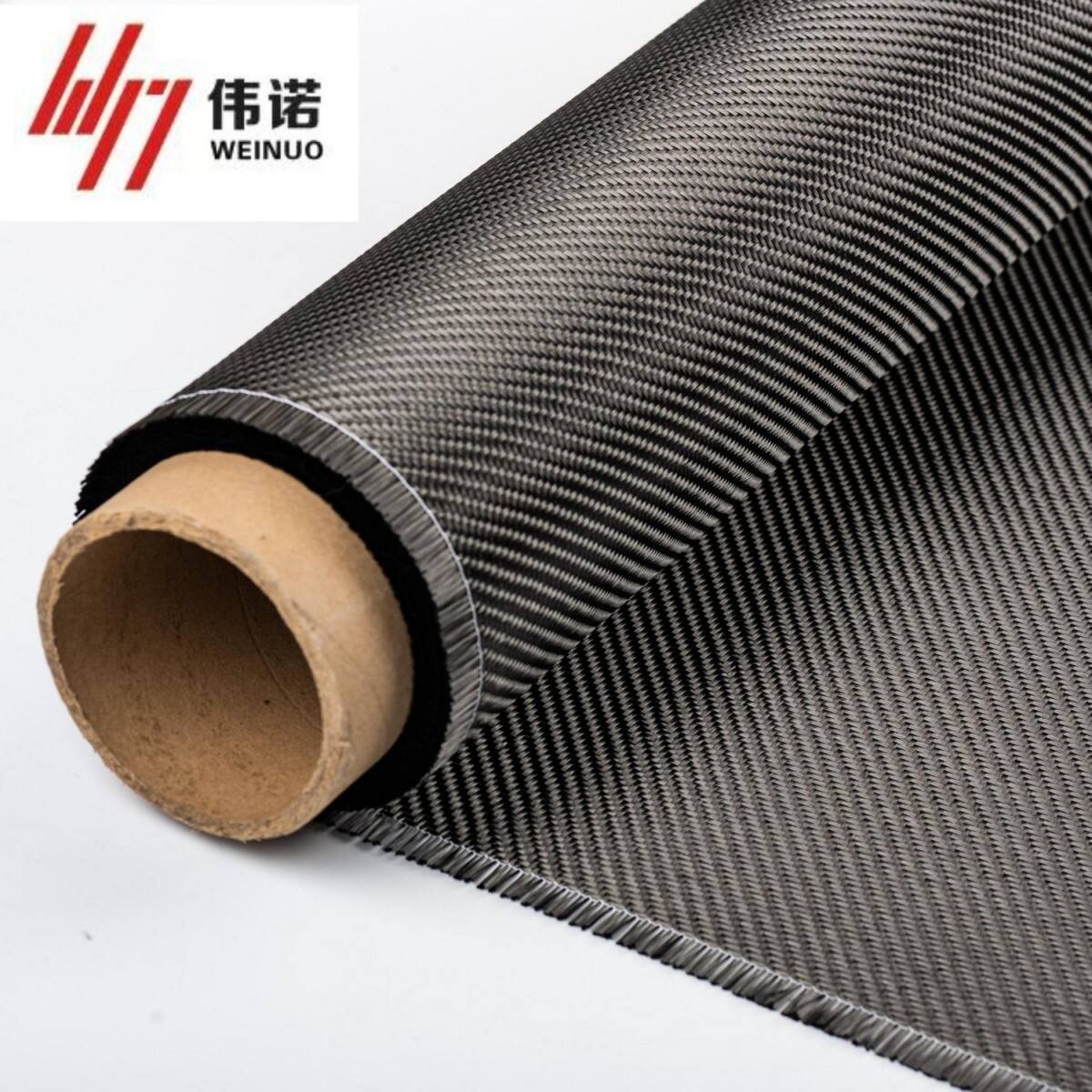

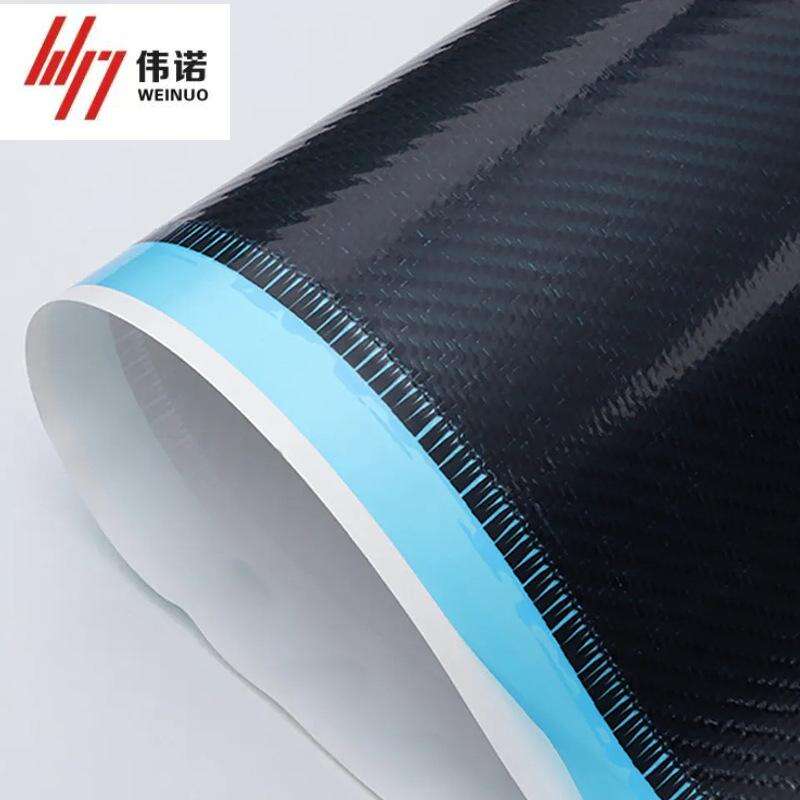

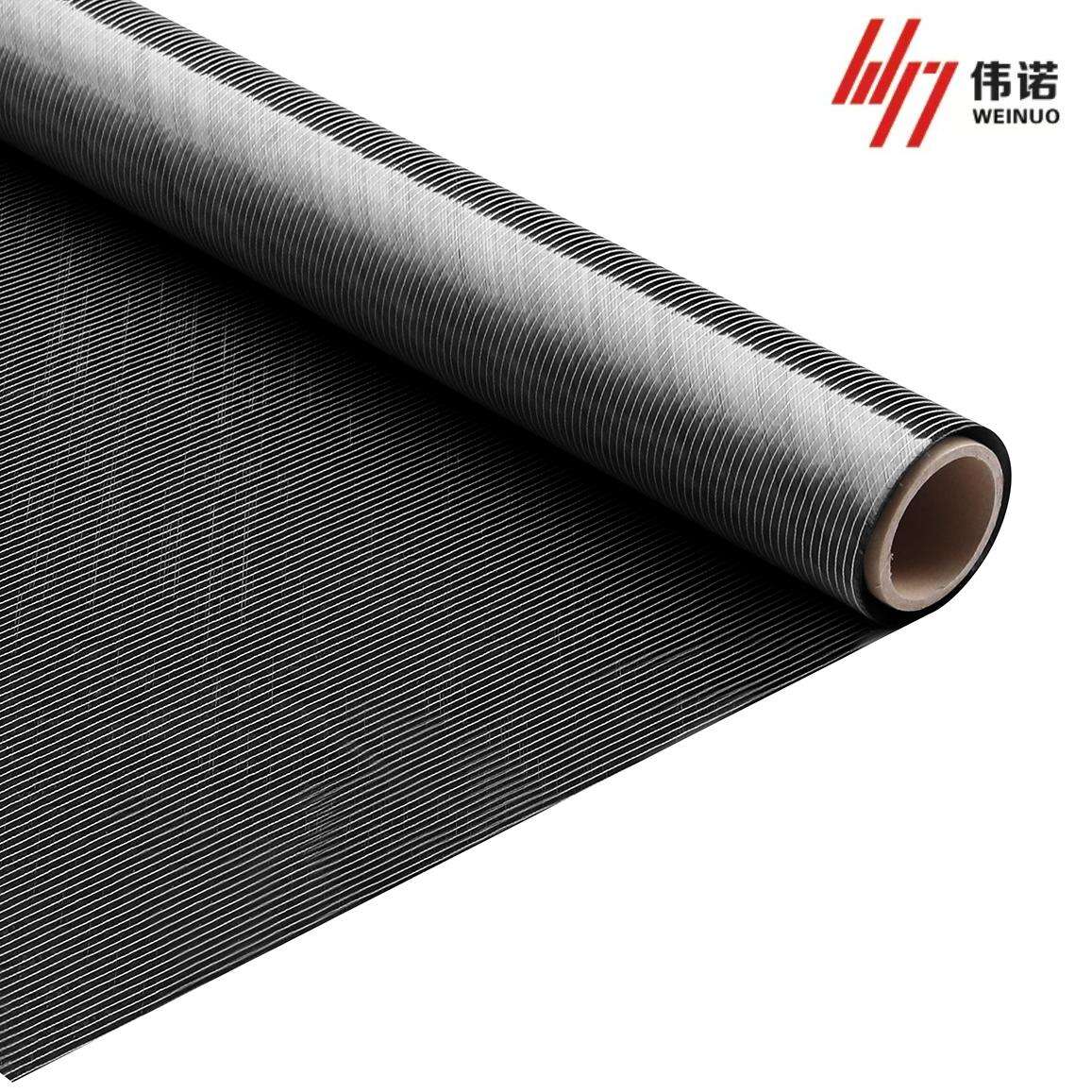

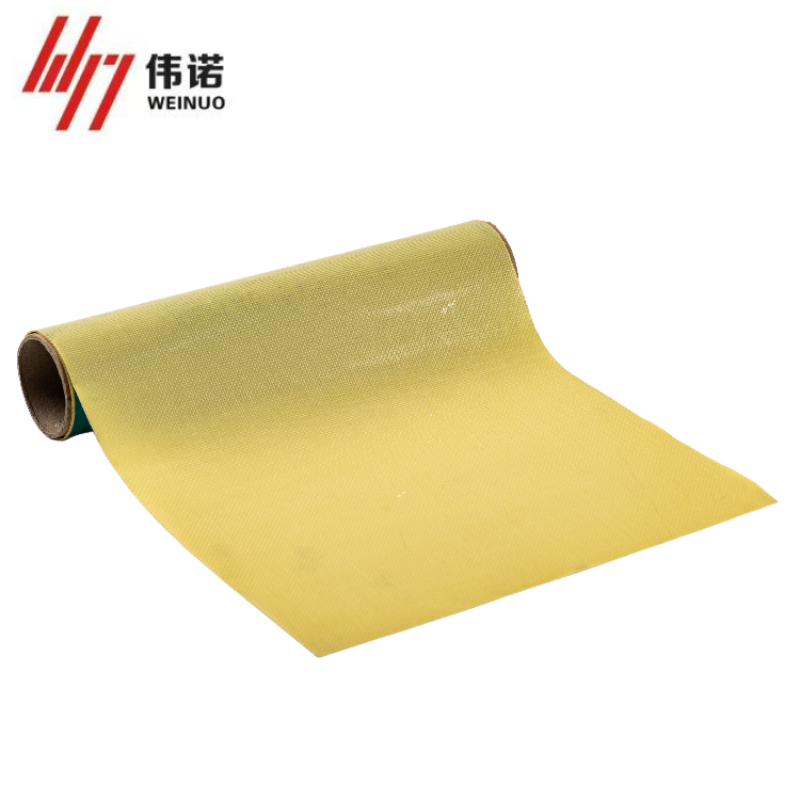

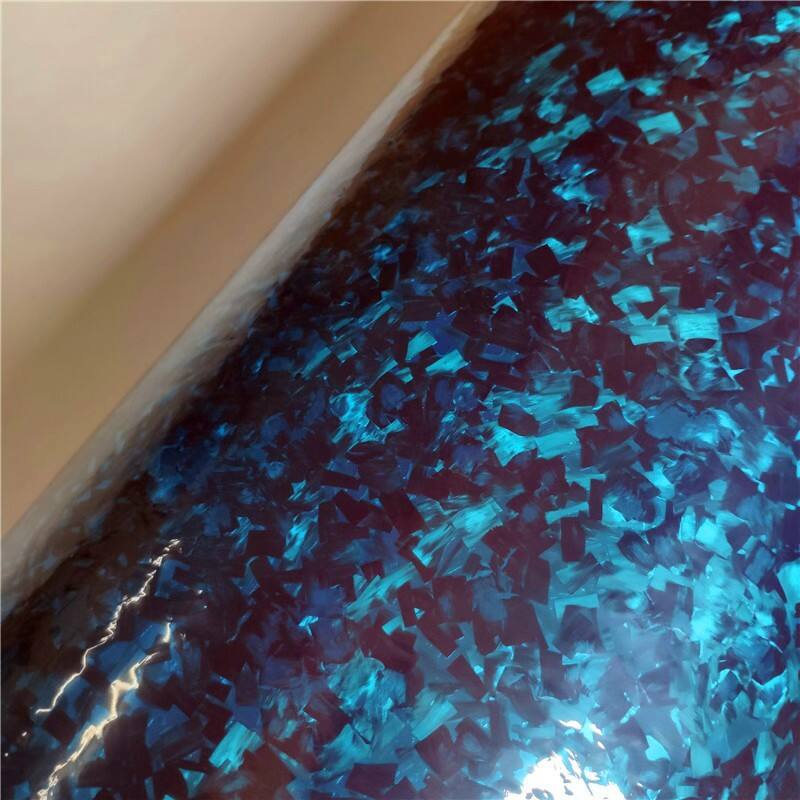

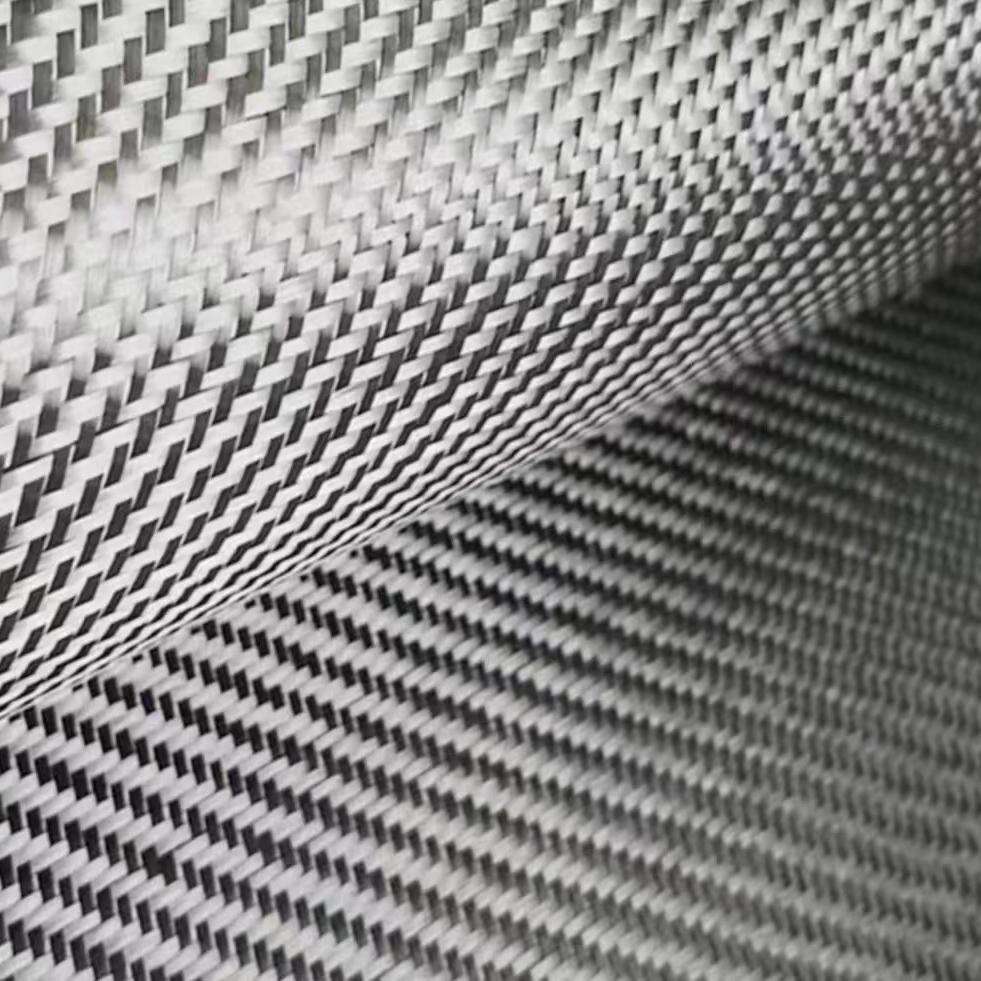

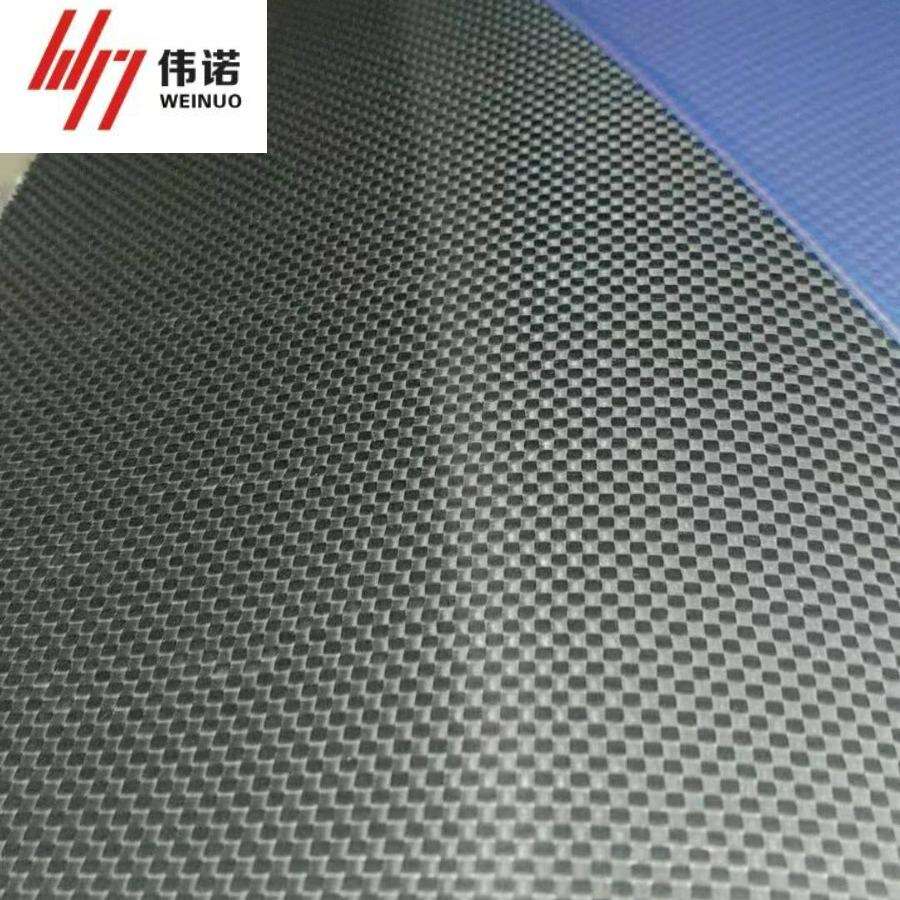

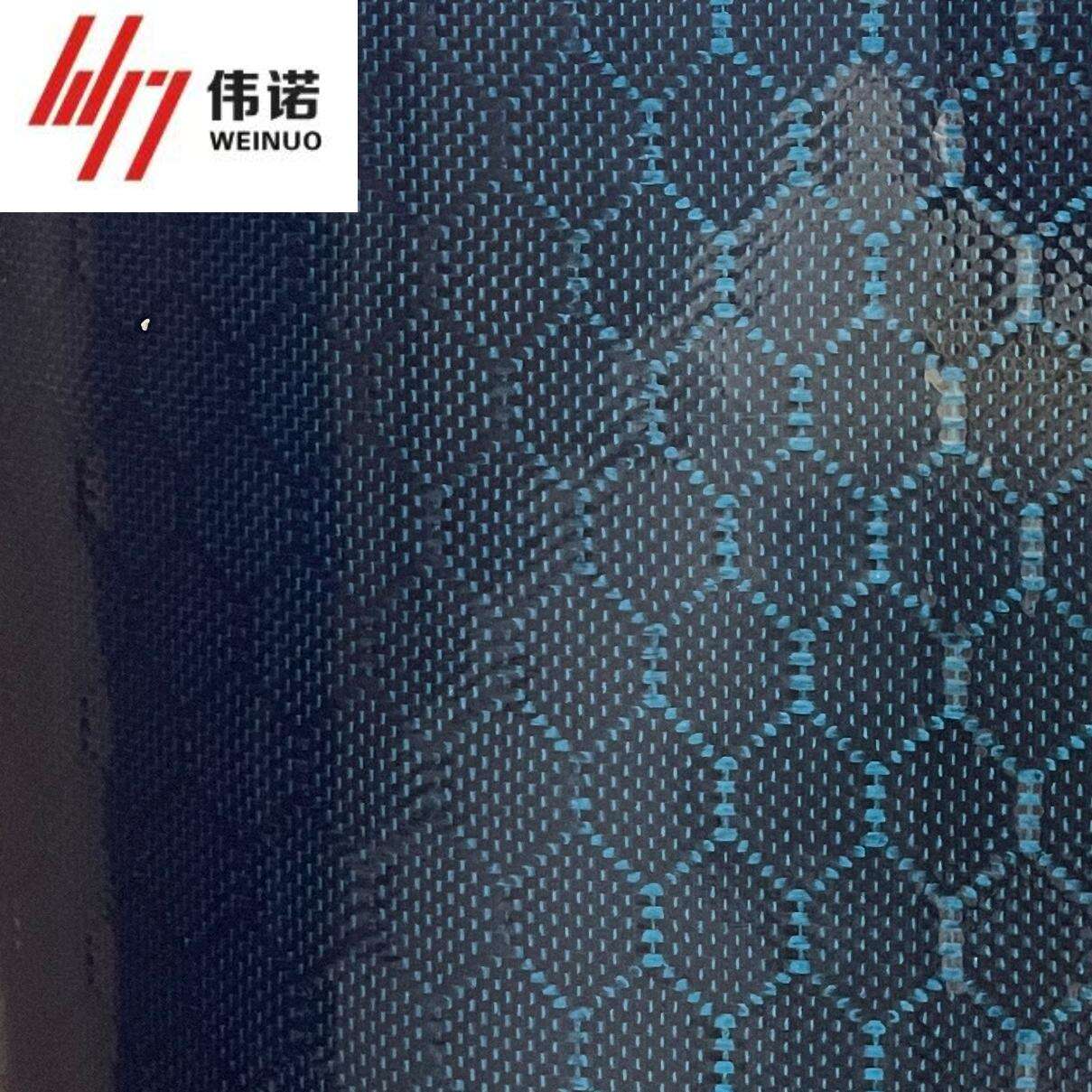

The adaptability of our prepreg carbon fiber opens up numerous possibilities across various industries and applications. The material's customizable properties allow for optimization in aerospace, automotive, marine, and sporting goods applications. Different fiber weights, weave patterns, and resin systems can be selected to meet specific performance requirements, from high-temperature resistance to impact absorption. The material's excellent surface finish capabilities make it particularly suitable for visible applications where aesthetics are important. Its ability to be processed using various manufacturing methods, including autoclave, out-of-autoclave, and press molding, provides flexibility in production approaches.