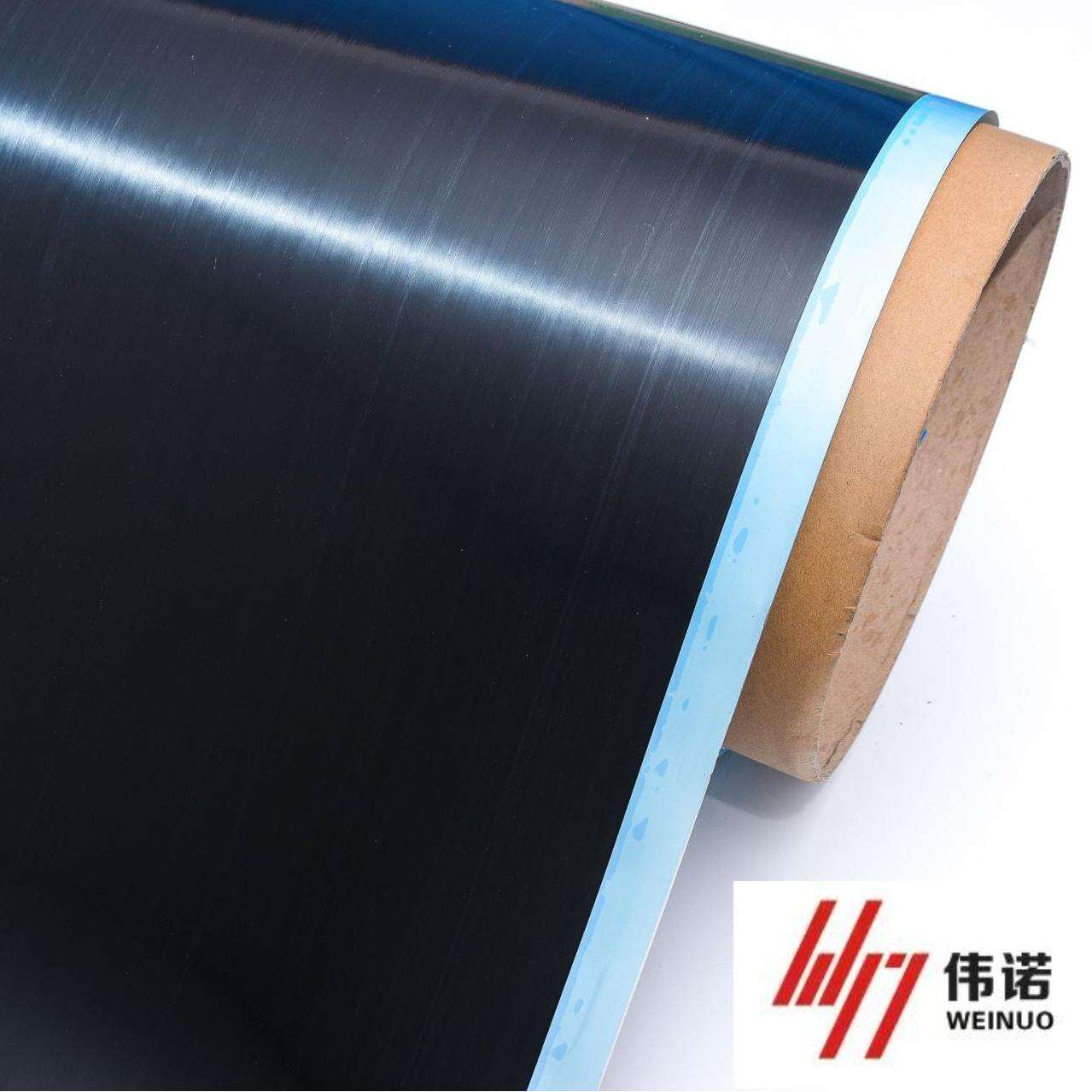

carbon fiber prepreg manufacturer

A carbon fiber prepreg manufacturer specializes in producing advanced composite materials that combine high-performance carbon fibers with precisely engineered resin systems. These facilities utilize state-of-the-art equipment and controlled environments to create pre-impregnated fiber materials that offer exceptional strength-to-weight ratios and consistent quality. The manufacturing process involves carefully measuring and combining specific quantities of carbon fiber and resin matrices, ensuring uniform distribution and optimal fiber-to-resin ratios. Modern facilities employ sophisticated temperature and humidity control systems, clean room environments, and automated processing equipment to maintain product integrity. These manufacturers typically offer various fiber types, weave patterns, and resin systems to meet diverse application requirements across industries such as aerospace, automotive, sports equipment, and industrial applications. Quality control measures include regular testing of mechanical properties, resin content analysis, and dimensional accuracy verification. The facility's capabilities often extend to custom formulations, allowing them to develop specific prepreg solutions for unique customer requirements. Advanced storage and handling systems maintain material freshness and properties, while technical support teams assist customers in optimizing their manufacturing processes for maximum efficiency and product performance.