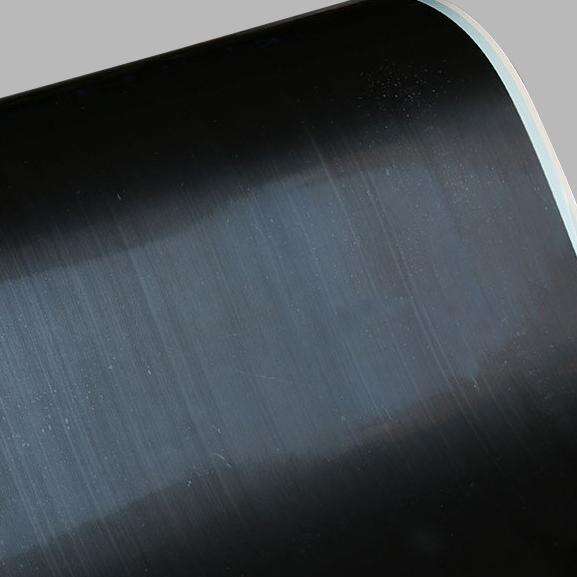

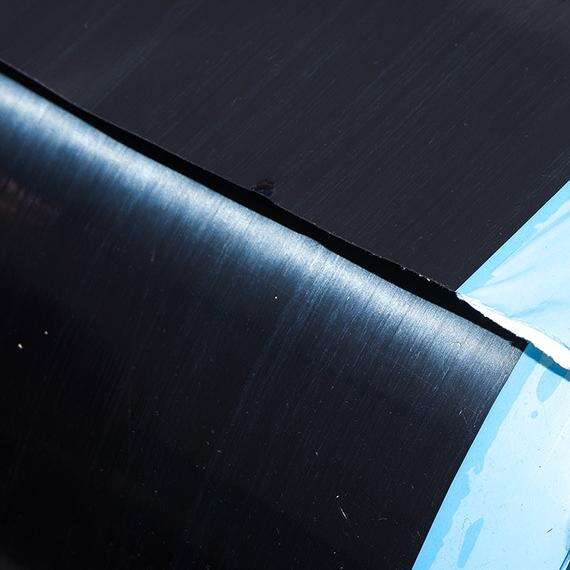

carbon fiber prepreg factory

A carbon fiber prepreg factory represents a cutting-edge manufacturing facility dedicated to producing high-quality pre-impregnated composite materials. These facilities utilize advanced automation systems and precise environmental controls to combine carbon fiber reinforcements with carefully formulated resin systems. The factory maintains specialized clean rooms with controlled temperature and humidity levels, ensuring consistent product quality. The manufacturing process involves sophisticated resin application systems, precision tension controls, and advanced curing technologies. Multiple production lines operate simultaneously, capable of handling various fiber types and resin systems to meet diverse customer specifications. Quality control laboratories equipped with state-of-the-art testing equipment monitor material properties throughout the production process. The facility includes dedicated storage areas with controlled environments for both raw materials and finished products, maintaining optimal conditions for prepreg shelf life. Advanced cutting and slitting equipment allows for customized product dimensions, while automated packaging systems ensure proper protection during storage and shipping. The factory's capabilities extend to producing prepregs for aerospace, automotive, sporting goods, and industrial applications, with the flexibility to adjust processing parameters for specific performance requirements.