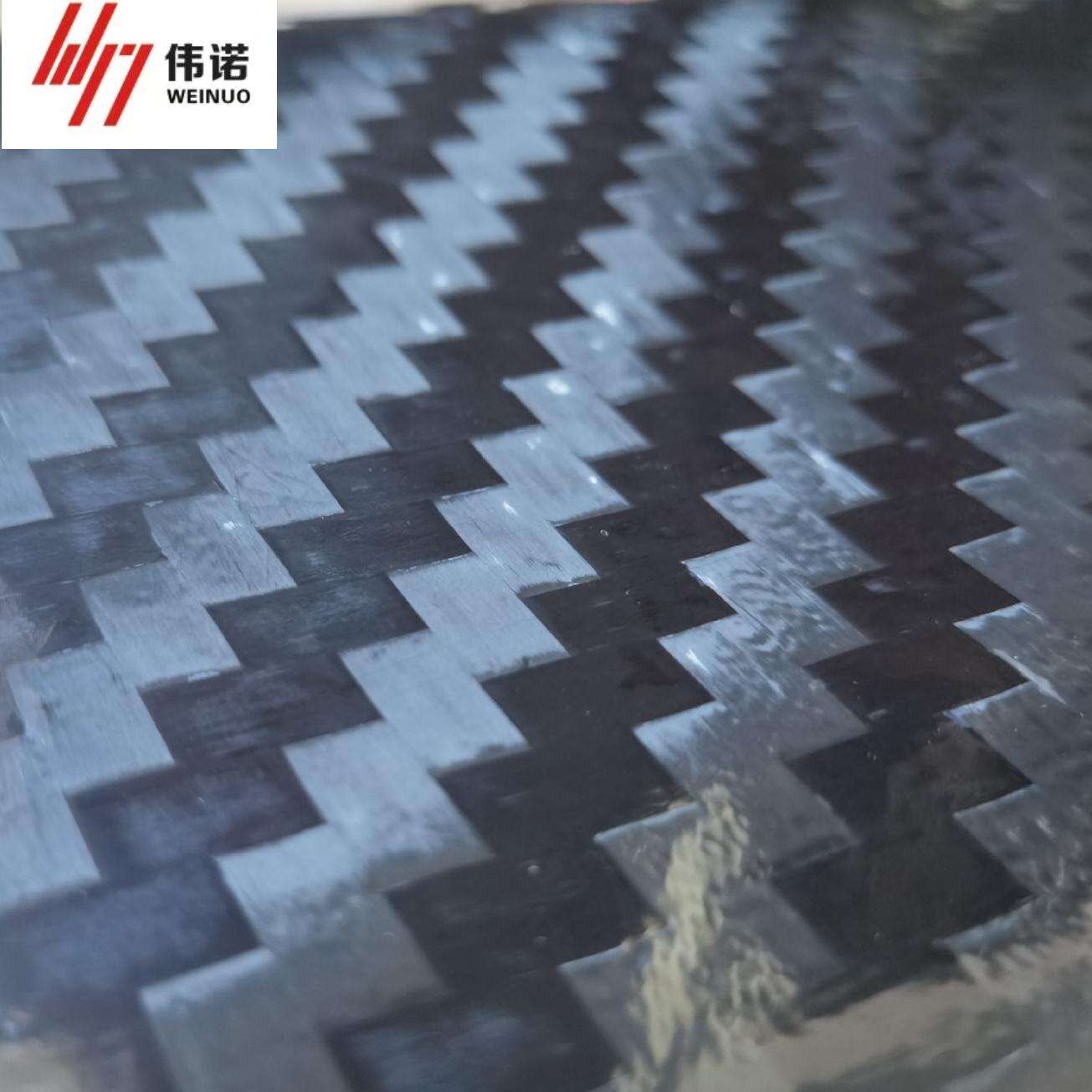

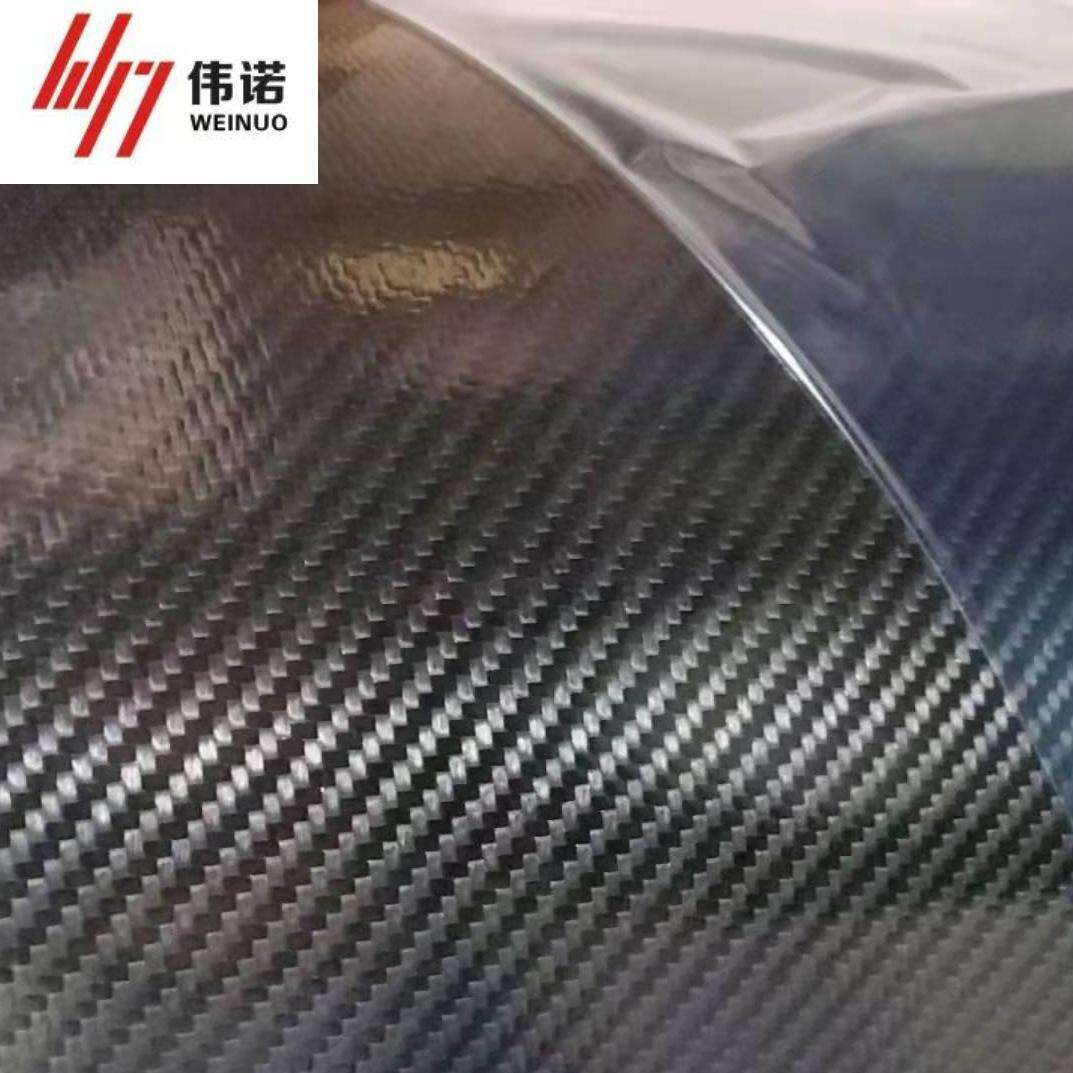

fast cure carbon fiber prepreg

Fast cure carbon fiber prepreg represents a significant advancement in composite materials technology, offering manufacturers a high-performance solution for rapid production cycles. This innovative material consists of carbon fiber reinforcement pre-impregnated with a specialized resin system designed to cure significantly faster than traditional prepregs. The material maintains excellent mechanical properties while reducing the overall processing time from hours to minutes. These prepregs typically cure at temperatures between 120-150°C, achieving full consolidation in 5-15 minutes, compared to conventional systems that may require 1-2 hours. The fast-curing capability is achieved through advanced chemistry and carefully controlled resin formulations that provide optimal flow characteristics and cure kinetics. The material offers exceptional strength-to-weight ratios, superior surface finish, and consistent fiber-to-resin content throughout the product. It's particularly valuable in industries where production efficiency is crucial, such as automotive manufacturing, sporting goods, and industrial applications. The material's rapid processing characteristics make it ideal for high-volume production while maintaining the superior mechanical properties expected from carbon fiber composites.