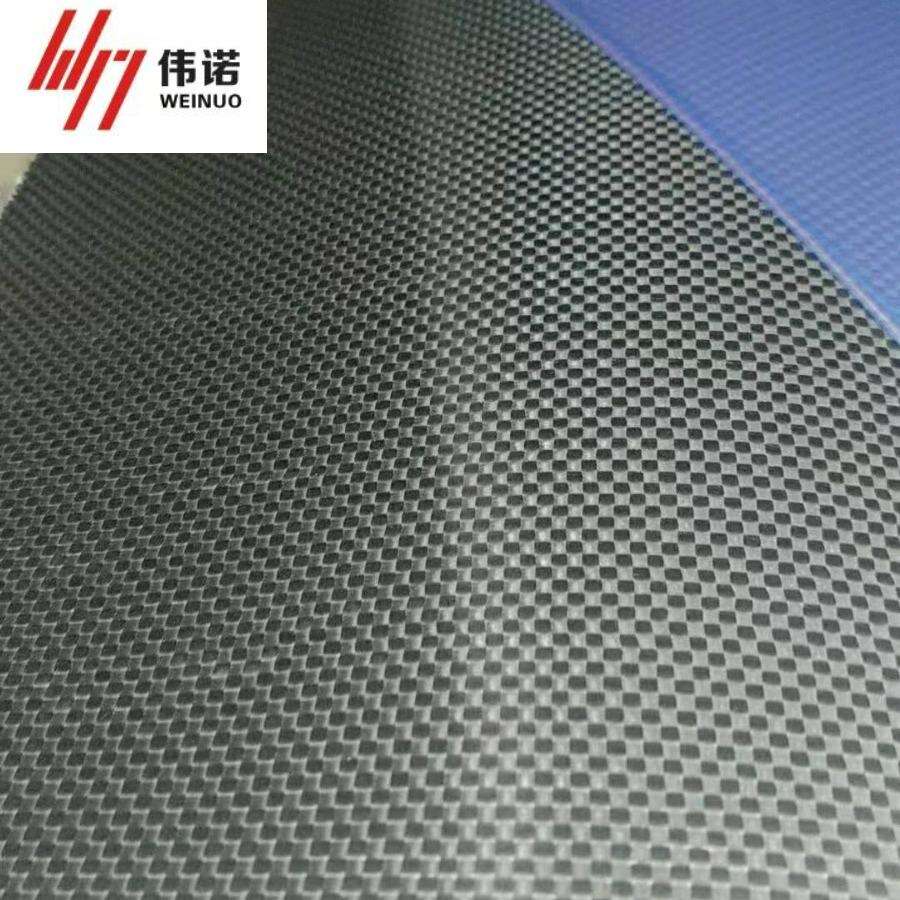

ud 100g carbon fiber prepreg

The UD 100g carbon fiber prepreg represents a cutting-edge advancement in composite materials technology, offering an exceptional combination of strength, lightweight properties, and versatility. This unidirectional prepreg features precisely aligned carbon fibers pre-impregnated with high-performance resin systems, weighing 100 grams per square meter. The material's unidirectional configuration allows for maximum strength in the fiber direction, making it particularly valuable for applications requiring specific load-bearing capabilities. Engineers and manufacturers appreciate its consistent fiber distribution and optimal resin content, which ensures reliable performance and ease of processing. The prepreg's controlled resin content and excellent tack characteristics facilitate layup operations while minimizing void content in final components. Its applications span across various industries, including aerospace, automotive, sporting goods, and high-performance industrial applications. The material exhibits exceptional fatigue resistance, superior dimensional stability, and remarkable mechanical properties, making it ideal for structural components that demand high strength-to-weight ratios. When properly stored and handled, the UD 100g carbon fiber prepreg maintains its processing characteristics and delivers consistent results in both autoclave and out-of-autoclave curing processes.