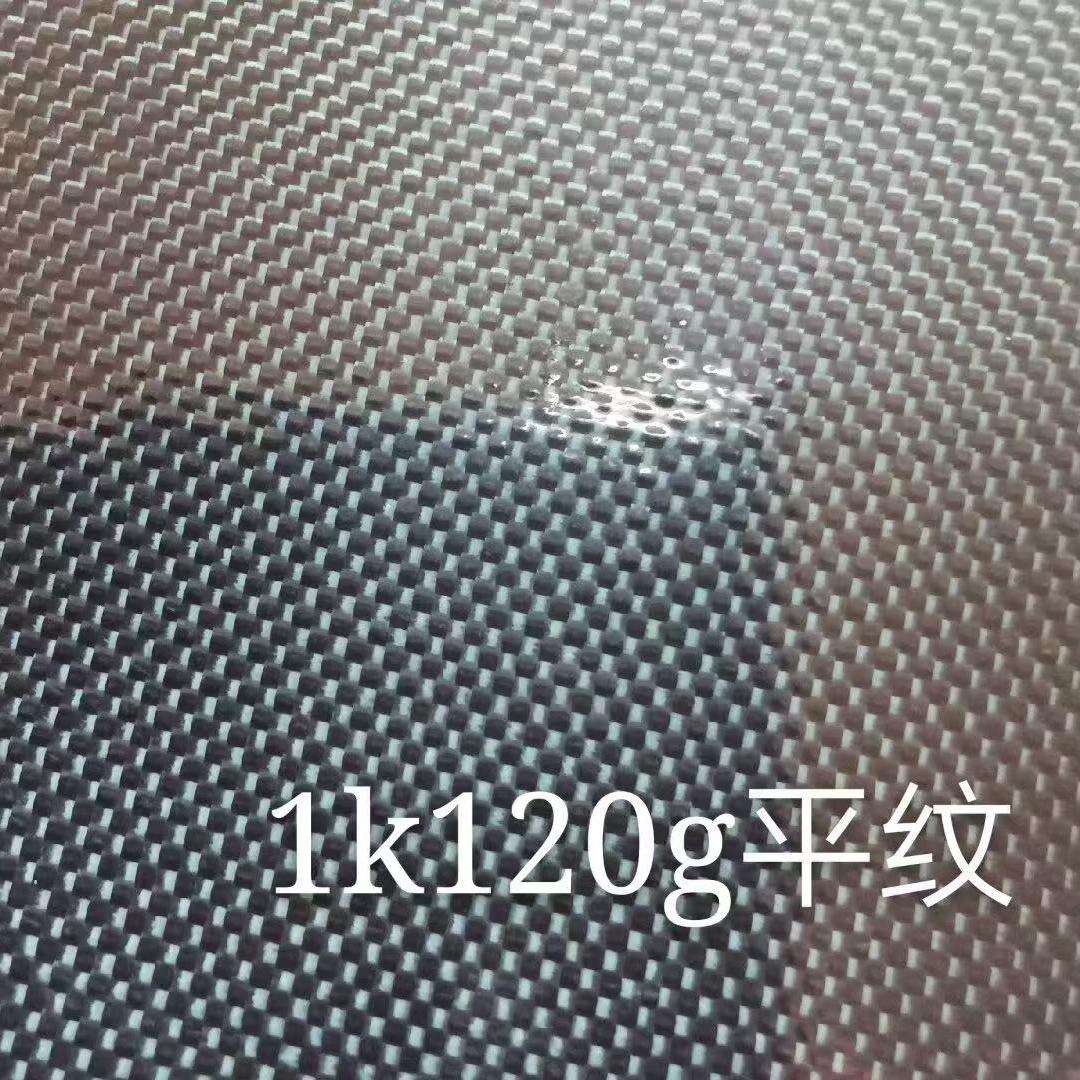

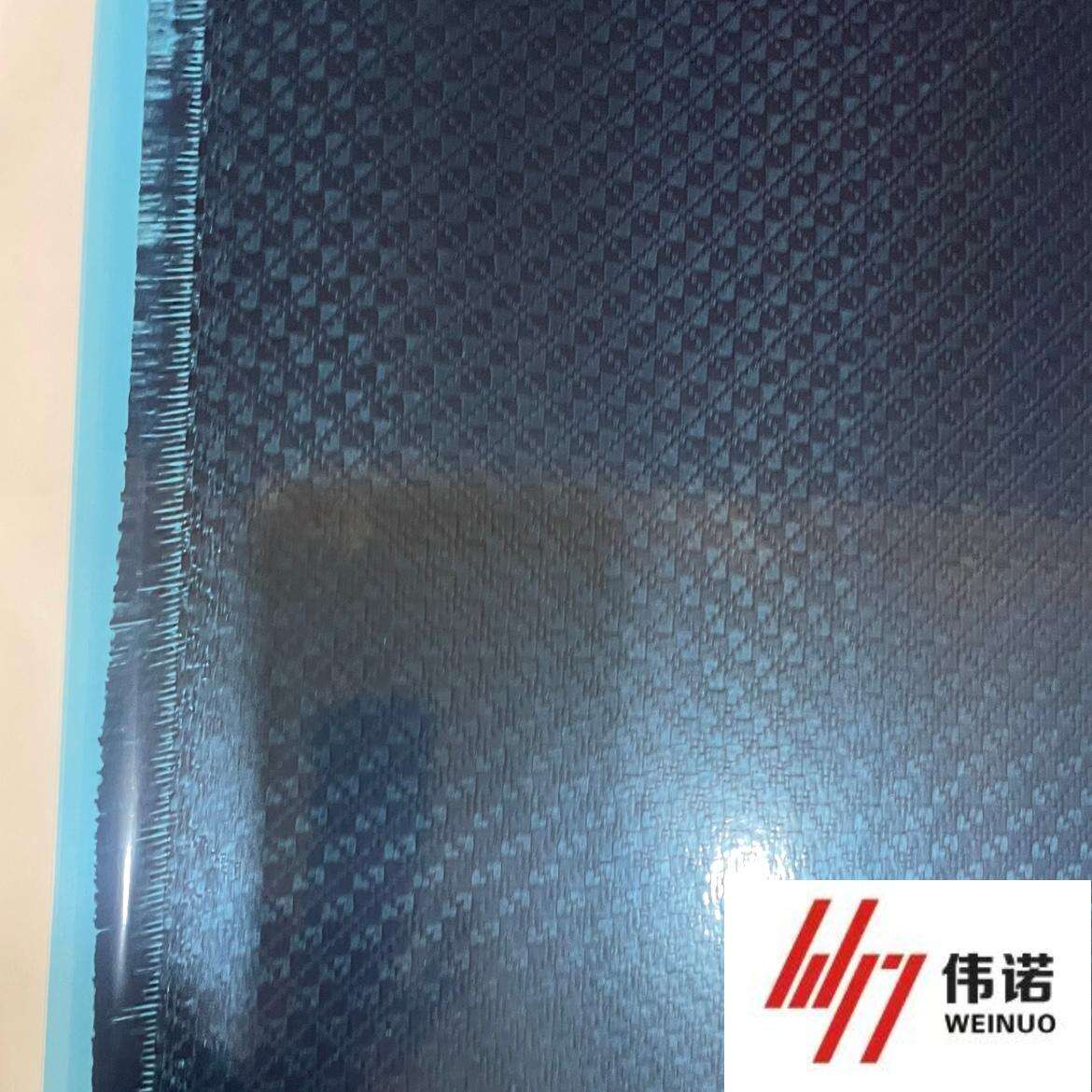

prepreg carbon fiber fabric

Prepreg carbon fiber fabric represents a cutting-edge advancement in composite materials technology, combining high-strength carbon fibers with pre-impregnated resin systems. This sophisticated material consists of carefully aligned carbon fiber reinforcements that have been precisely pre-impregnated with a thermoset resin system under controlled conditions. The pre-impregnation process ensures optimal fiber-to-resin ratios, eliminating the complexities and inconsistencies often associated with wet layup processes. These materials are engineered to deliver exceptional mechanical properties, including superior strength-to-weight ratios, outstanding fatigue resistance, and remarkable dimensional stability. In manufacturing settings, prepreg carbon fiber fabrics are typically stored in controlled environments and require specific temperature conditions for optimal handling and curing. When properly cured, these materials create incredibly strong, lightweight structures that find applications across numerous high-performance industries. The aerospace sector utilizes these materials extensively in aircraft components, while the automotive industry implements them in racing cars and luxury vehicles. Additionally, prepreg carbon fiber fabrics have gained significant traction in sporting goods manufacturing, particularly in high-end bicycles, golf clubs, and tennis rackets. The material's versatility extends to architectural applications, medical devices, and industrial equipment where weight reduction and structural integrity are paramount.