carbon fiber prepreg supplier

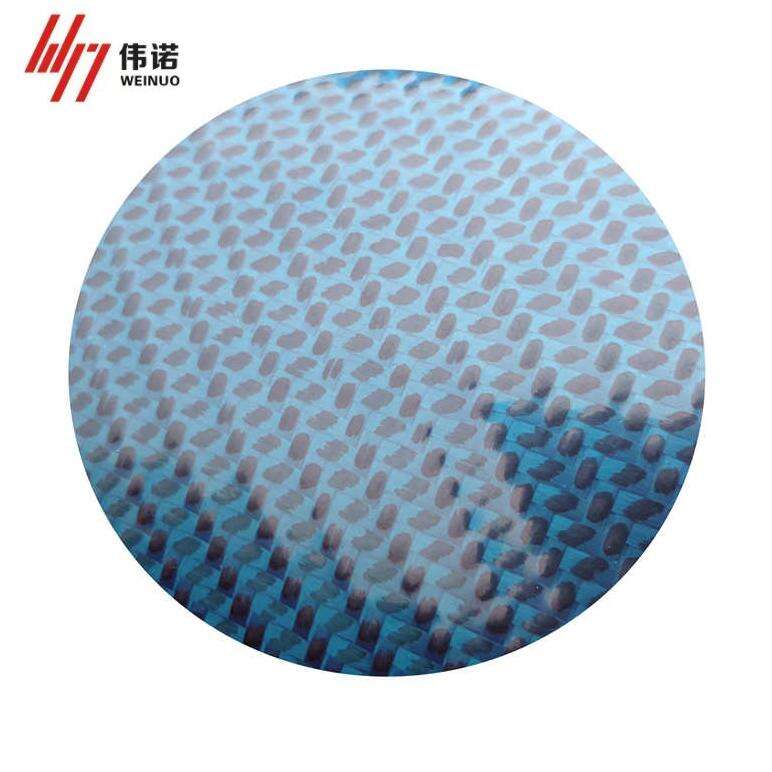

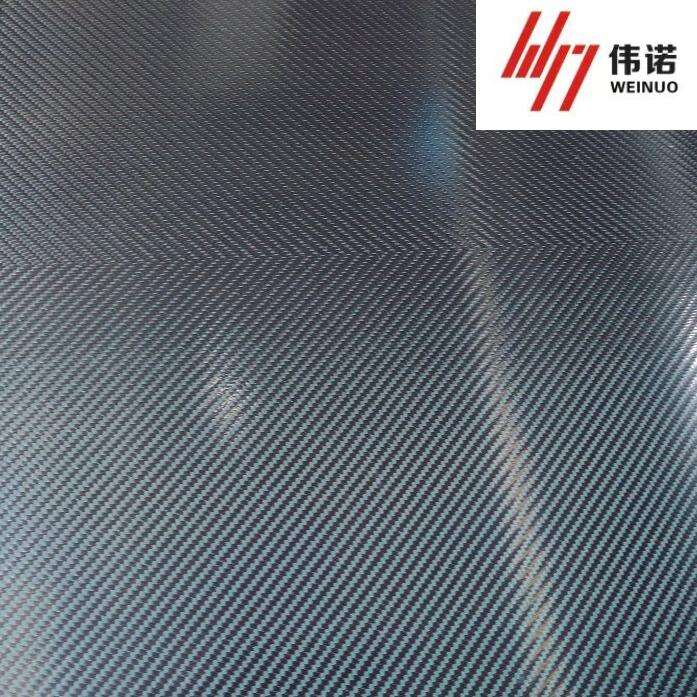

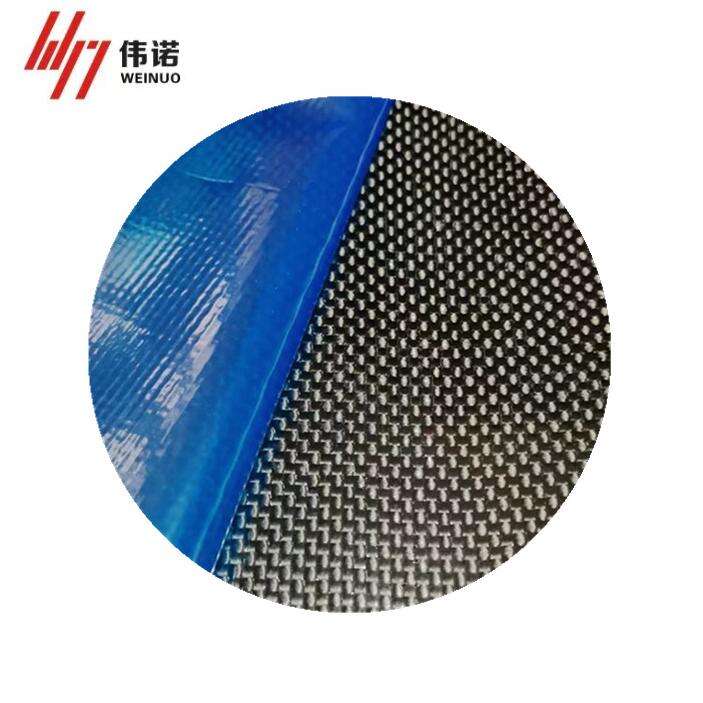

A carbon fiber prepreg supplier stands as a crucial partner in advanced manufacturing, providing high-quality pre-impregnated composite materials that combine carbon fiber reinforcement with carefully formulated resin systems. These specialized suppliers maintain state-of-the-art facilities equipped with precise temperature and humidity controls to ensure optimal material storage and handling. They offer an extensive range of prepreg materials, including unidirectional tapes, woven fabrics, and specialized formats designed for specific applications. The supplier's role extends beyond mere distribution, encompassing technical support, quality assurance, and often customized solutions for unique manufacturing requirements. Their expertise includes managing the complex logistics of temperature-controlled storage and transportation, ensuring that materials maintain their prescribed properties from production to final application. Modern carbon fiber prepreg suppliers typically maintain comprehensive testing facilities to verify material properties and provide detailed documentation for aerospace, automotive, and other high-performance applications. They often collaborate closely with customers during material selection and process optimization, offering valuable insights into handling techniques, cure cycles, and performance characteristics. The supplier's capabilities usually include cut-to-size services, ply orientation optimization, and the ability to provide materials with varying fiber weights, resin contents, and tack levels to meet diverse manufacturing needs.