carbon fiber prepreg types

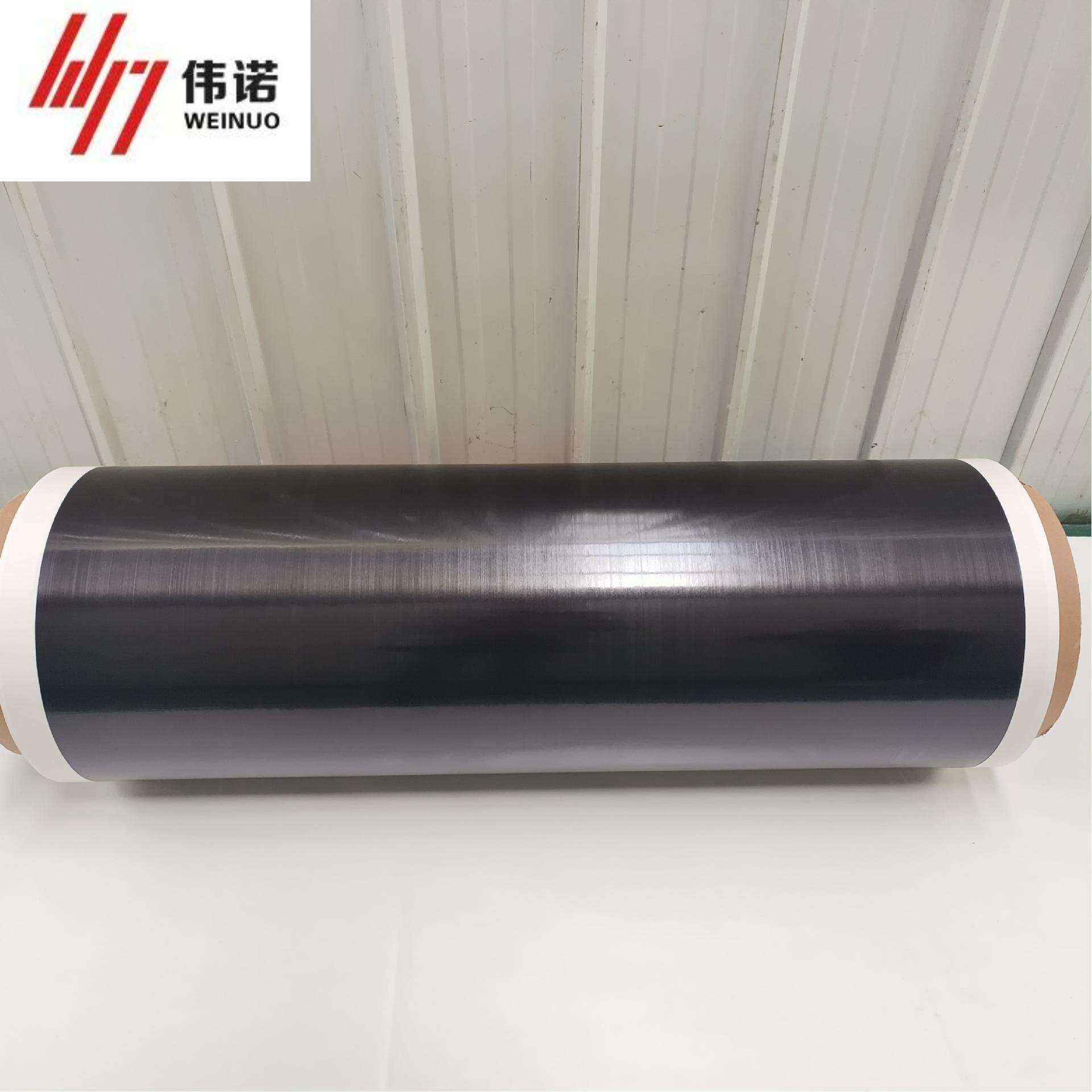

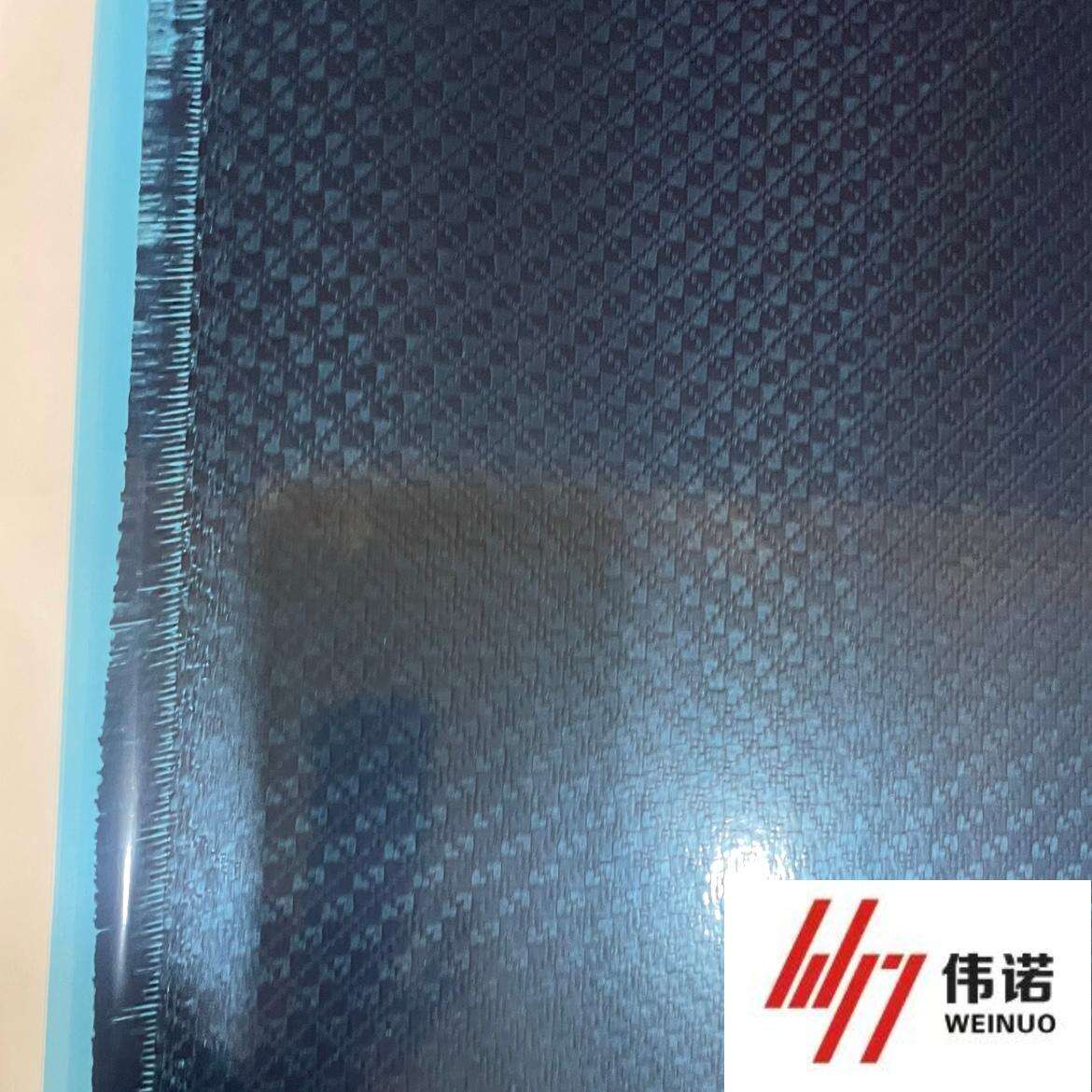

Carbon fiber prepreg types represent advanced composite materials that combine high-performance carbon fibers with pre-impregnated resin systems. These materials come in various forms, including unidirectional (UD), woven fabric, and multiaxial configurations. UD prepregs offer maximum strength in a single direction, making them ideal for applications requiring specific load-bearing capabilities. Woven fabric prepregs provide balanced properties in multiple directions, while multiaxial variants deliver enhanced structural performance through optimized fiber orientation. The resin systems used in these prepregs can be tailored to specific requirements, ranging from epoxy-based systems for general applications to high-temperature resistant formulations for aerospace use. Each type undergoes precise manufacturing processes that control fiber-to-resin ratios, ensuring consistent quality and performance. These materials typically require controlled storage conditions and specific curing cycles to achieve optimal mechanical properties. Modern carbon fiber prepregs incorporate advanced features such as out-life indicators, improved tack properties, and enhanced processing characteristics, making them increasingly versatile in various industrial applications.