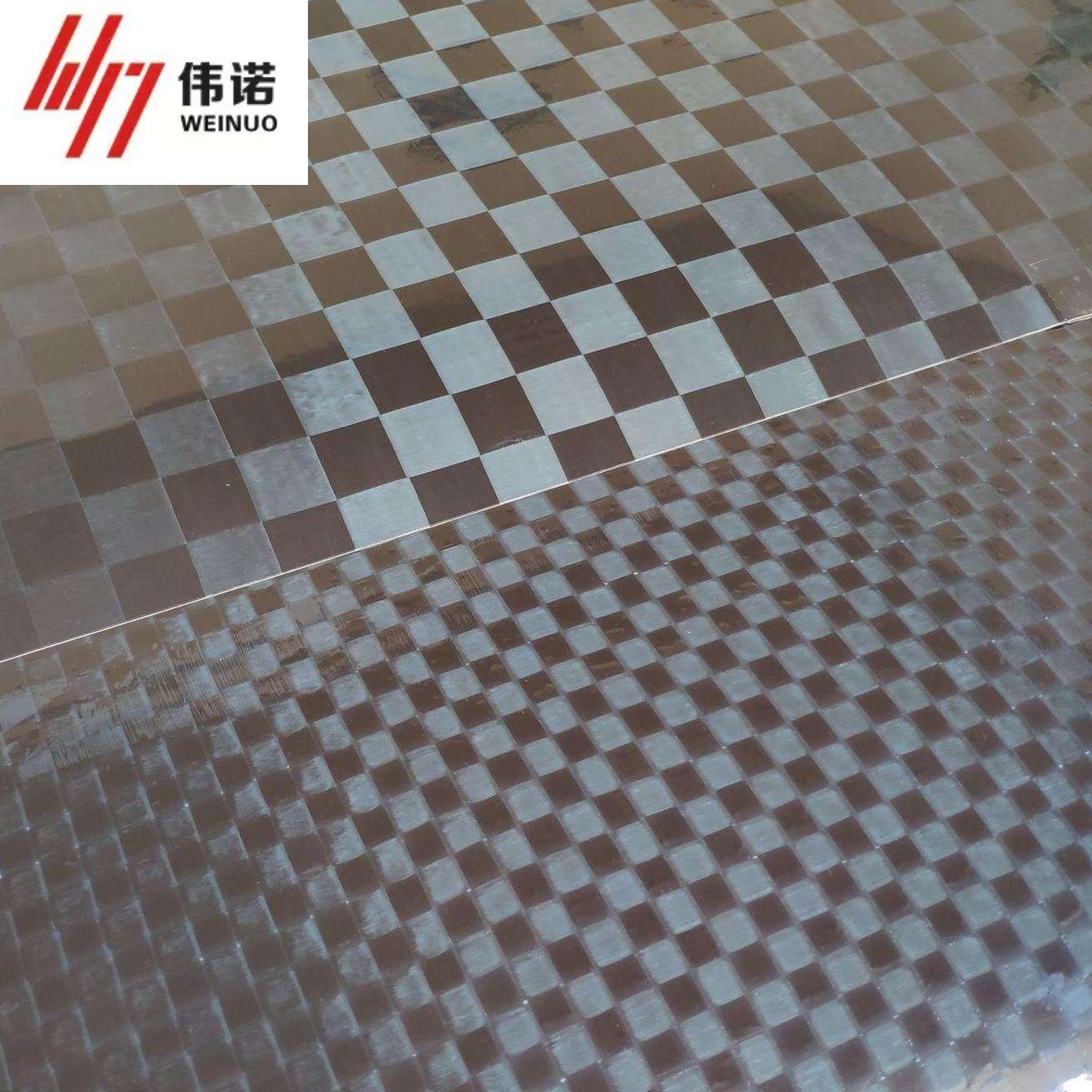

carbon fiber prepreg roll

A carbon fiber prepreg roll represents a cutting-edge composite material that combines high-strength carbon fibers with pre-impregnated resin systems. This advanced material form consists of precisely aligned carbon fibers that have been pre-impregnated with a carefully formulated resin matrix, creating a ready-to-use composite material that's ideal for manufacturing high-performance parts. The roll format allows for efficient storage, handling, and application in various manufacturing processes. These prepreg rolls are engineered to maintain consistent fiber-to-resin ratios throughout the material, ensuring uniform properties in the final product. The material typically requires controlled storage conditions, usually at low temperatures, to prevent premature curing of the resin system. When properly handled, carbon fiber prepreg rolls offer exceptional mechanical properties, including superior strength-to-weight ratios, excellent fatigue resistance, and remarkable dimensional stability. The material finds extensive applications in aerospace, automotive, sporting goods, and industrial sectors where lightweight yet robust components are essential. The manufacturing process involves sophisticated temperature and pressure controls to achieve optimal curing and consolidation, resulting in components with superior surface finish and mechanical properties.