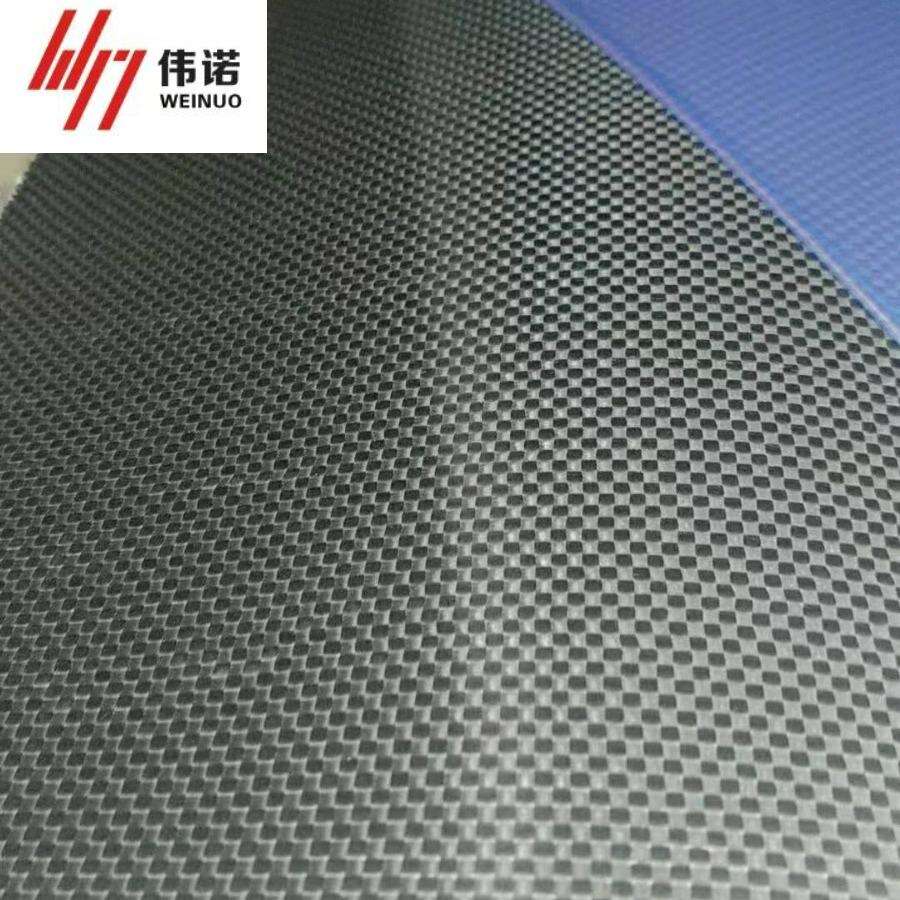

chopped carbon fiber prepreg

Chopped carbon fiber prepreg represents a cutting-edge material solution that combines the strength of carbon fiber with the convenience of preimpregnated resin systems. This innovative material consists of precisely cut carbon fiber strands that have been pre-impregnated with a carefully formulated resin matrix. The material offers exceptional strength-to-weight ratios while maintaining processing flexibility that makes it ideal for complex manufacturing applications. The chopped format allows for enhanced moldability and the ability to fill intricate mold geometries, making it particularly valuable in automated manufacturing processes. The prepreg nature ensures consistent resin content and superior fiber wet-out, leading to more reliable final part properties. These materials typically come in standardized lengths ranging from 3mm to 50mm, allowing manufacturers to select the optimal size for their specific application requirements. The material's unique properties make it particularly suitable for high-performance applications in automotive, aerospace, and industrial sectors where weight reduction and structural integrity are crucial. The controlled fiber orientation and uniform resin distribution result in enhanced mechanical properties and superior surface finish in the final products.