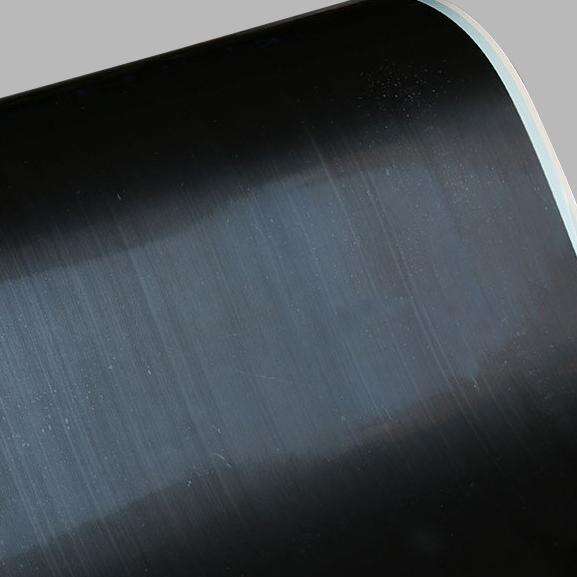

carbon fiber prepreg manufacturers

Carbon fiber prepreg manufacturers play a crucial role in modern advanced materials production, specializing in the creation of pre-impregnated composite fibers that revolutionize various industries. These manufacturers utilize cutting-edge technology to combine high-strength carbon fibers with carefully formulated resin systems, creating materials that offer unprecedented strength-to-weight ratios. The manufacturing process involves precise control of resin content, fiber orientation, and environmental conditions to ensure consistent quality. These facilities employ advanced clean room environments and sophisticated equipment for precise temperature and humidity control. The manufacturers typically offer a range of product specifications, including different fiber weights, resin systems, and cure temperatures to meet diverse application requirements. Their products find extensive use in aerospace, automotive, sporting goods, and industrial applications. Many manufacturers also provide custom solutions, working closely with clients to develop specific formulations that meet unique performance requirements. Quality control systems, including advanced testing facilities and strict documentation procedures, ensure that products meet or exceed industry standards. The manufacturers often maintain research and development departments focused on innovating new prepreg solutions and improving existing products. Their expertise extends beyond mere production to include technical support, material selection guidance, and processing recommendations for optimal results.