prepreg carbon fiber manufacturer

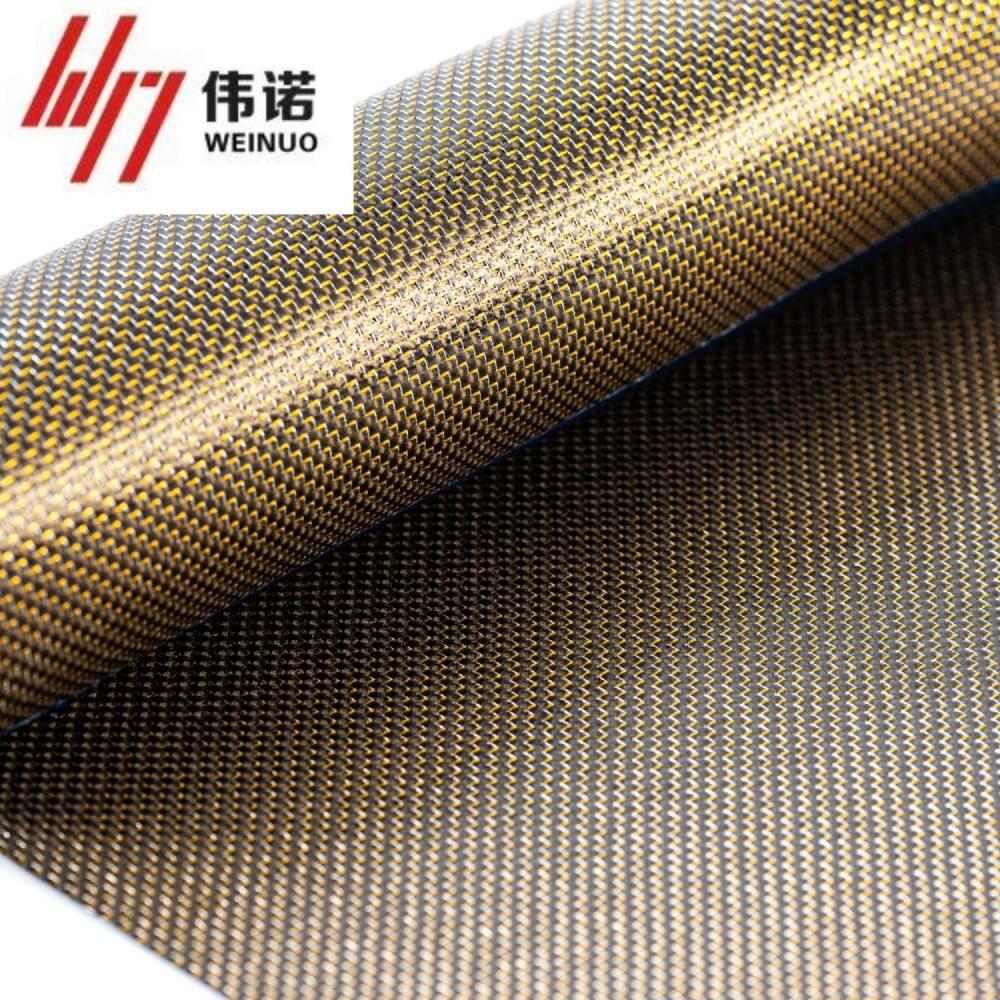

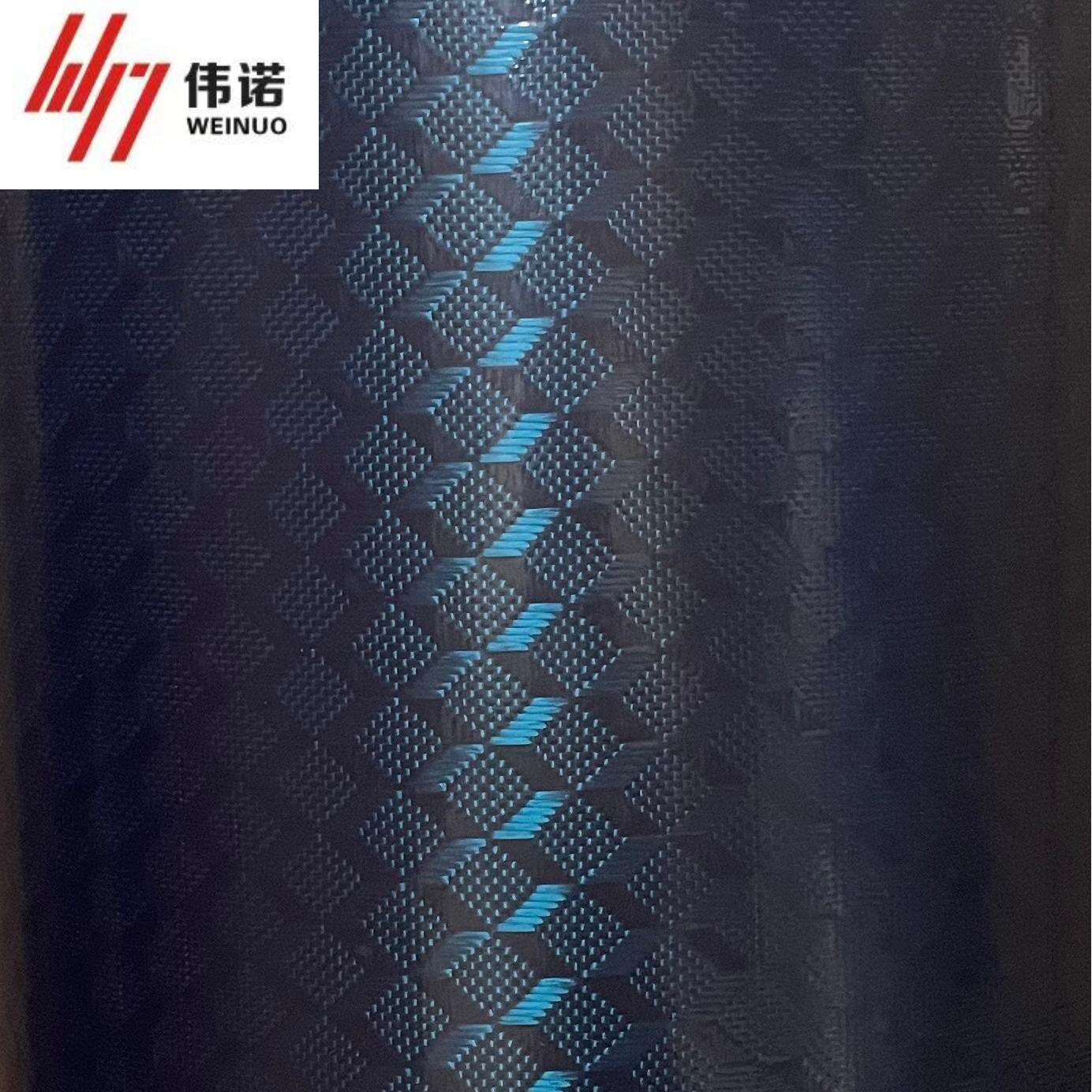

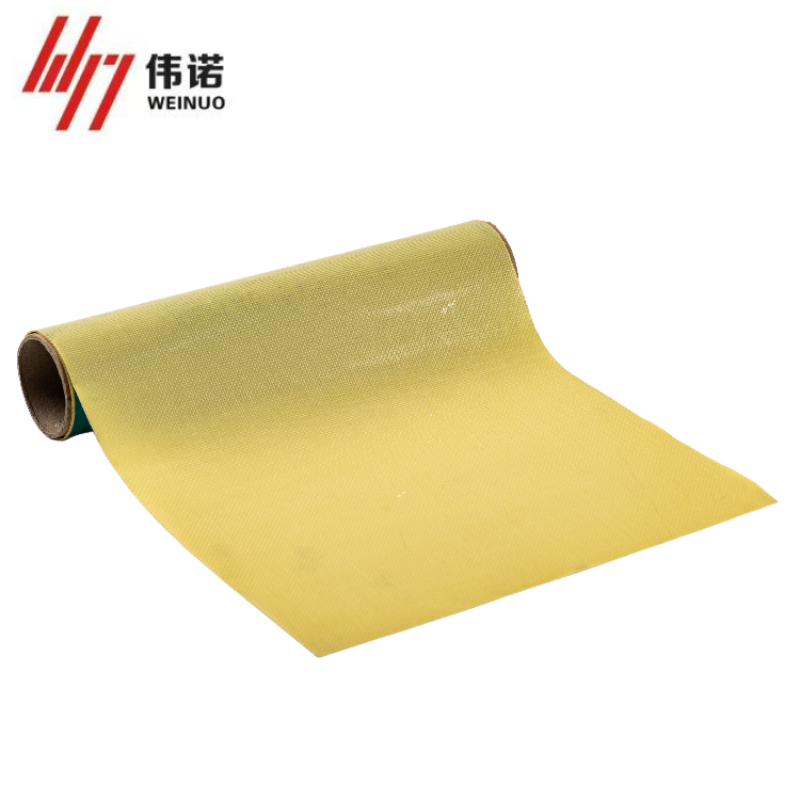

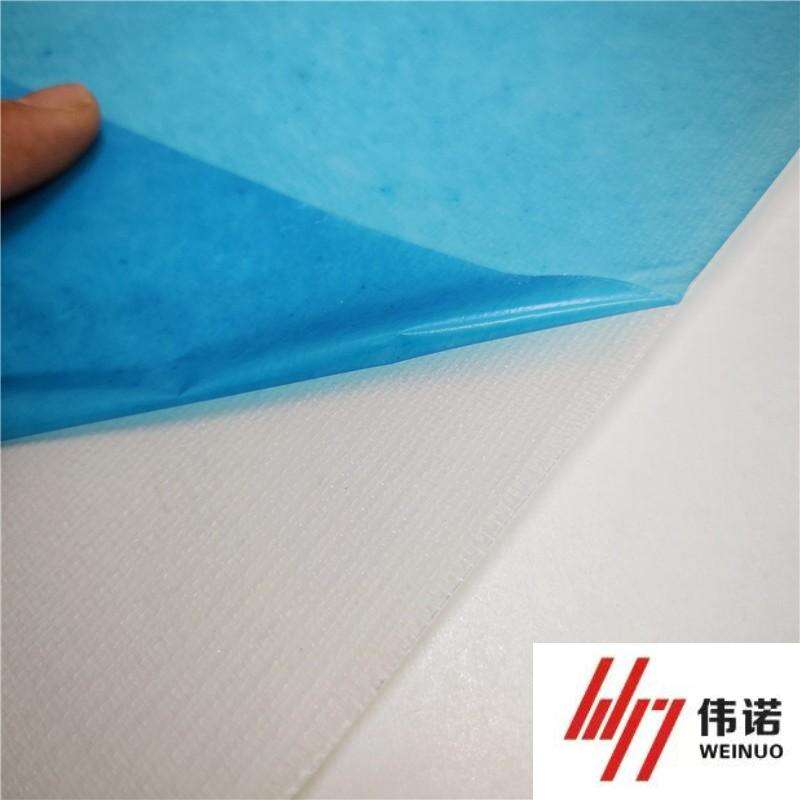

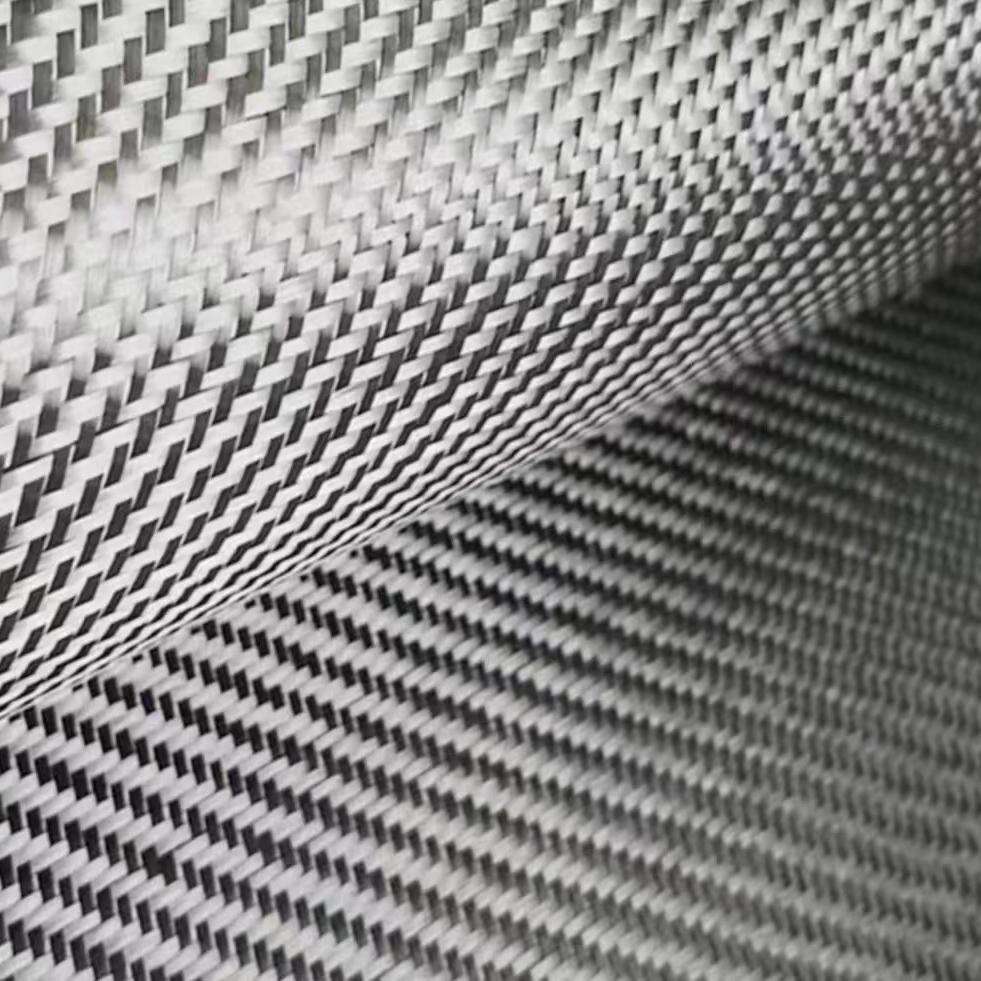

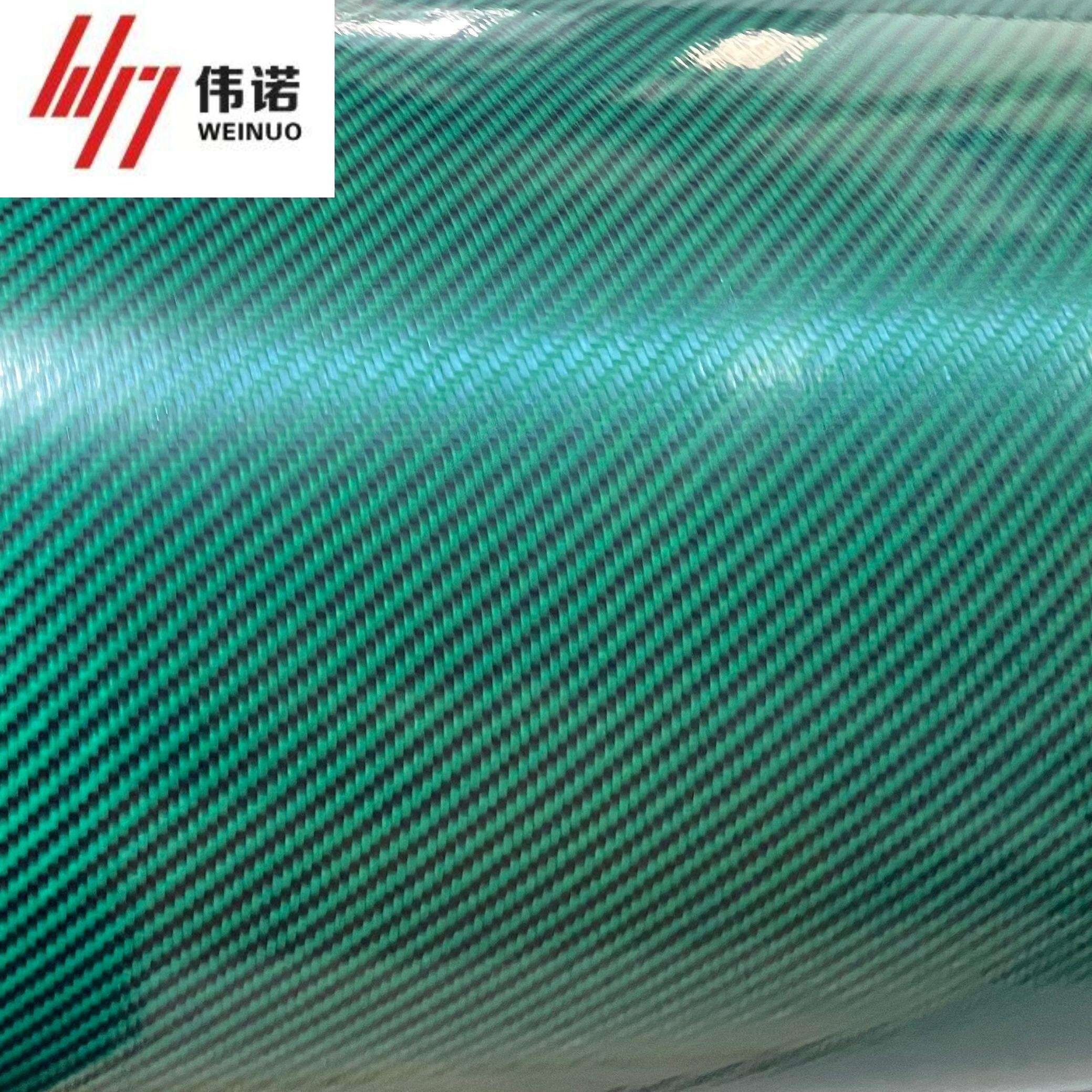

A prepreg carbon fiber manufacturer specializes in producing advanced composite materials that combine carbon fiber reinforcements with pre-impregnated resin systems. These facilities employ state-of-the-art manufacturing processes to create high-performance materials used across various industries. The manufacturing process involves precisely controlling temperature, pressure, and resin content to ensure consistent quality and optimal performance characteristics. Modern prepreg manufacturers utilize automated production lines equipped with sophisticated monitoring systems to maintain precise fiber alignment and uniform resin distribution. These facilities typically feature clean room environments, advanced quality control laboratories, and specialized storage areas with controlled temperature and humidity conditions. The manufacturer's capabilities often include multiple production lines capable of handling different fiber types, resin systems, and product specifications. They produce various formats including unidirectional tapes, woven fabrics, and custom layups tailored to specific applications. The facility's technical expertise extends to material characterization, mechanical testing, and product development support. Many manufacturers also offer value-added services such as kit cutting, custom packaging, and technical consulting to support their customers' specific requirements. The products find applications in aerospace, automotive, sporting goods, and industrial sectors, where high strength-to-weight ratio and superior performance are crucial.