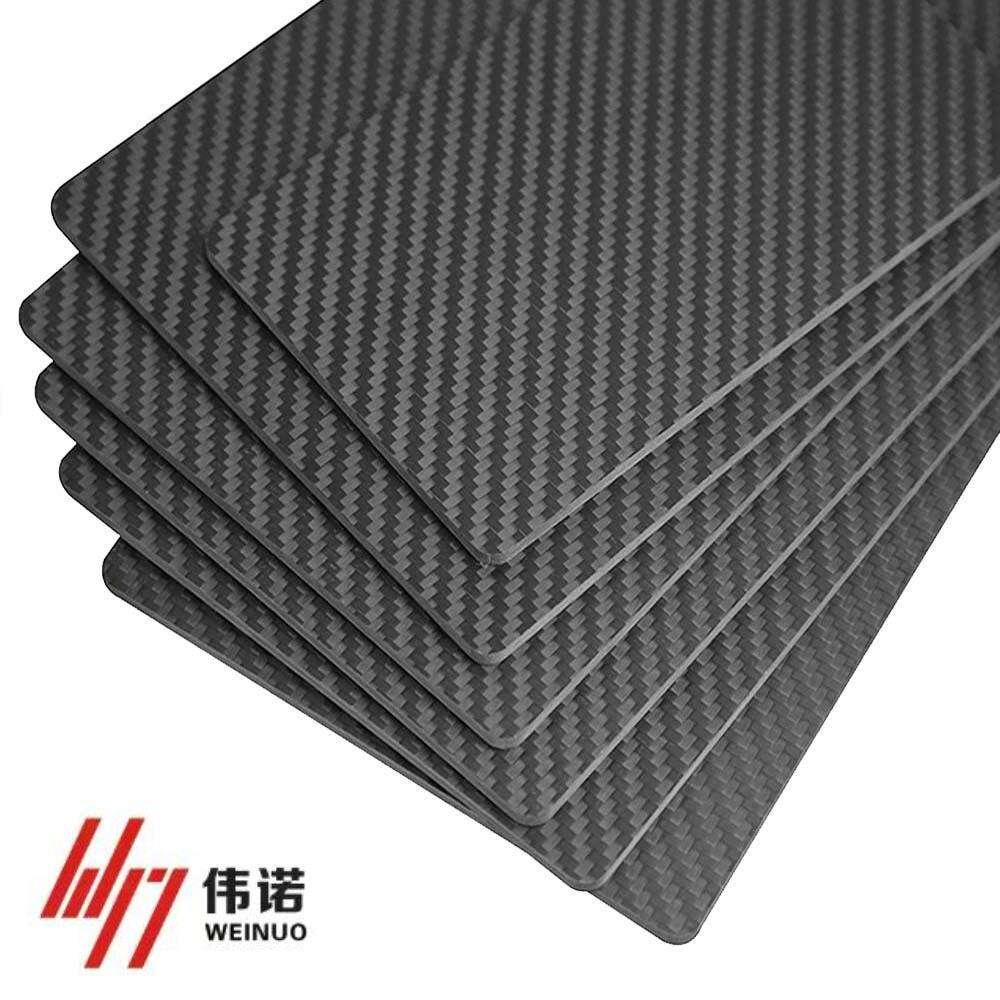

prepreg carbon fiber types

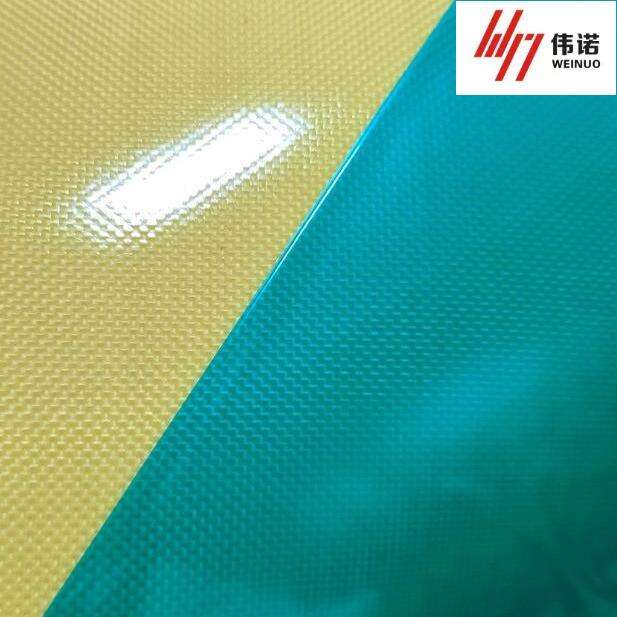

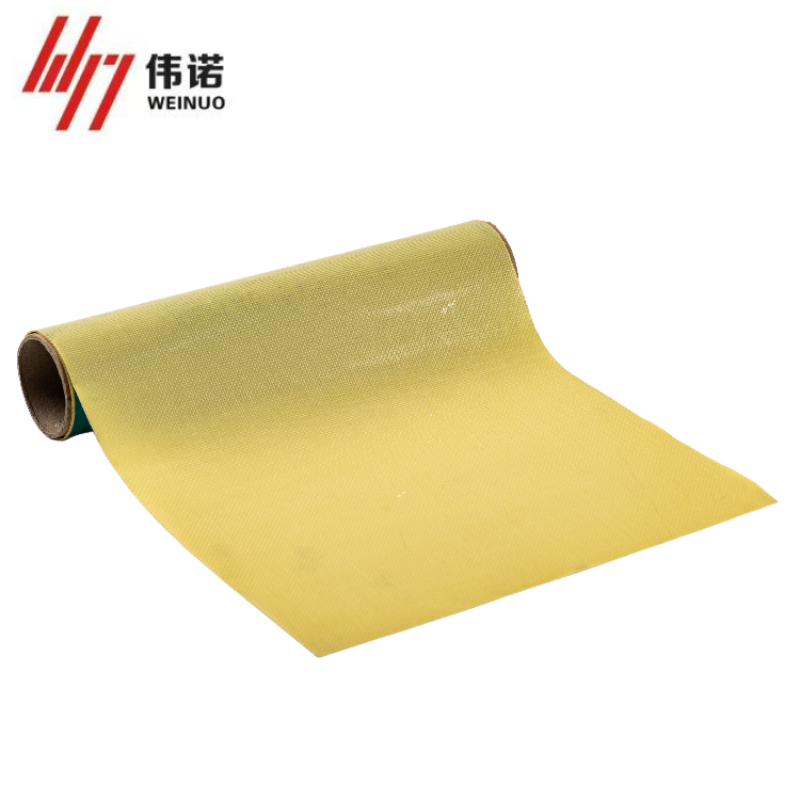

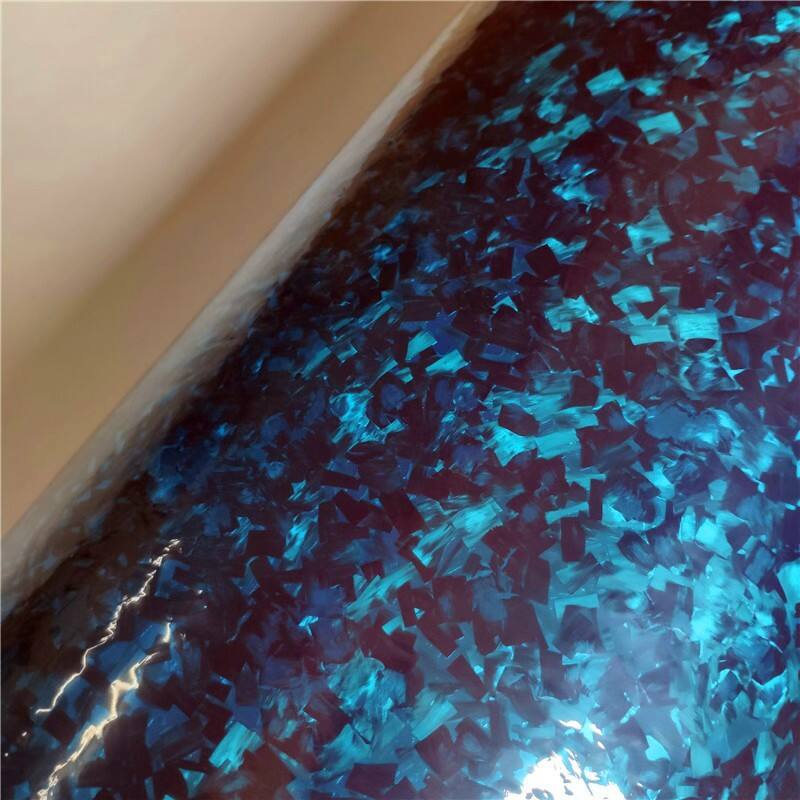

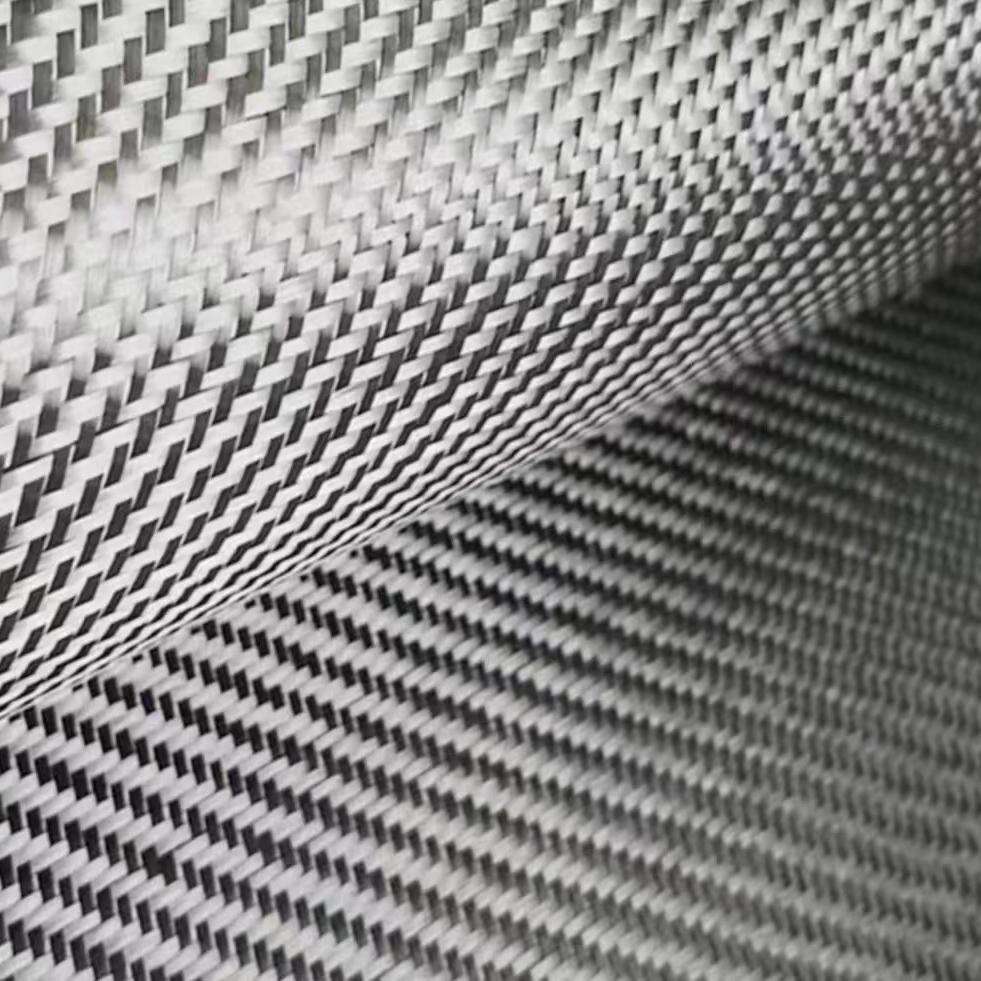

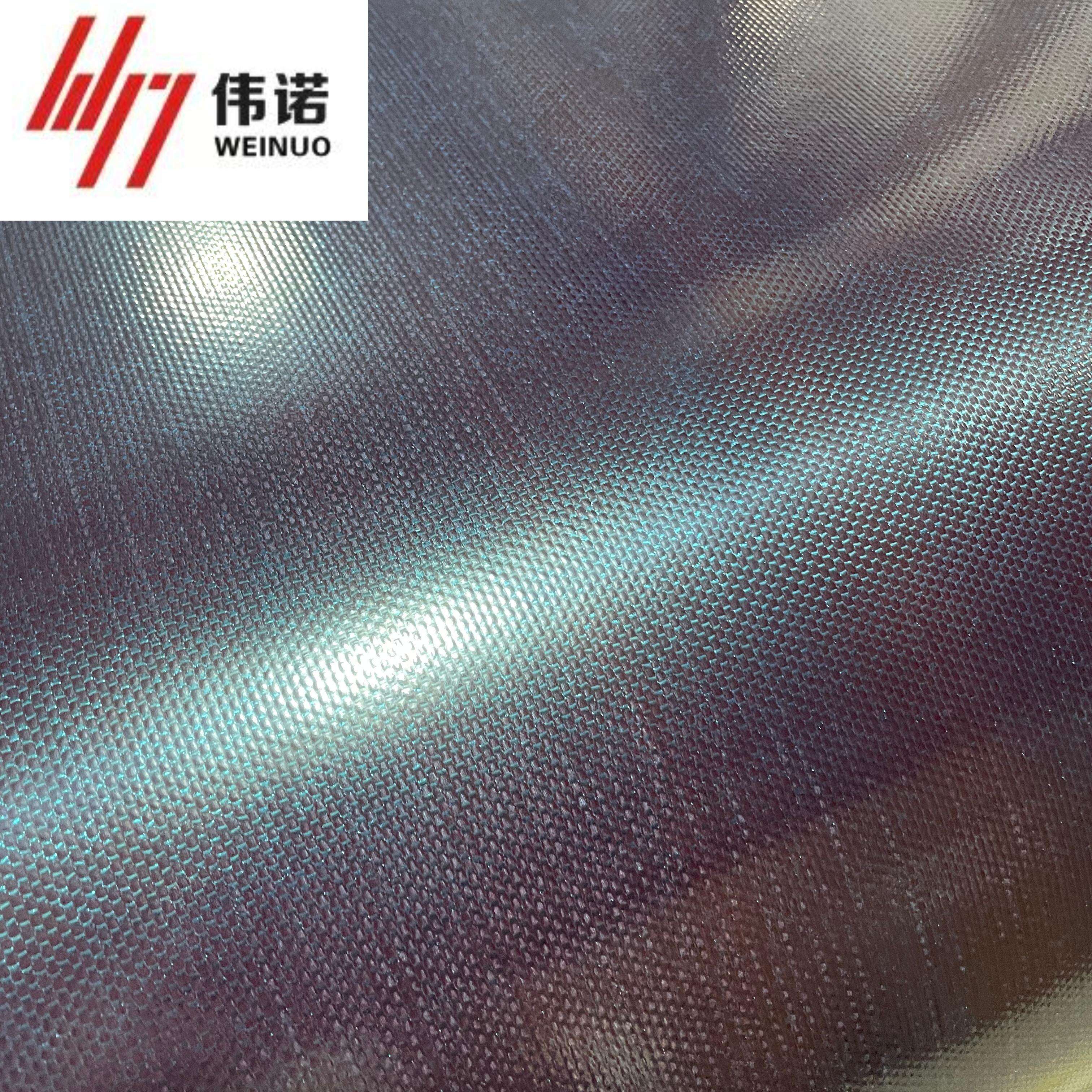

Prepreg carbon fiber types represent advanced composite materials that combine high-strength carbon fibers with pre-impregnated resin systems. These materials come in various forms, including unidirectional (UD), woven fabric, and multiaxial configurations. UD prepregs offer maximum strength in a single direction, making them ideal for applications requiring specific load-bearing capabilities. Woven fabric prepregs provide better handling characteristics and more balanced properties in multiple directions, while multiaxial variants allow for optimized fiber orientation to meet complex loading requirements. The resin systems used in these prepregs can be thermoset or thermoplastic, each offering distinct processing and performance characteristics. Thermoset prepregs typically cure at elevated temperatures, forming permanent cross-linked structures, while thermoplastic versions can be reprocessed. These materials find extensive applications in aerospace, automotive, sporting goods, and industrial sectors, where their exceptional strength-to-weight ratio, fatigue resistance, and design flexibility are particularly valuable. The manufacturing process involves precise control of fiber alignment, resin content, and cure parameters to achieve optimal mechanical properties.