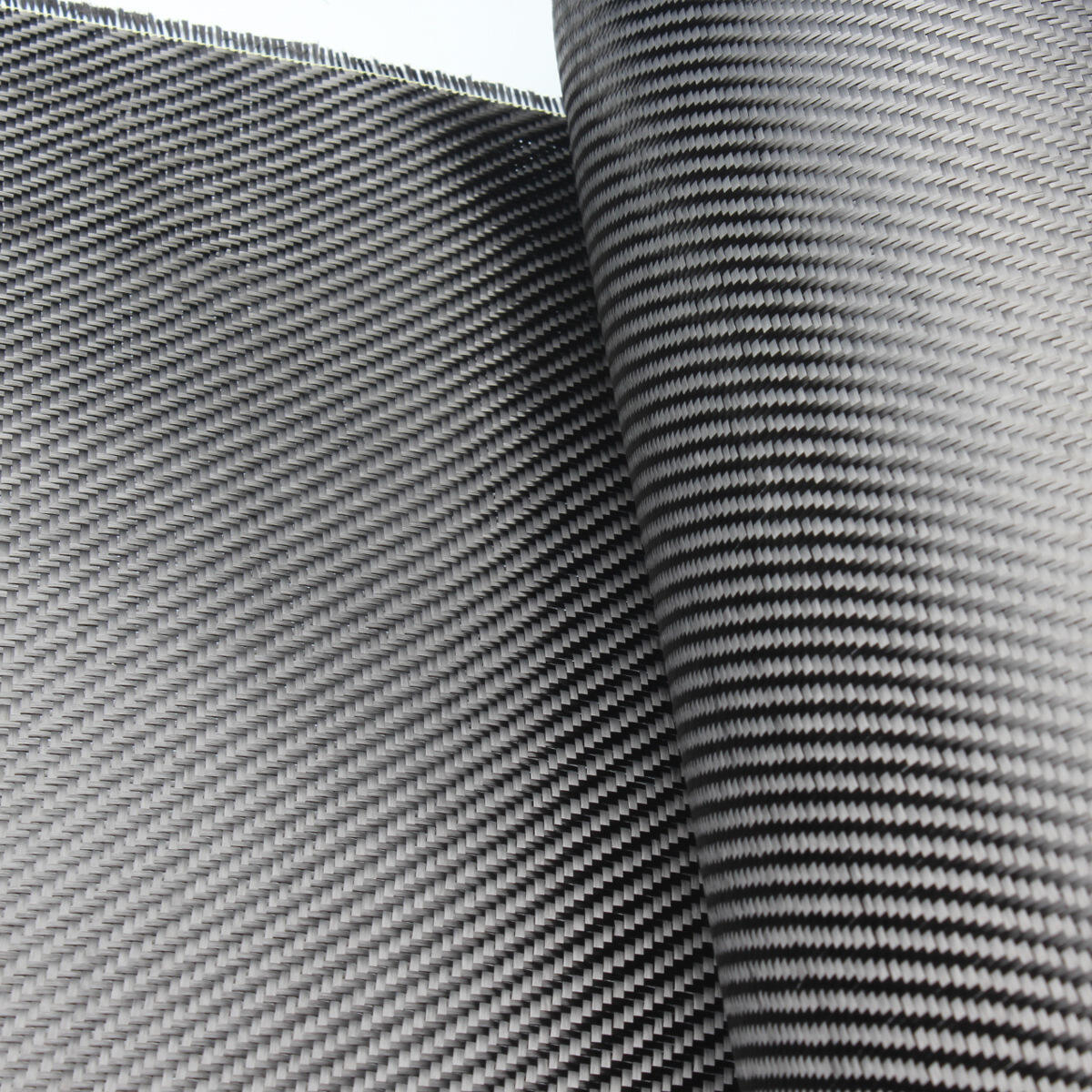

twill carbon fiber fabric

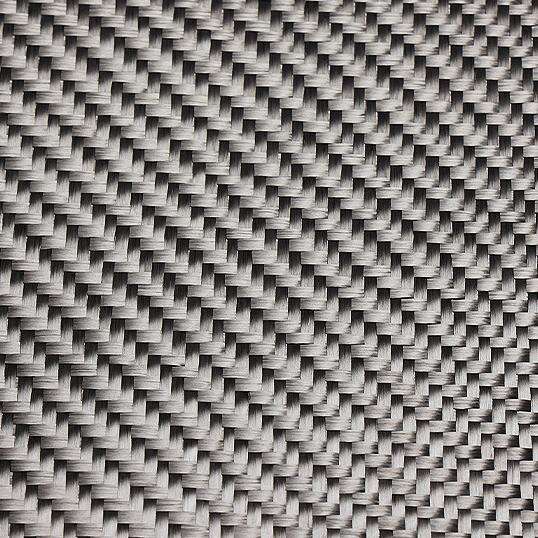

Twill carbon fiber fabric represents a sophisticated composite material characterized by its distinctive weave pattern, where carbon fibers are interlaced in a diagonal pattern creating a surface with a characteristic 2x2 or 4x4 weave. This advanced material combines exceptional strength with remarkable flexibility, making it a premier choice for high-performance applications. The fabric's unique weave pattern distributes stress more evenly across the material, providing superior draping qualities compared to plain weave alternatives. The material exhibits outstanding mechanical properties, including high tensile strength, excellent fatigue resistance, and exceptional dimensional stability. When combined with appropriate resin systems, twill carbon fiber fabric forms a robust composite structure that maintains its integrity under demanding conditions. The material's versatility extends across various industries, from aerospace and automotive applications to sporting goods and architectural elements. Its aesthetic appeal, characterized by a distinctive diagonal pattern, makes it particularly popular in visible applications where both performance and appearance matter. The fabric's relatively low weight-to-strength ratio, combined with its resistance to environmental factors and thermal stability, positions it as an ideal material for applications requiring high performance and reliability. Modern manufacturing techniques have made twill carbon fiber fabric increasingly accessible while maintaining its premium quality and performance characteristics.