forged carbon fiber parts for sale

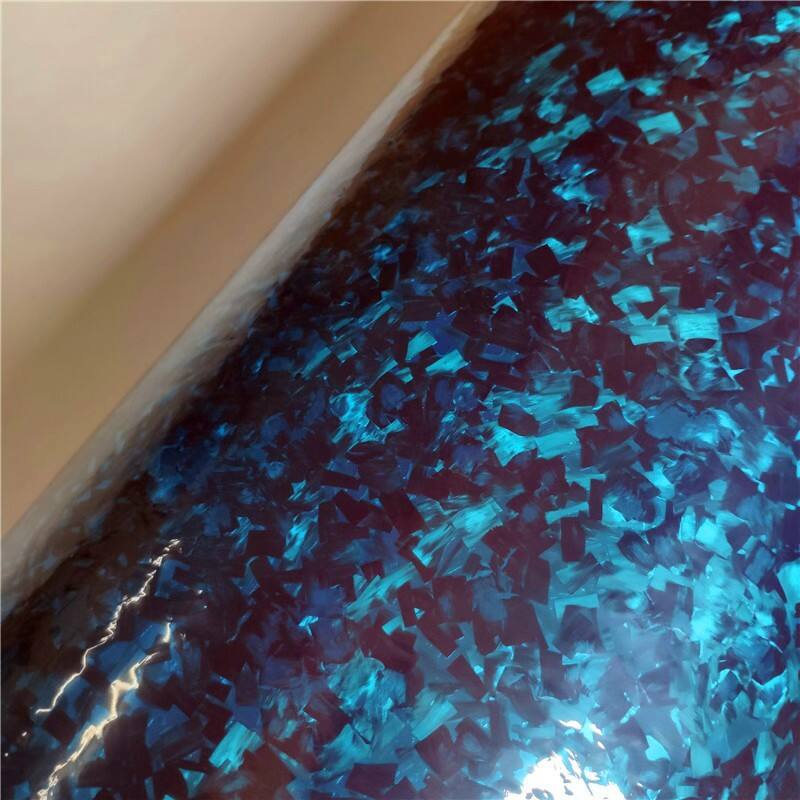

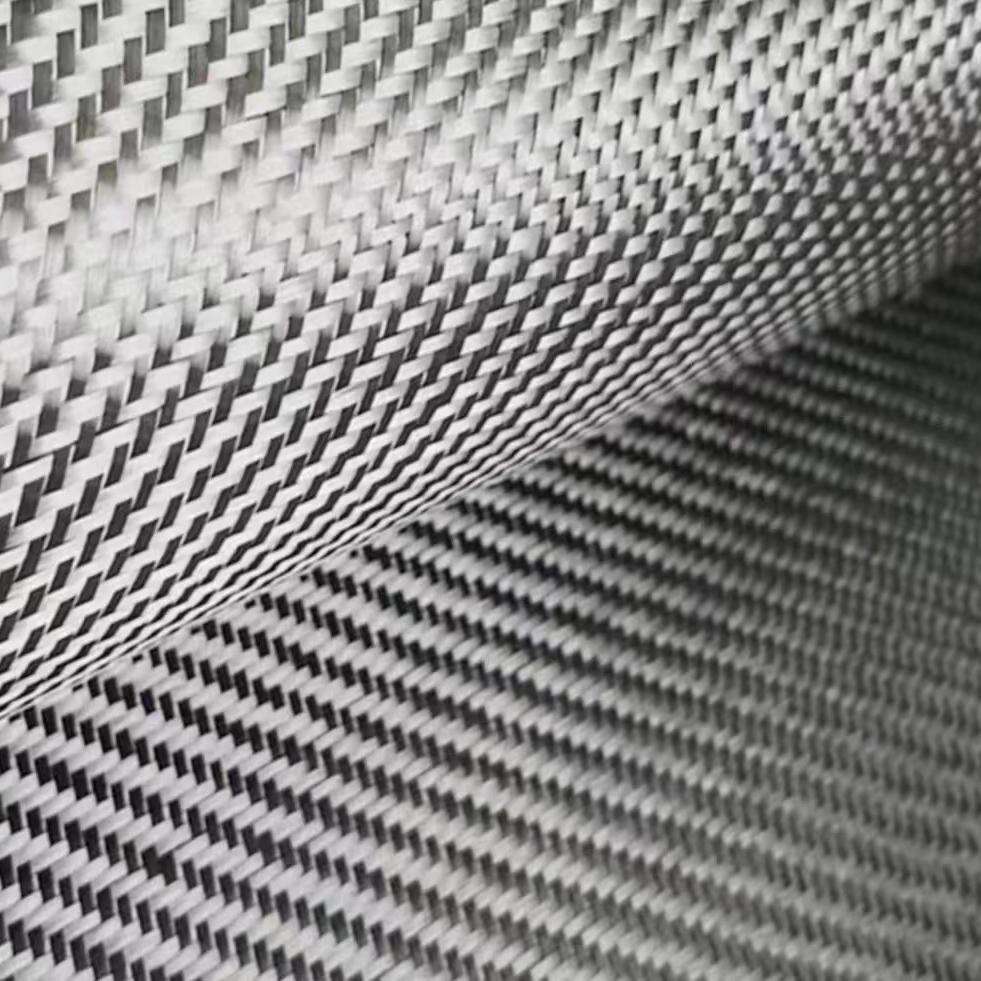

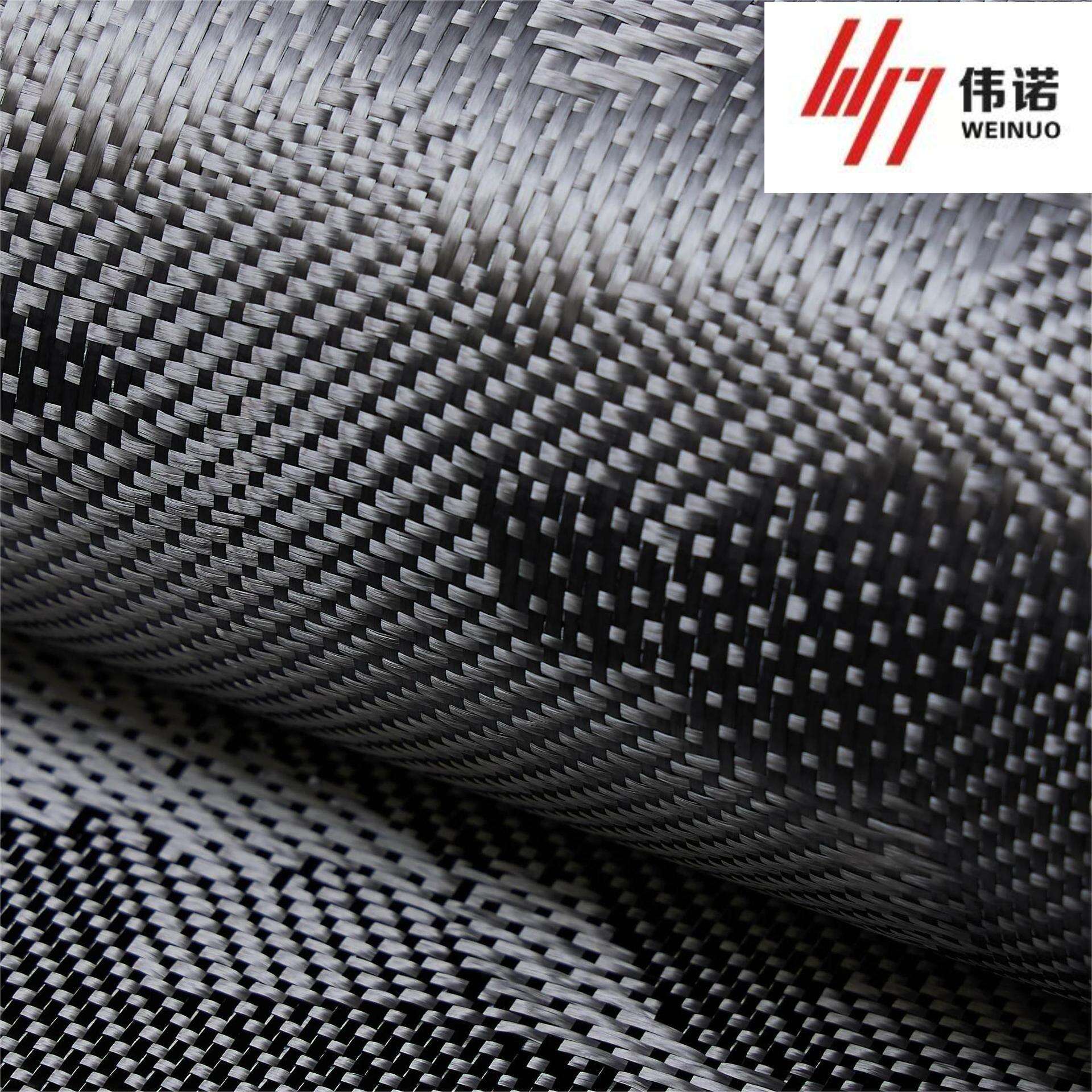

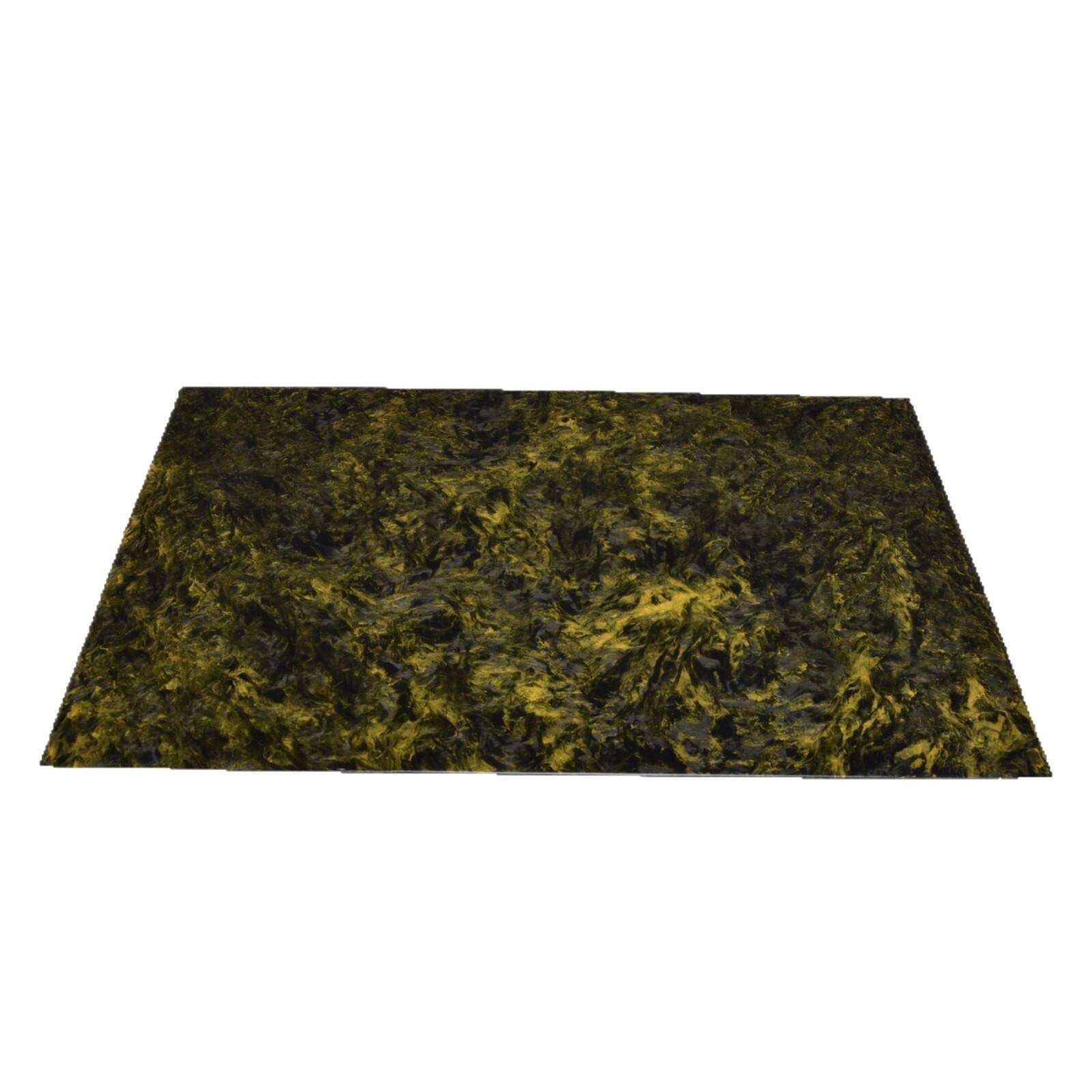

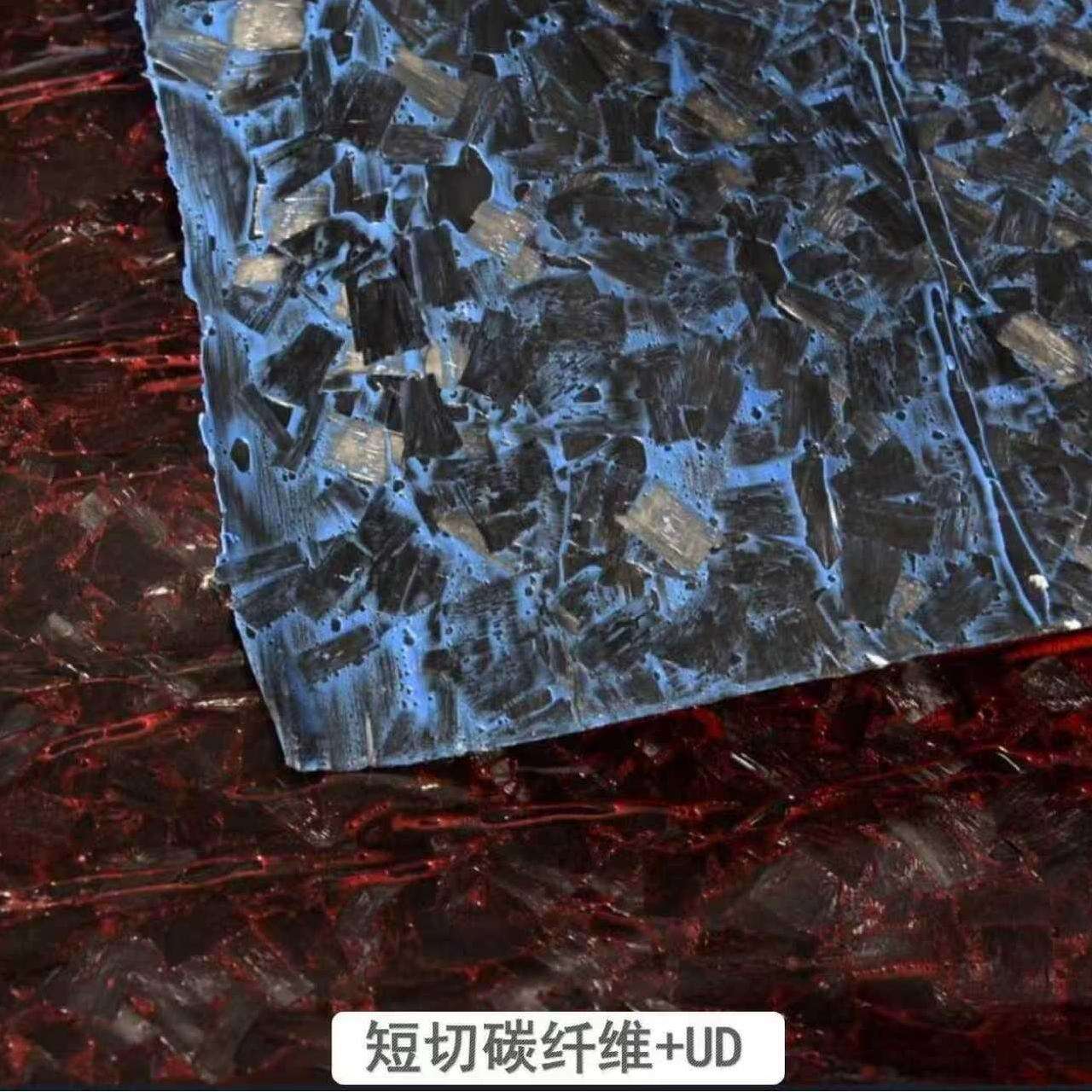

Forged carbon fiber parts represent a revolutionary advancement in automotive and industrial manufacturing, offering an exceptional blend of strength, lightweight construction, and aesthetic appeal. These components are created through an innovative process that combines chopped carbon fiber with resin under extreme pressure and heat, resulting in a unique material that surpasses traditional carbon fiber in many aspects. The manufacturing process allows for complex geometries and shapes that would be difficult or impossible to achieve with conventional layered carbon fiber. Each forged carbon fiber part exhibits a distinctive marbled pattern, making every piece uniquely beautiful while maintaining superior structural integrity. These parts are extensively used in high-performance vehicles, aerospace applications, and premium consumer products where weight reduction and structural strength are paramount. The forged carbon fiber parts available for sale undergo rigorous quality control measures, ensuring consistency in both appearance and performance. They are engineered to meet or exceed OEM specifications, offering direct bolt-on compatibility for various applications. The parts are finished with a UV-resistant clear coat to maintain their appearance and protect against environmental factors, ensuring long-term durability.