prepreg forged carbon fiber

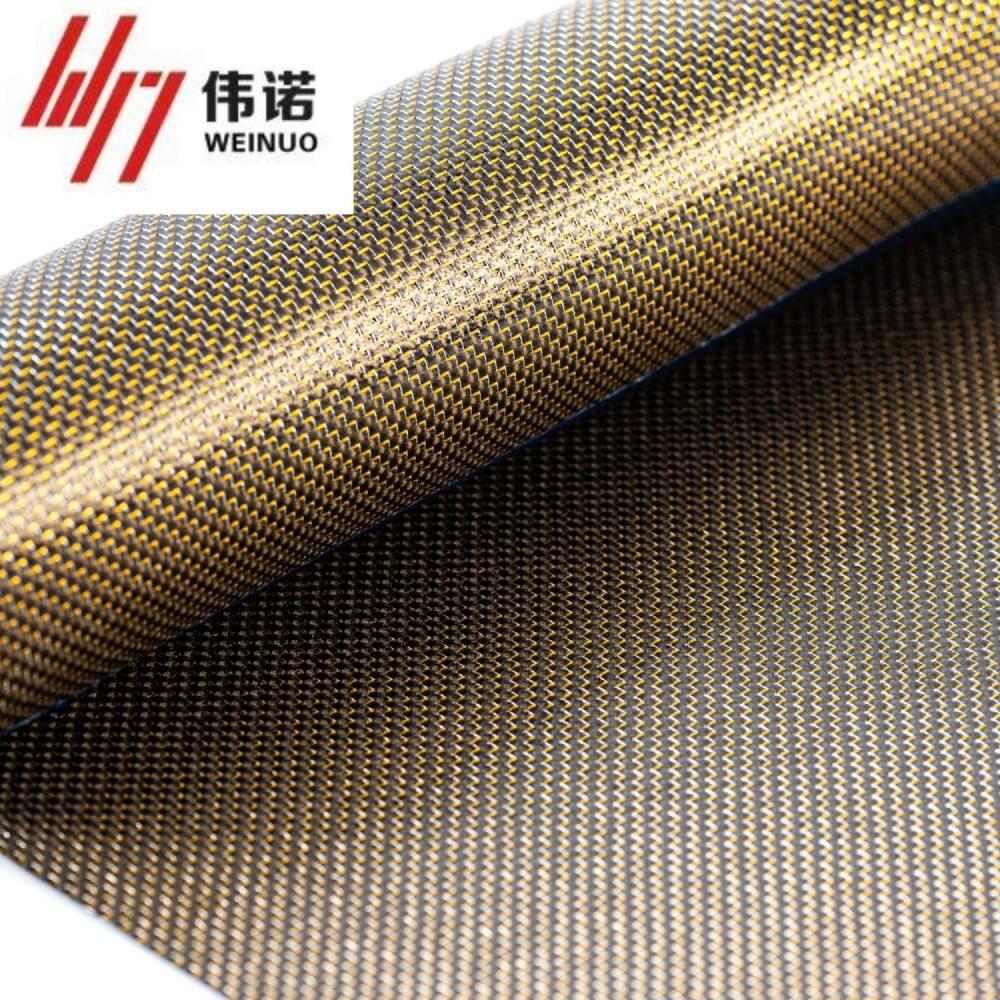

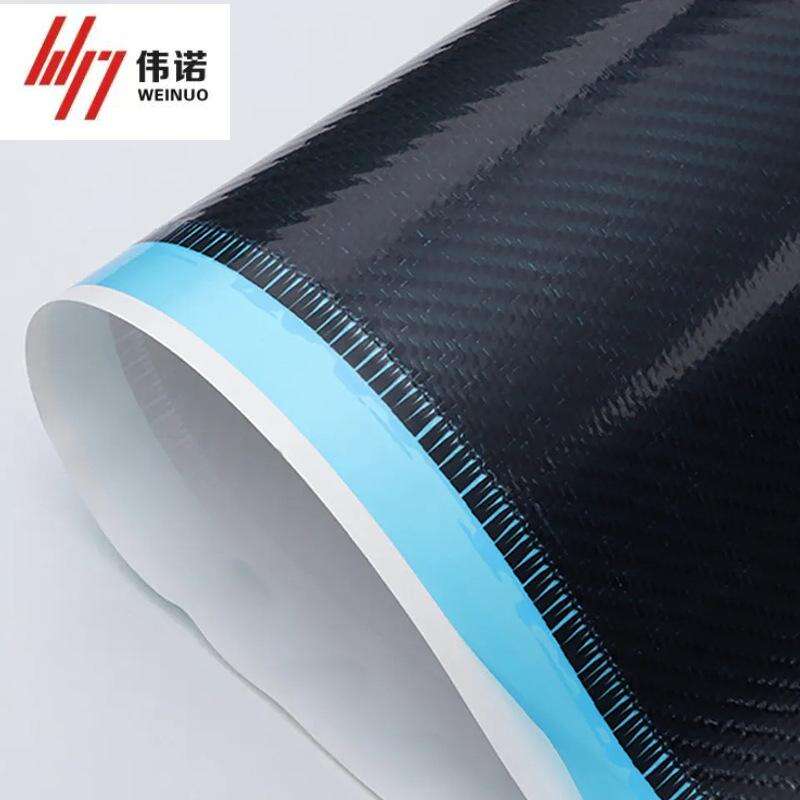

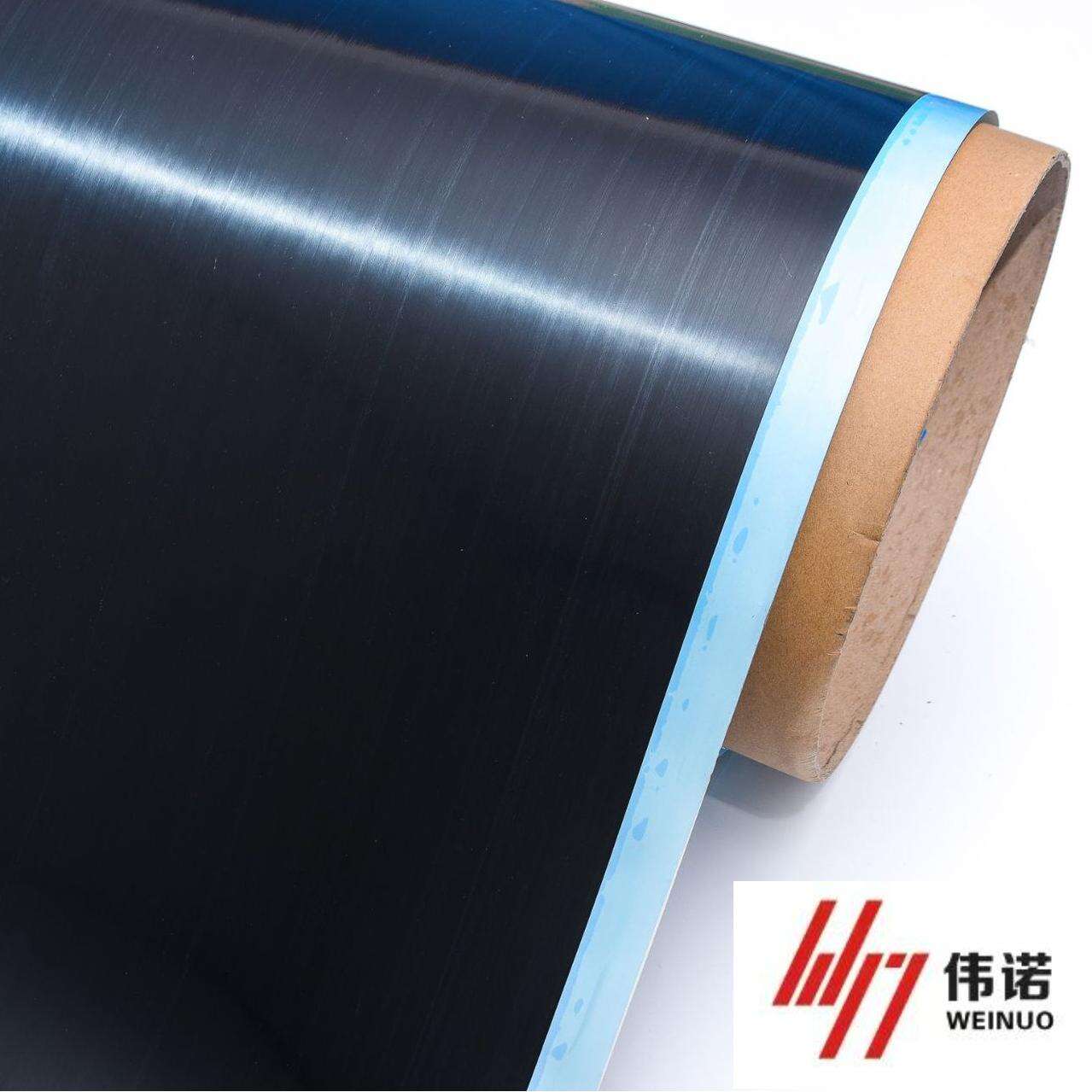

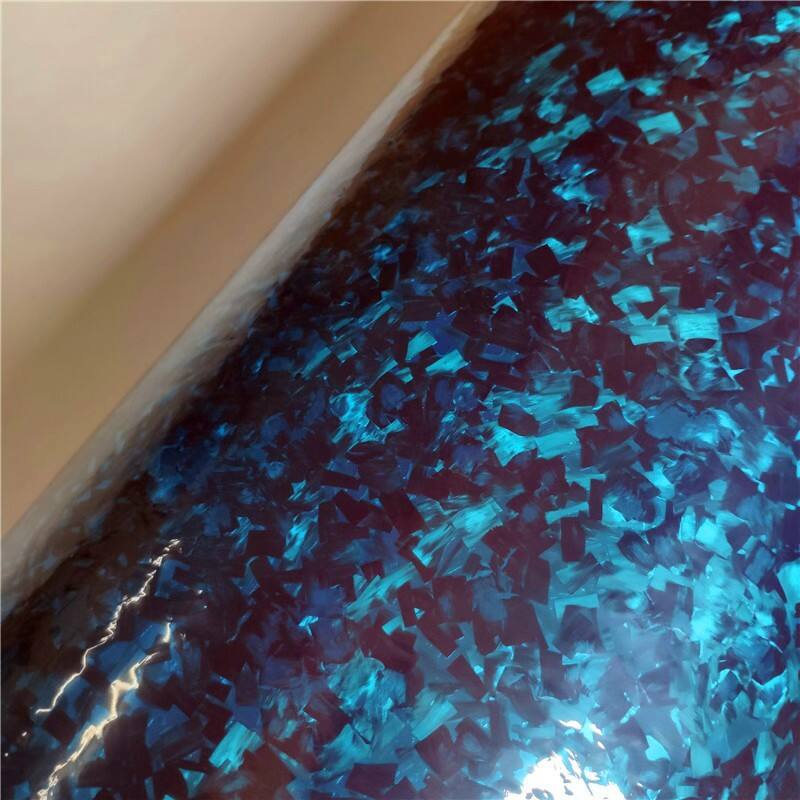

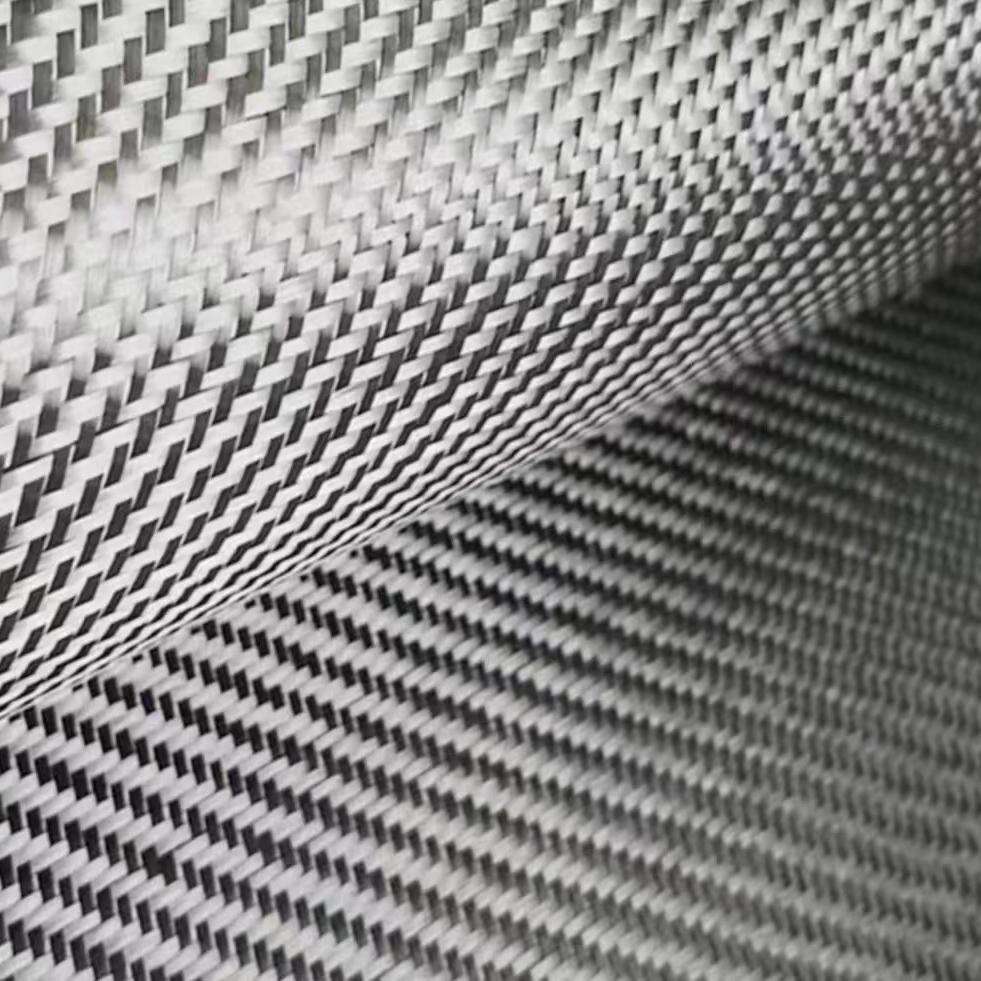

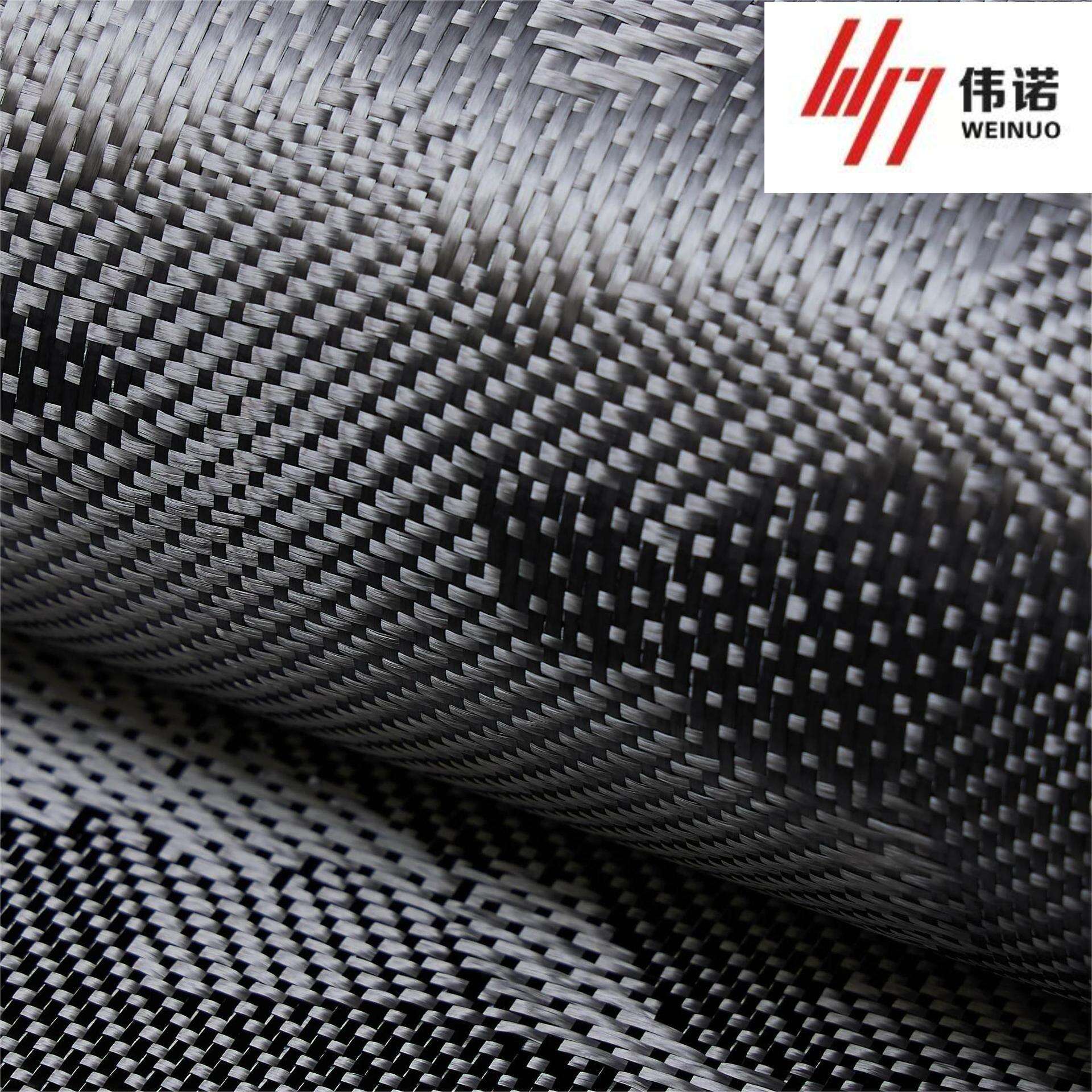

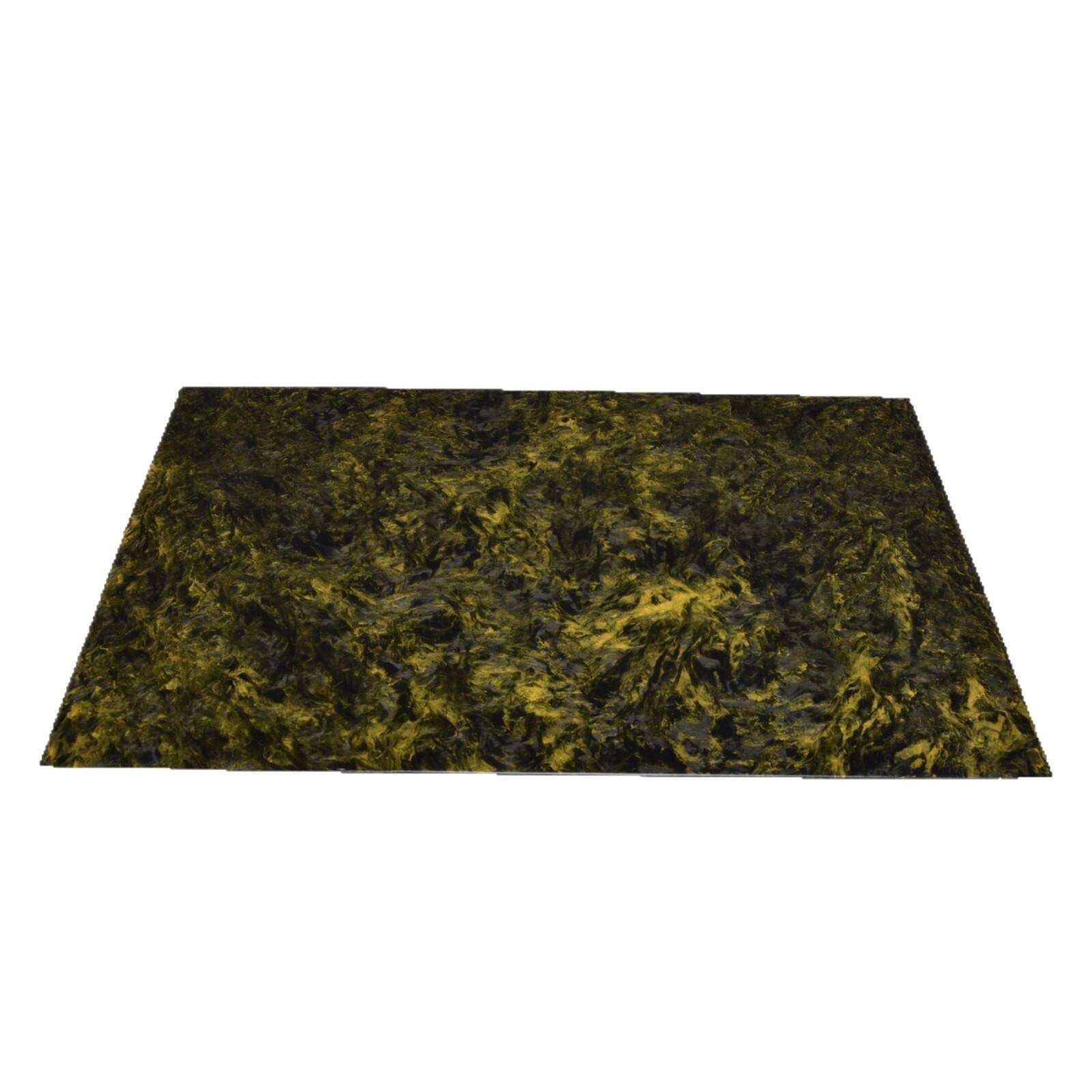

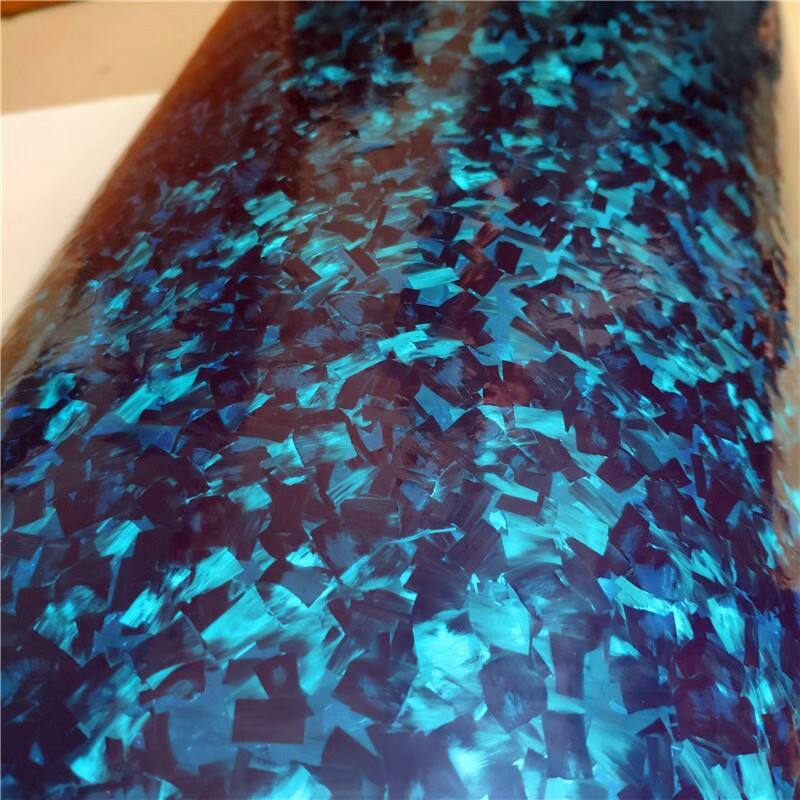

Prepreg forged carbon fiber represents a groundbreaking advancement in composite materials technology, combining the strength of traditional carbon fiber with innovative manufacturing processes. This premium material consists of pre-impregnated carbon fiber sheets that undergo a specialized forging process under precise temperature and pressure conditions. The result is a unique, randomized fiber pattern that distinguishes it from traditional woven carbon fiber materials. During manufacture, the carbon fibers are precisely aligned and distributed within a thermosetting resin matrix, creating a material that offers exceptional structural integrity and dimensional stability. The prepreg process ensures consistent resin content and fiber distribution throughout the material, leading to superior mechanical properties and reliability in final applications. This advanced composite material finds extensive use in automotive components, aerospace structures, high-performance sporting goods, and luxury consumer products. The material's ability to be molded into complex shapes while maintaining its structural properties makes it particularly valuable for applications requiring both strength and design flexibility. Its distinctive aesthetic appearance, characterized by a marbled pattern, adds a premium visual element that sets it apart from conventional carbon fiber products.