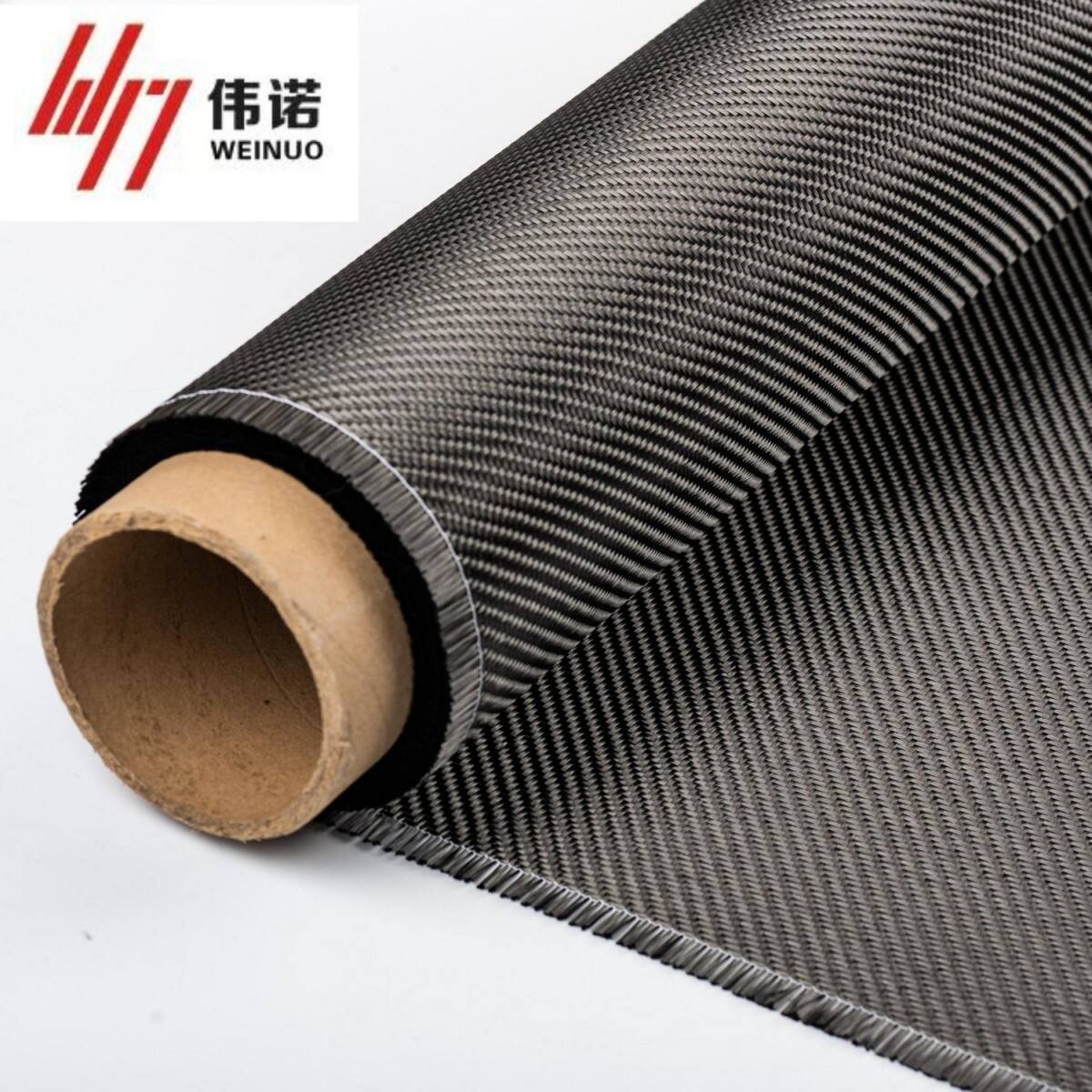

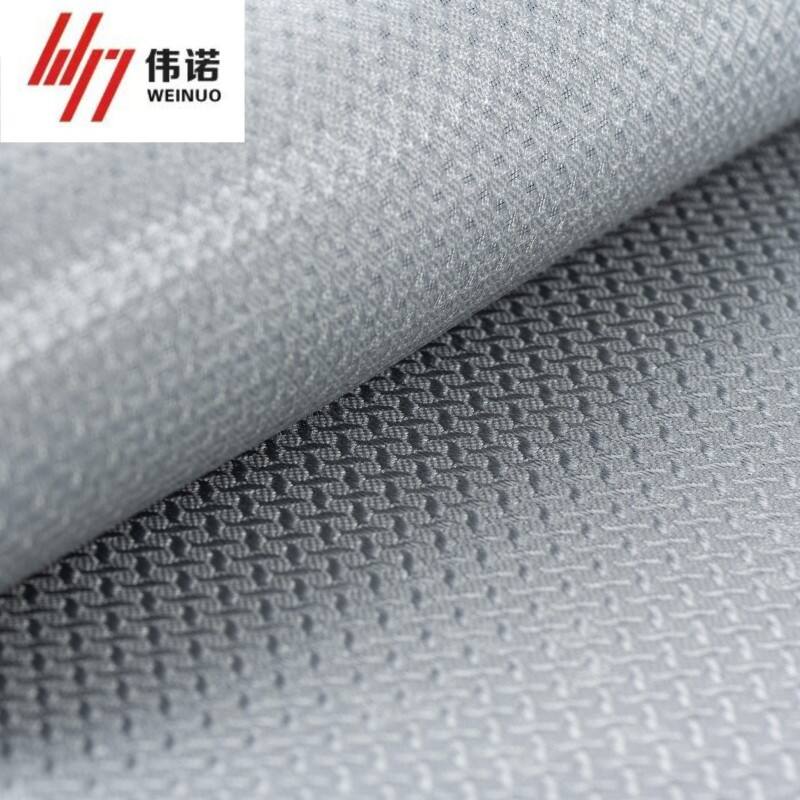

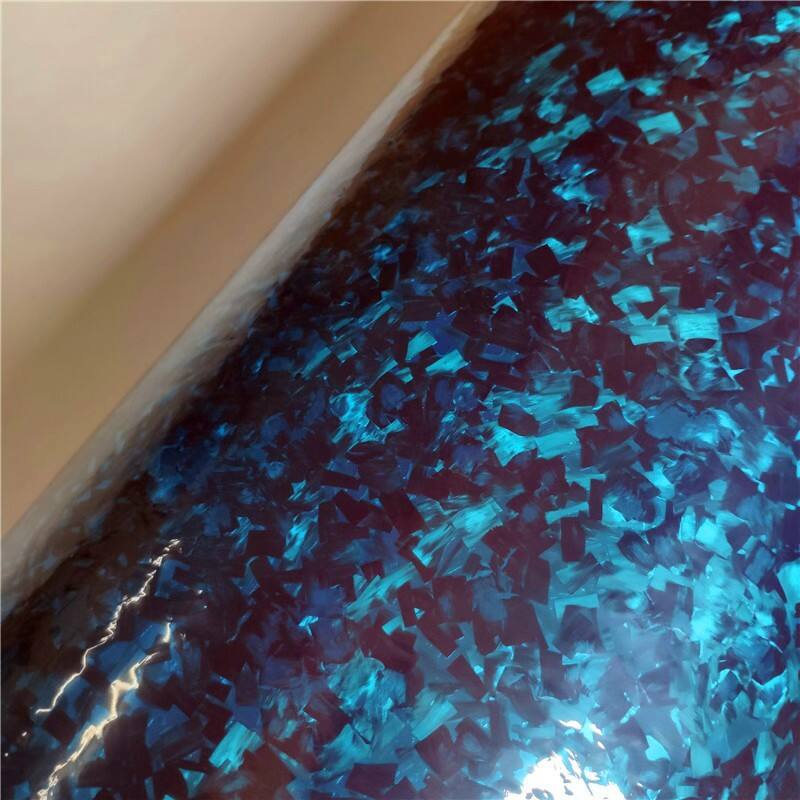

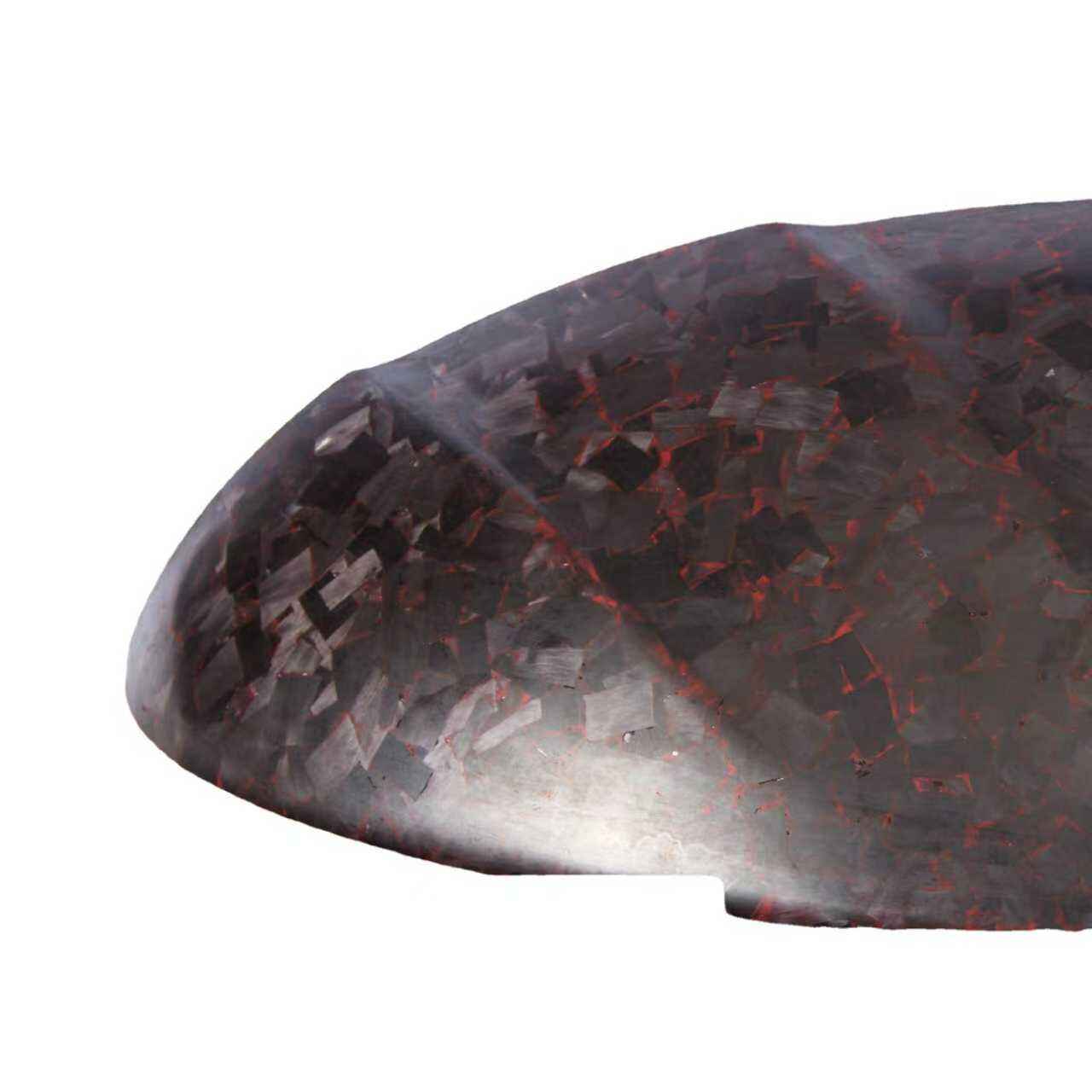

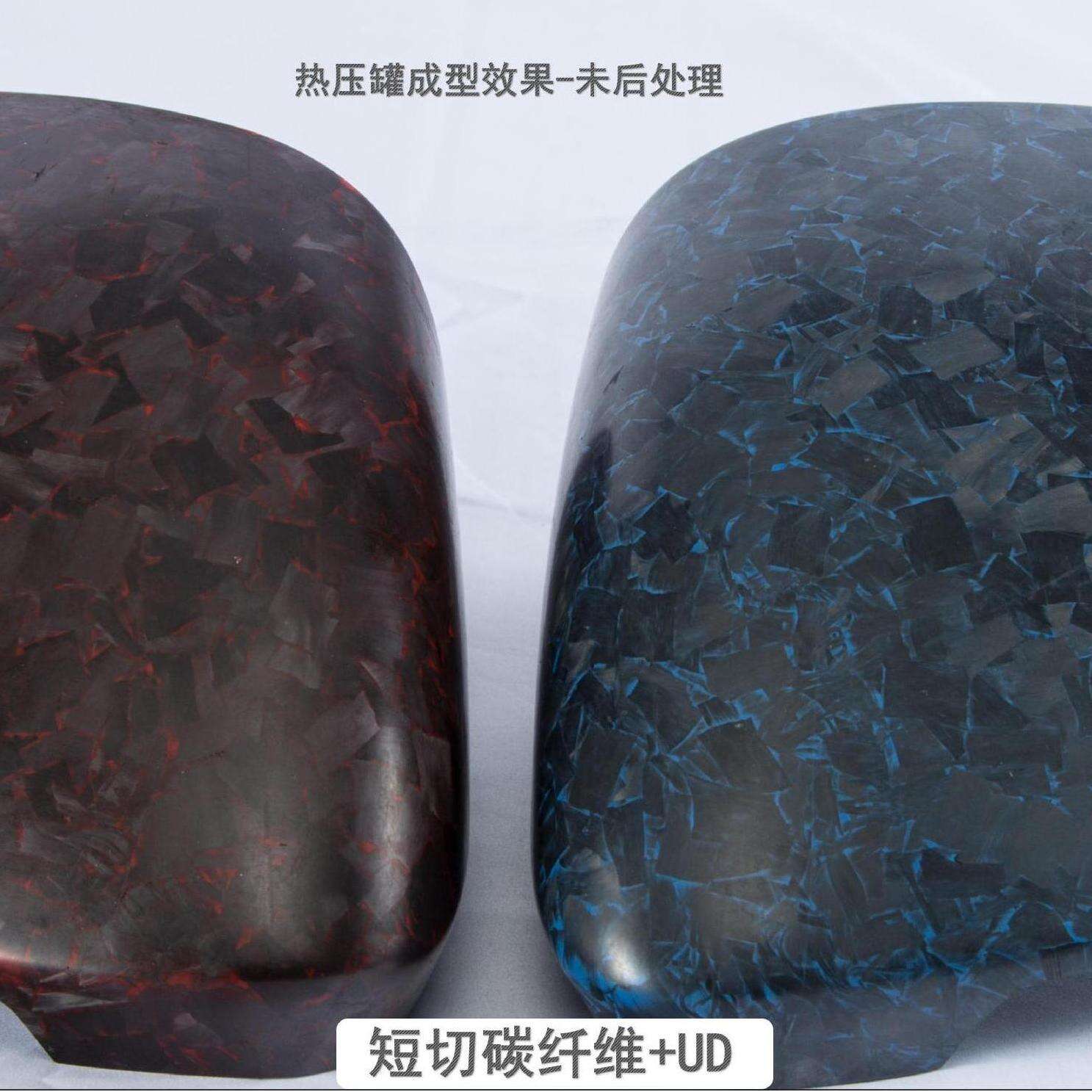

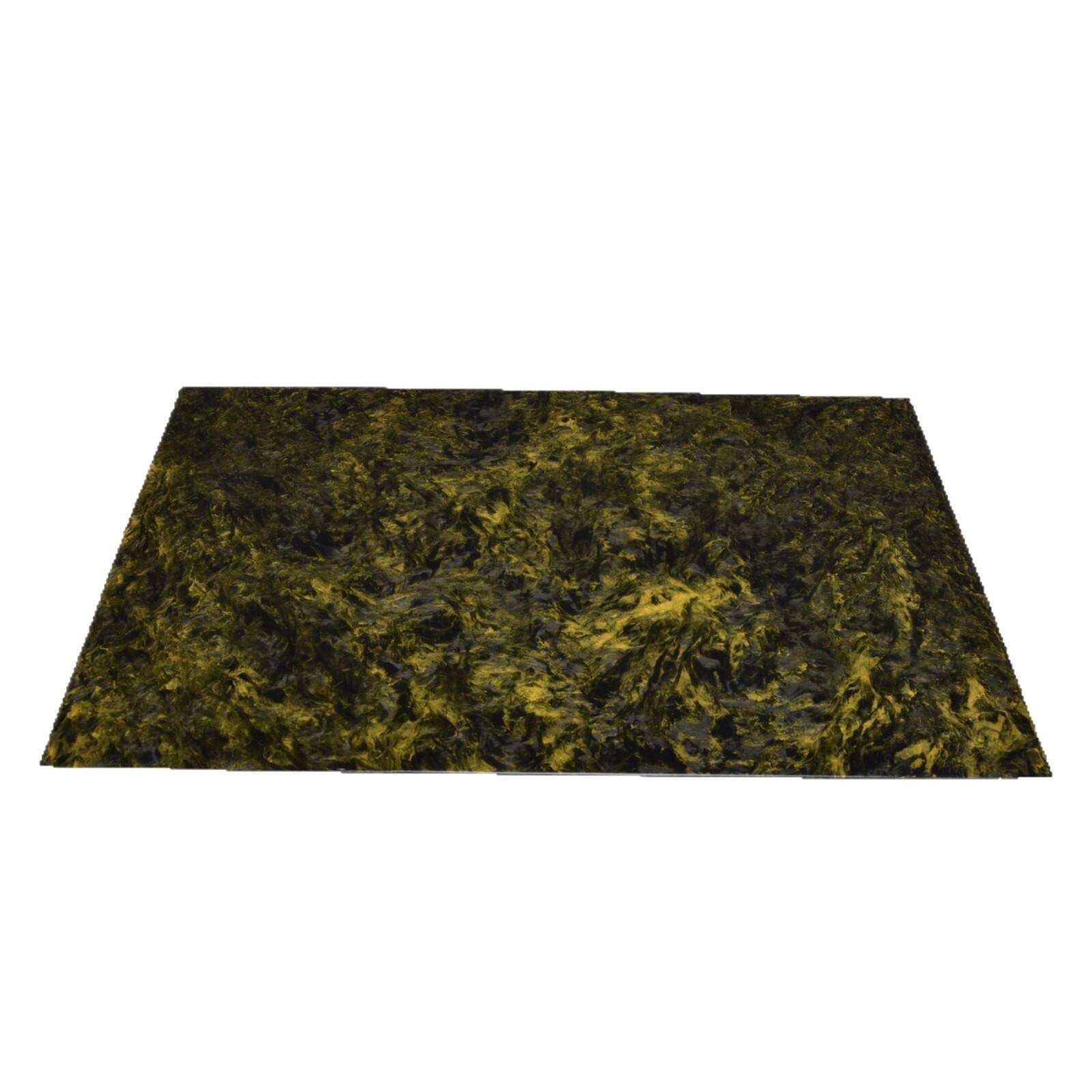

forged carbon fiber material

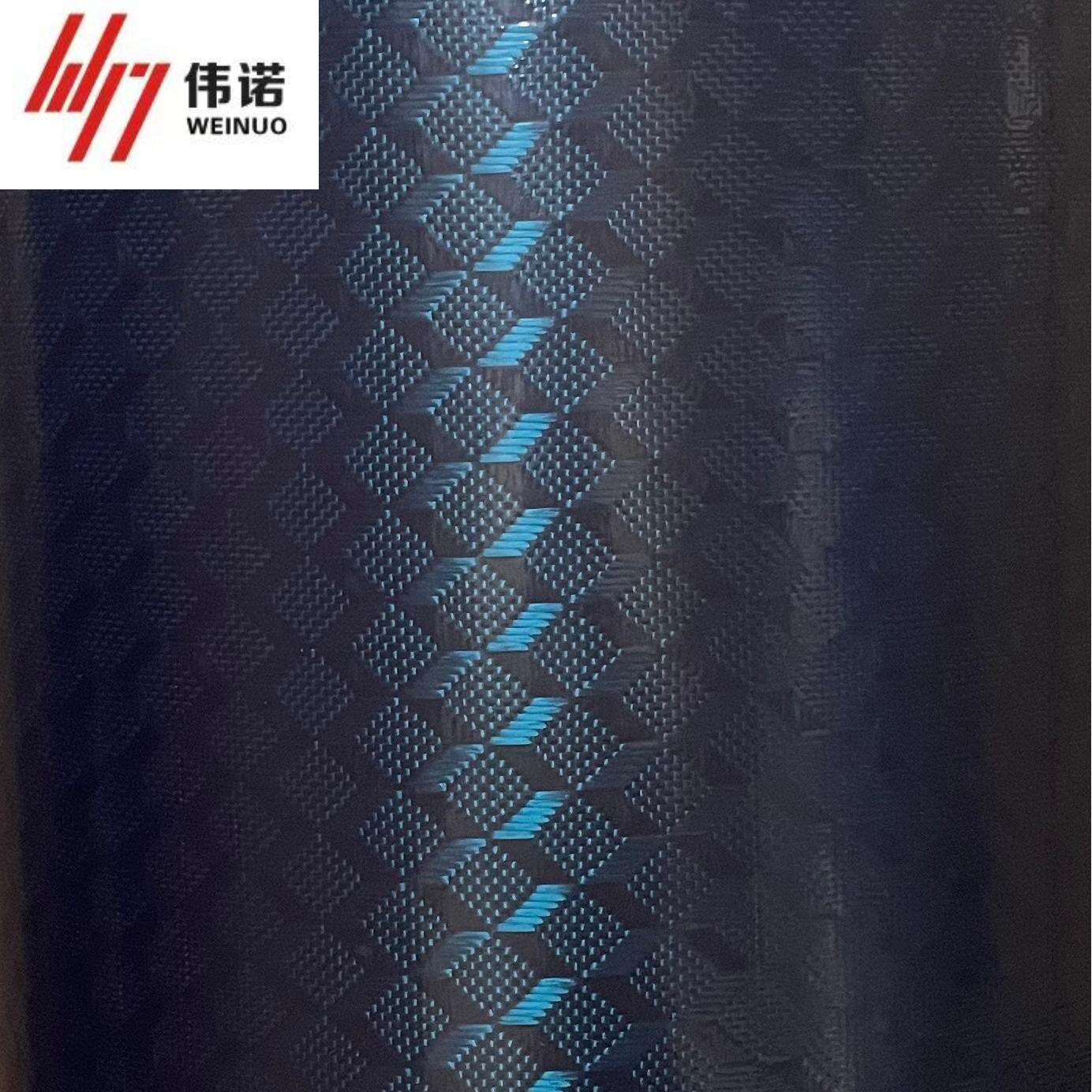

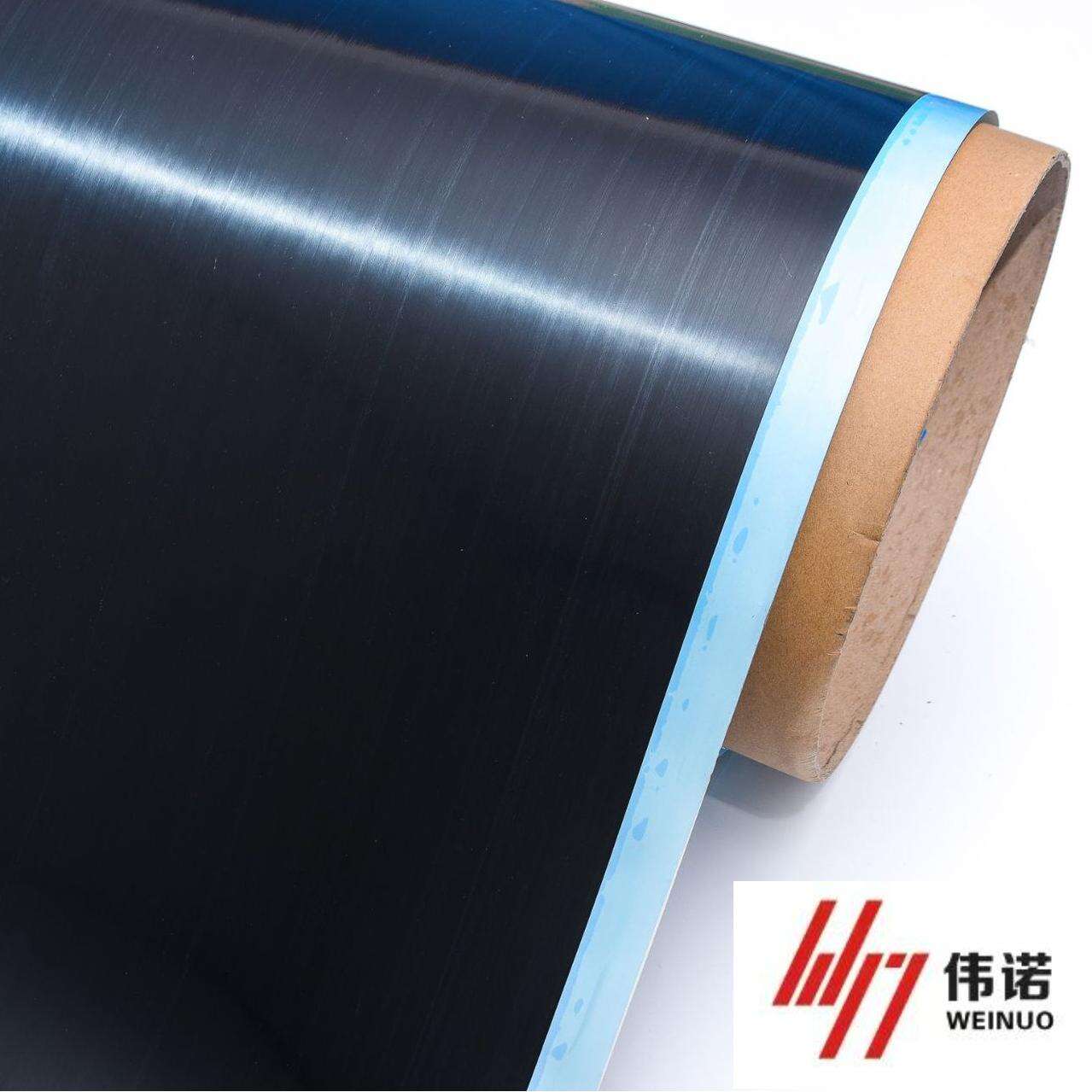

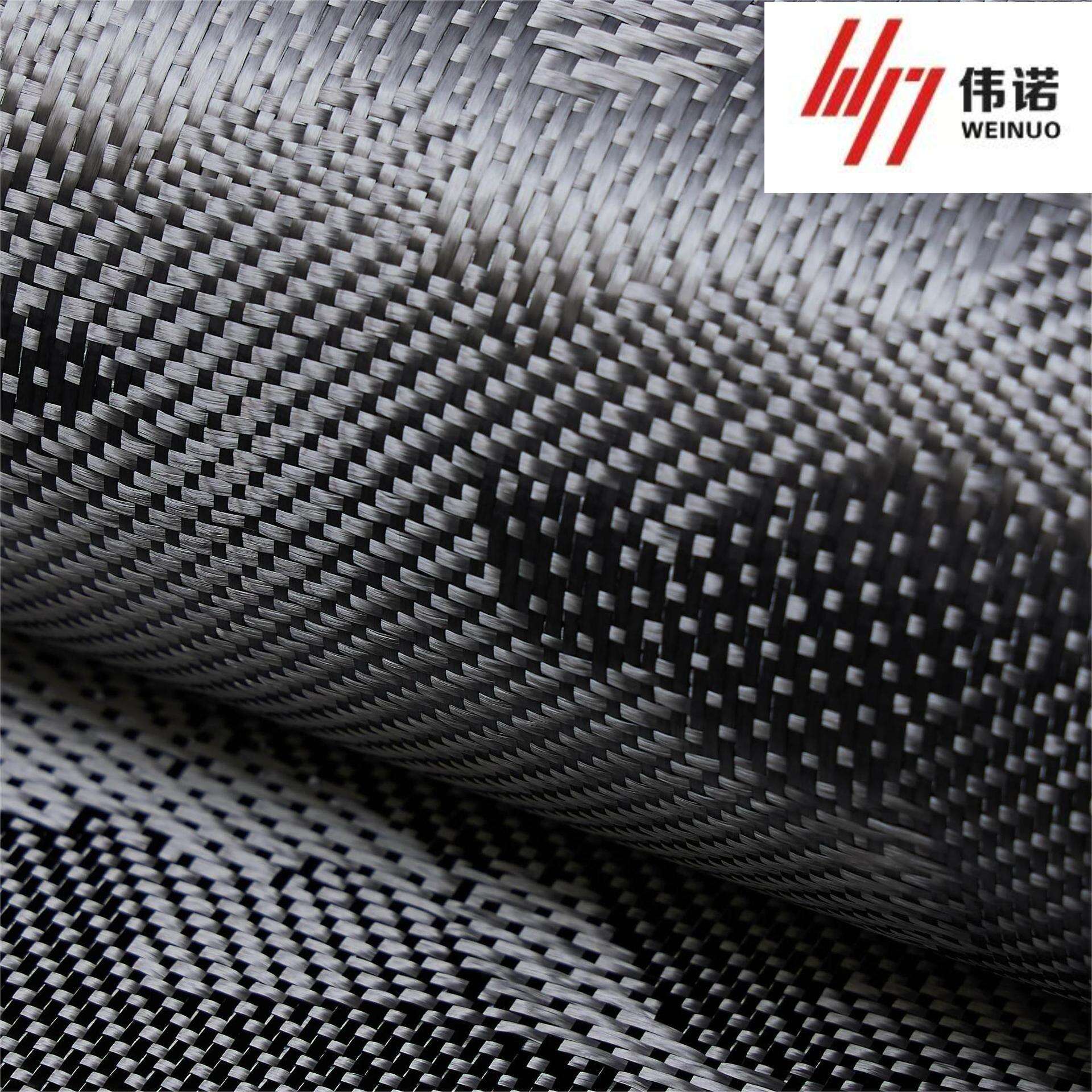

Forged carbon fiber represents a revolutionary advancement in composite materials technology, offering a unique combination of strength, lightweight properties, and aesthetic appeal. This innovative material is created through a specialized manufacturing process where short carbon fiber strands are combined with resin under high pressure and temperature, resulting in a random, marbled pattern that distinguishes it from traditional woven carbon fiber. The process allows for complex shapes and geometries that would be difficult or impossible to achieve with conventional carbon fiber layups. The material exhibits exceptional mechanical properties, including superior strength-to-weight ratio, enhanced impact resistance, and remarkable durability. Its versatility makes it ideal for various applications across automotive, aerospace, sporting goods, and luxury products industries. The manufacturing process is more efficient than traditional carbon fiber production, allowing for faster cycle times and reduced waste. Additionally, the random fiber orientation provides more consistent structural properties in all directions, unlike traditional carbon fiber's directional strength characteristics. This material has gained significant traction in high-performance applications where both structural integrity and aesthetic appeal are crucial considerations.