forged carbon fiber parts manufacturer

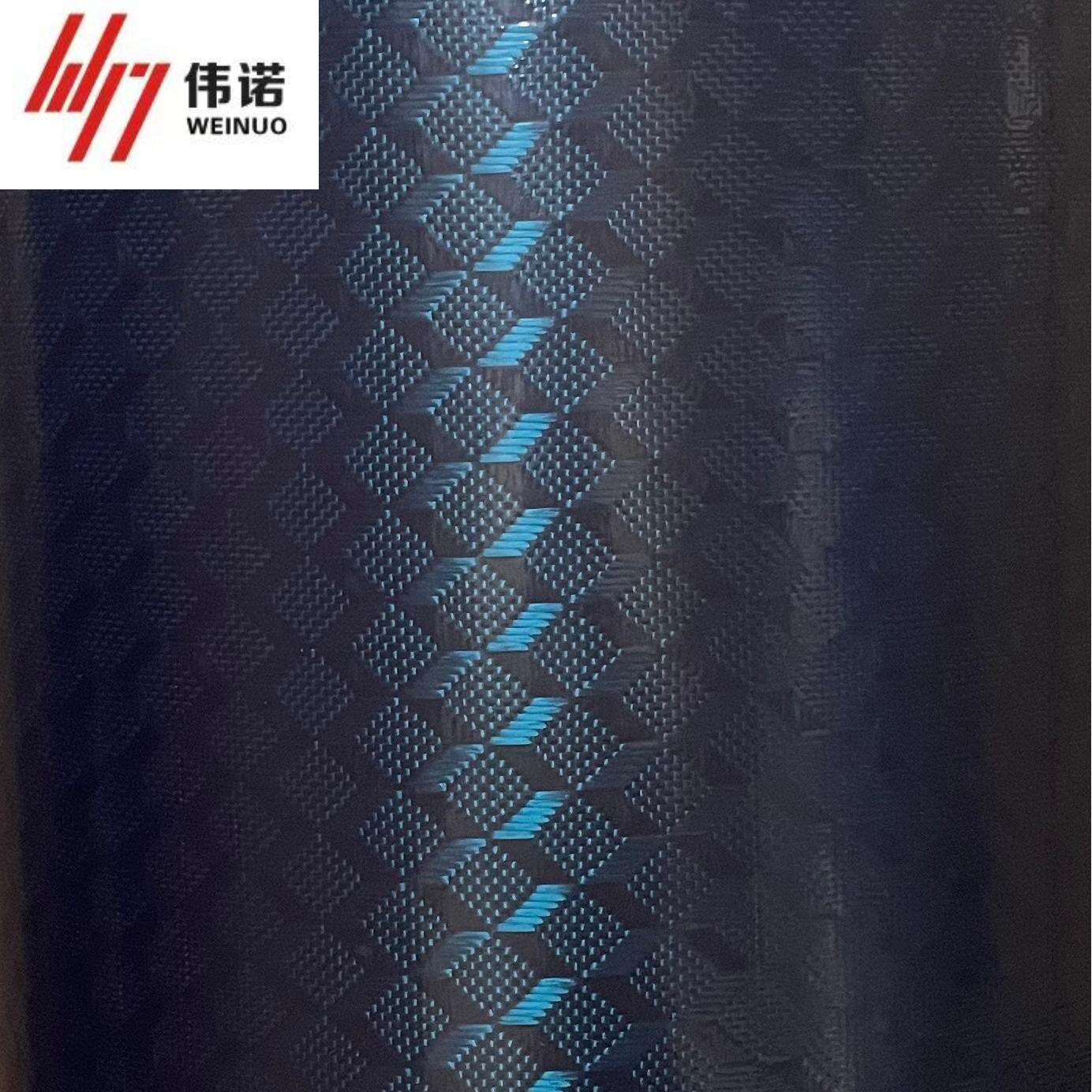

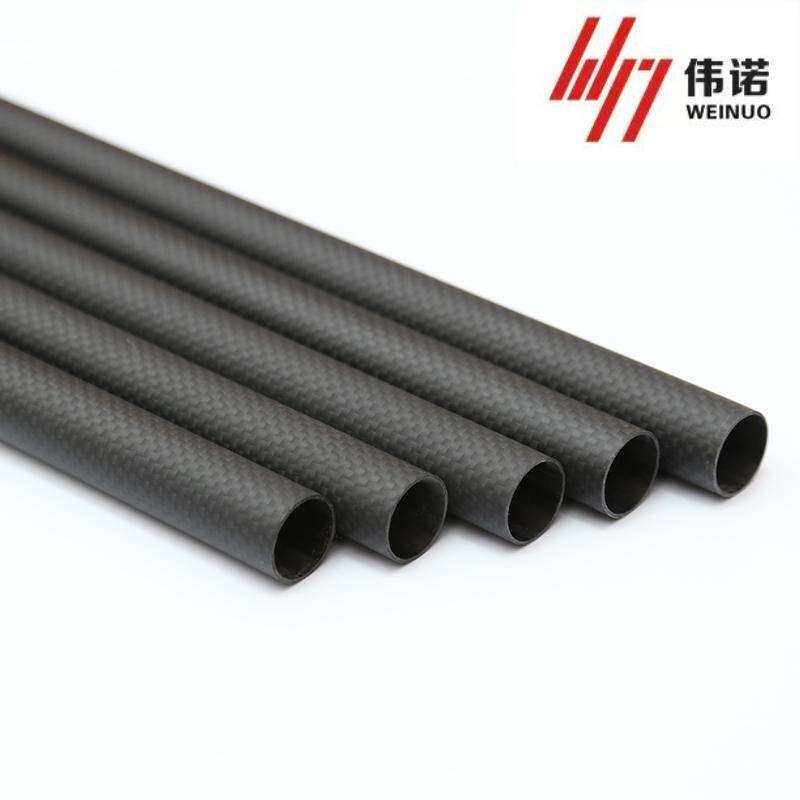

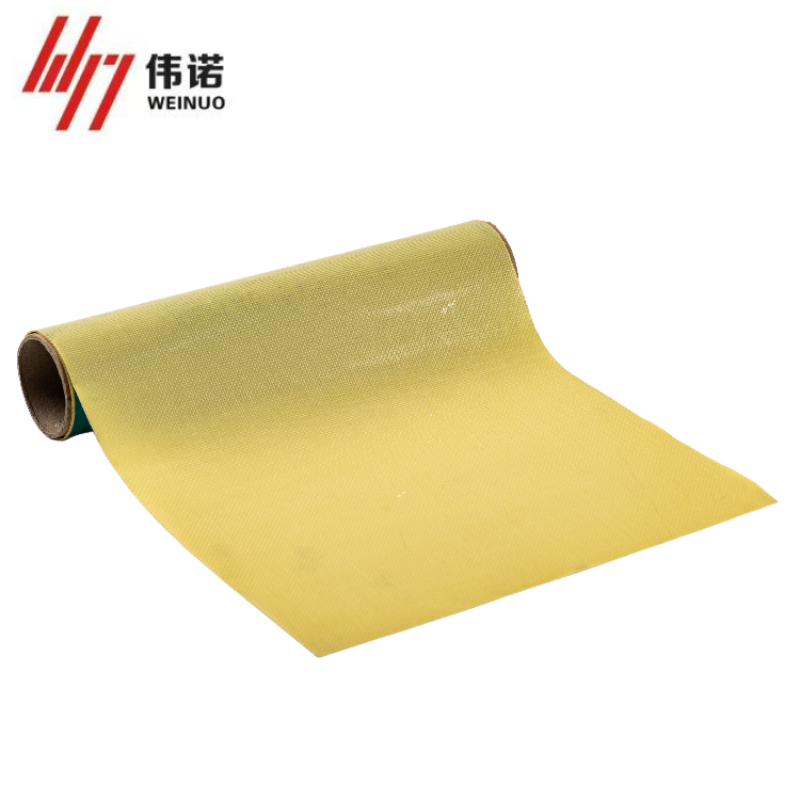

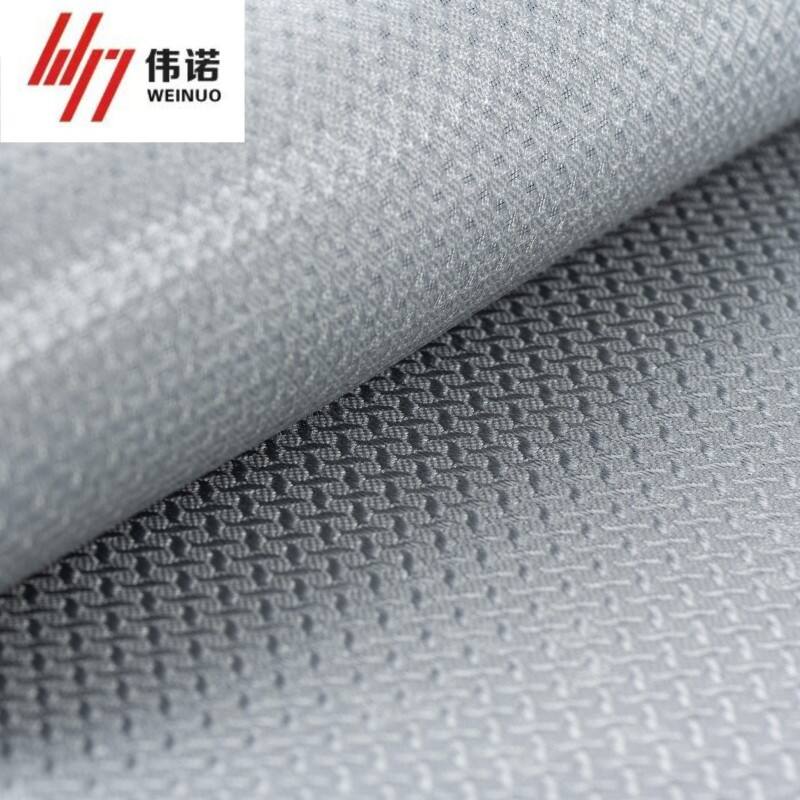

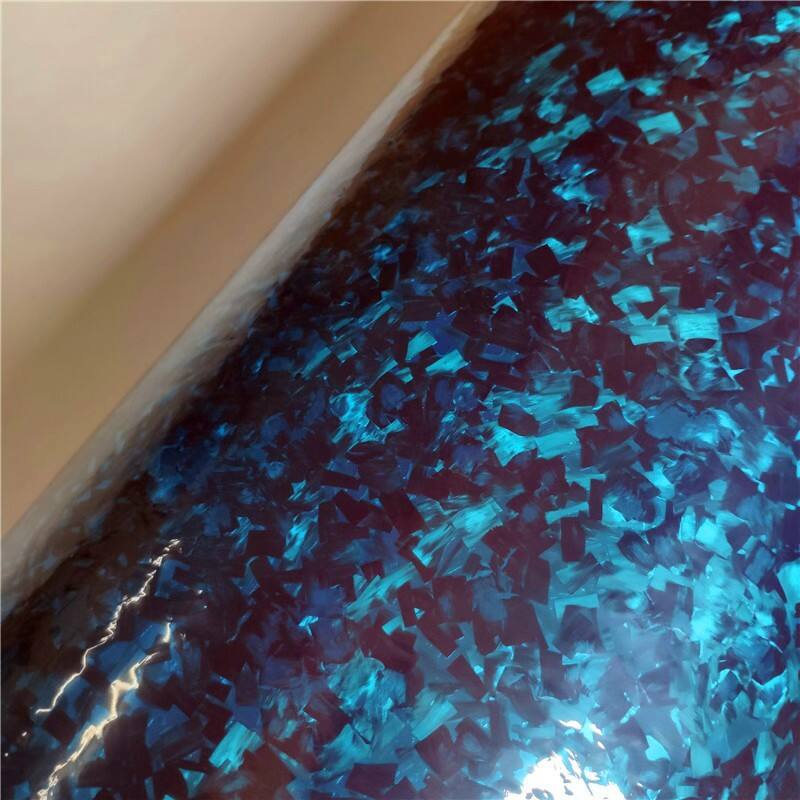

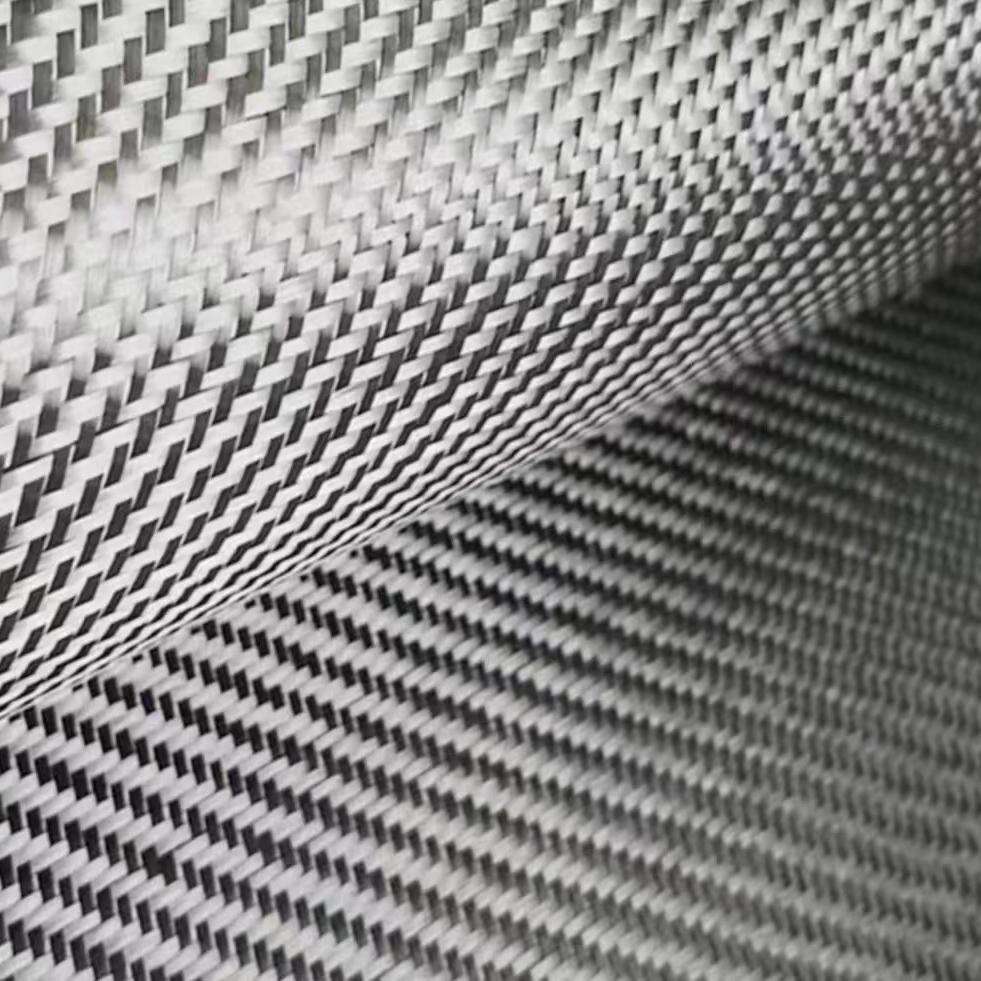

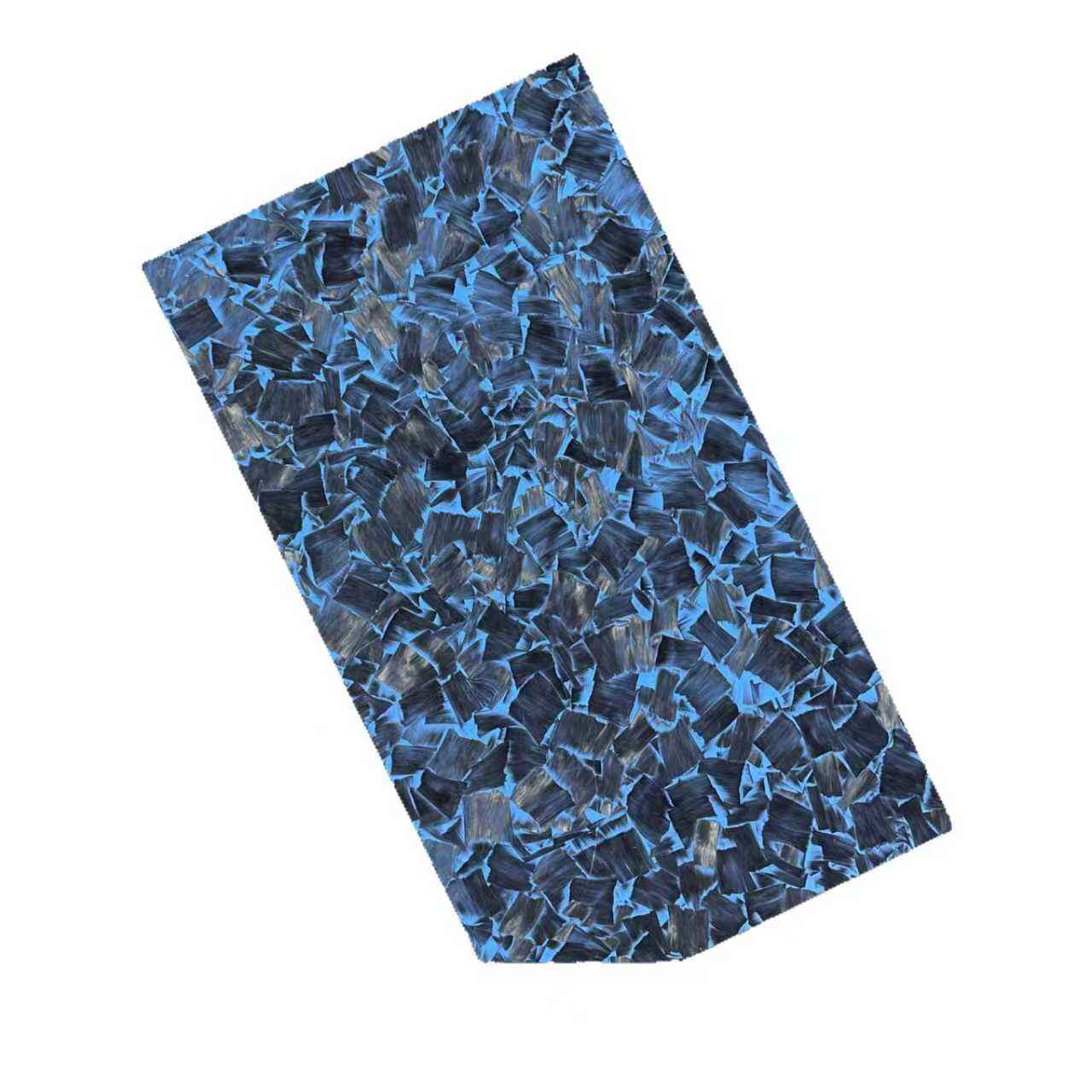

A forged carbon fiber parts manufacturer represents the cutting edge of advanced materials production, specializing in creating high performance components through innovative carbon fiber compression molding technology. This manufacturing process combines precision engineering with state of the art materials science to produce lightweight, durable parts that exceed traditional manufacturing capabilities. The facility utilizes advanced automation systems and quality control measures to ensure consistent production of complex geometries while maintaining superior structural integrity. The manufacturing process begins with precisely cut carbon fiber pieces that are strategically placed in specialized molds, then subjected to carefully controlled pressure and temperature conditions. This results in parts that feature unique aesthetic patterns while delivering exceptional strength to weight ratios. The manufacturer's capabilities extend across various industries, including automotive, aerospace, medical devices, and high end consumer products. Their production line incorporates real time monitoring systems and adaptive process controls to maintain optimal manufacturing conditions throughout each cycle. The facility also maintains comprehensive testing laboratories for material verification and quality assurance, ensuring each component meets or exceeds industry specifications.