forged carbon fiber parts price

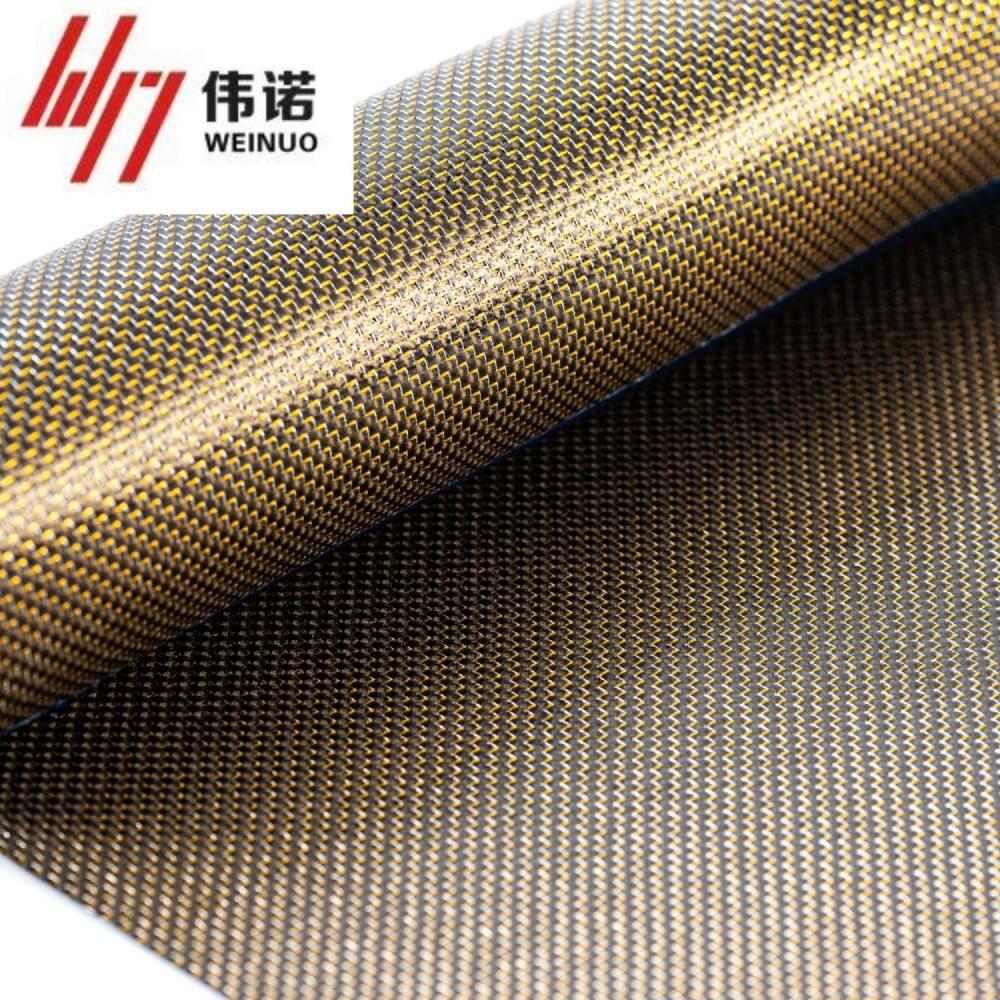

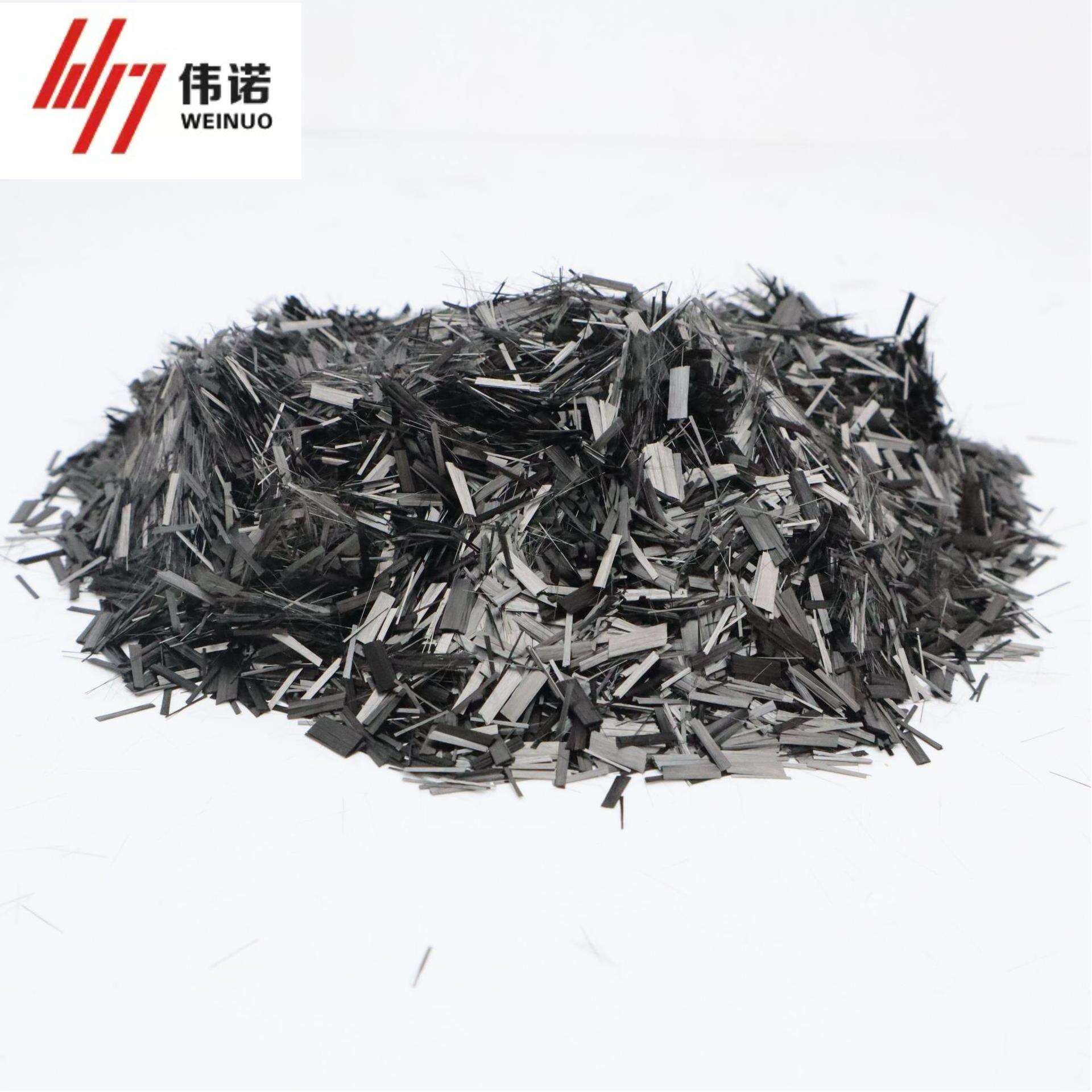

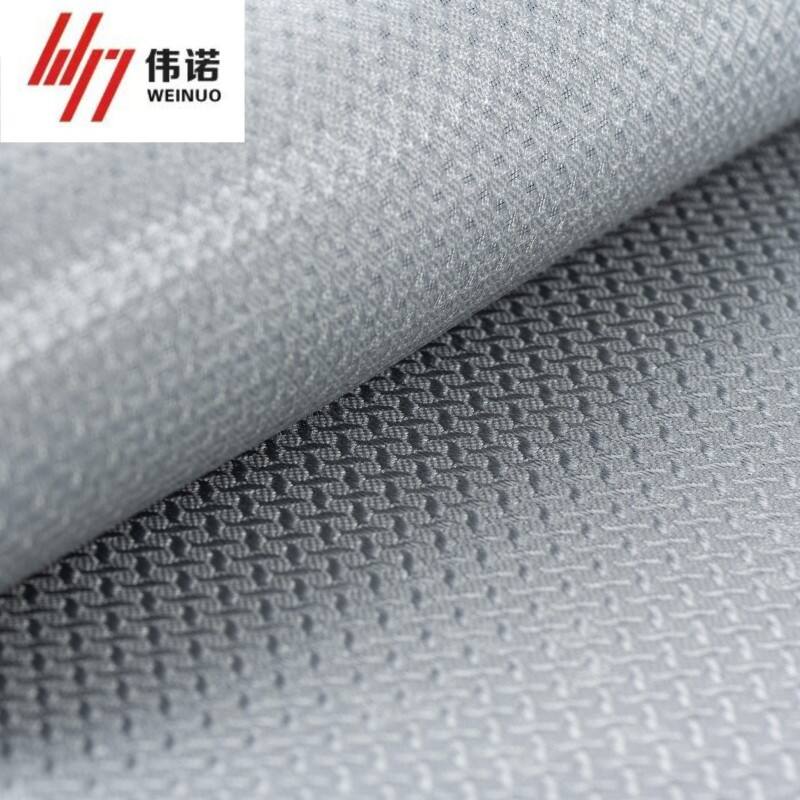

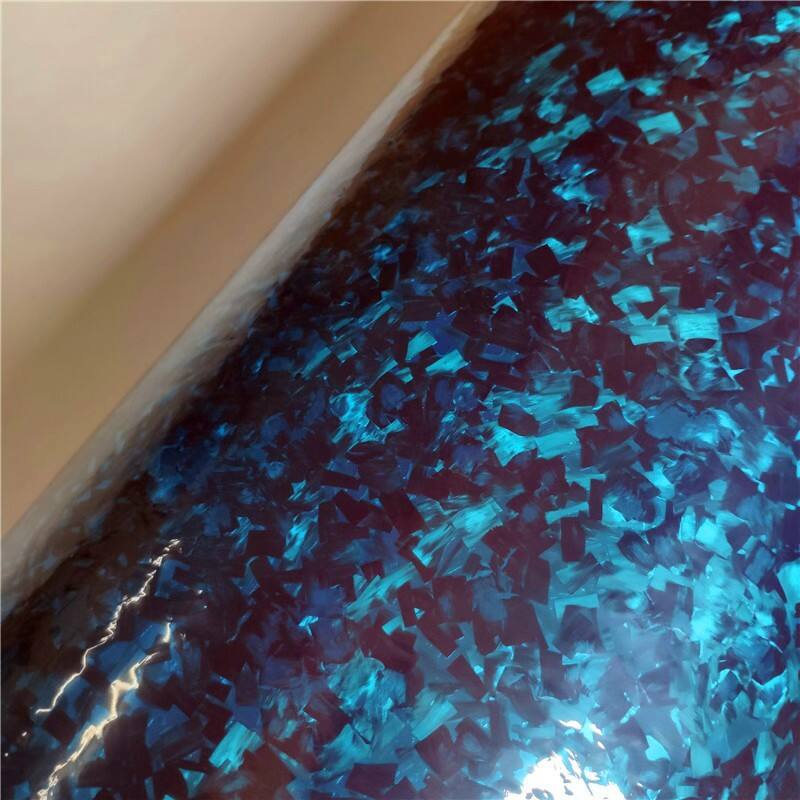

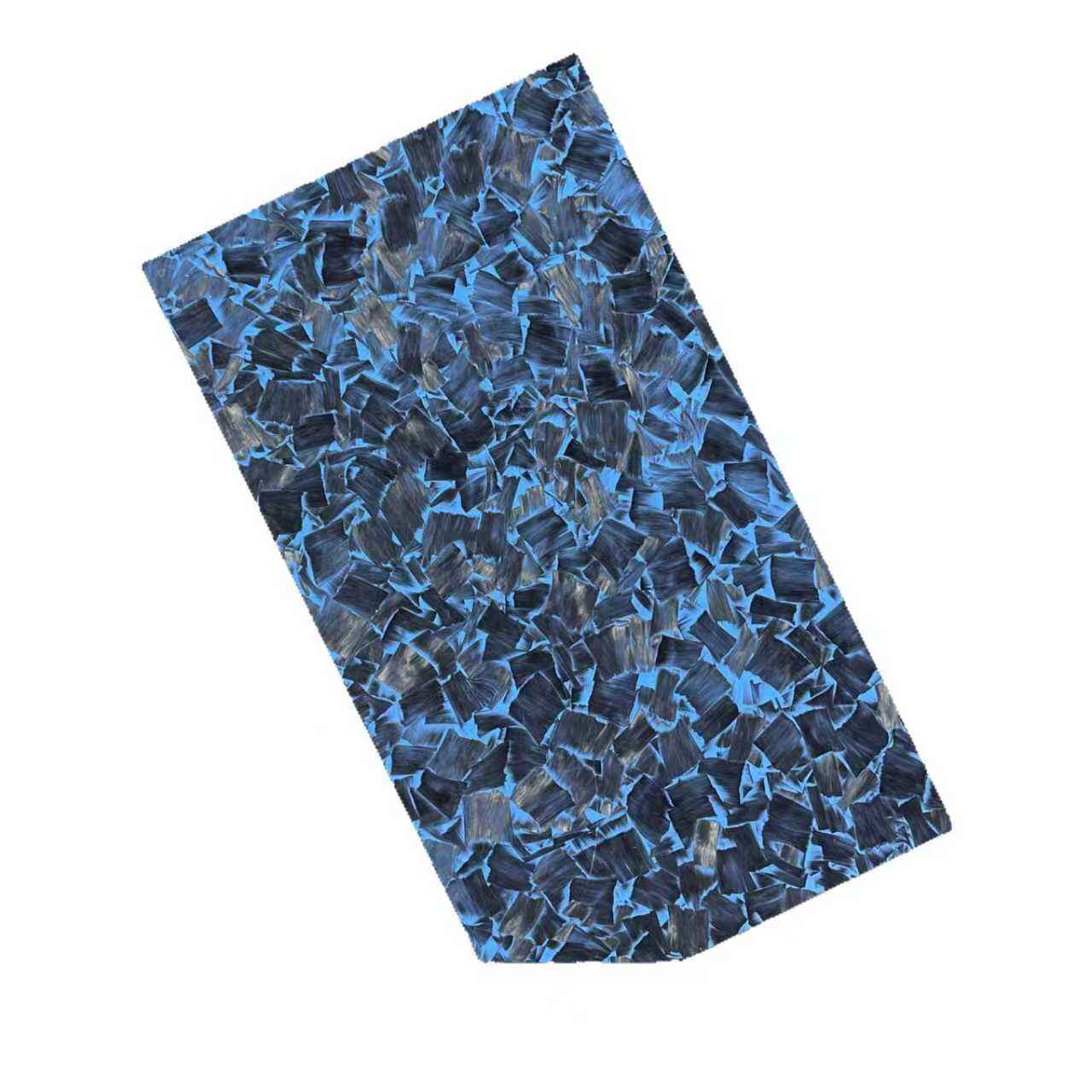

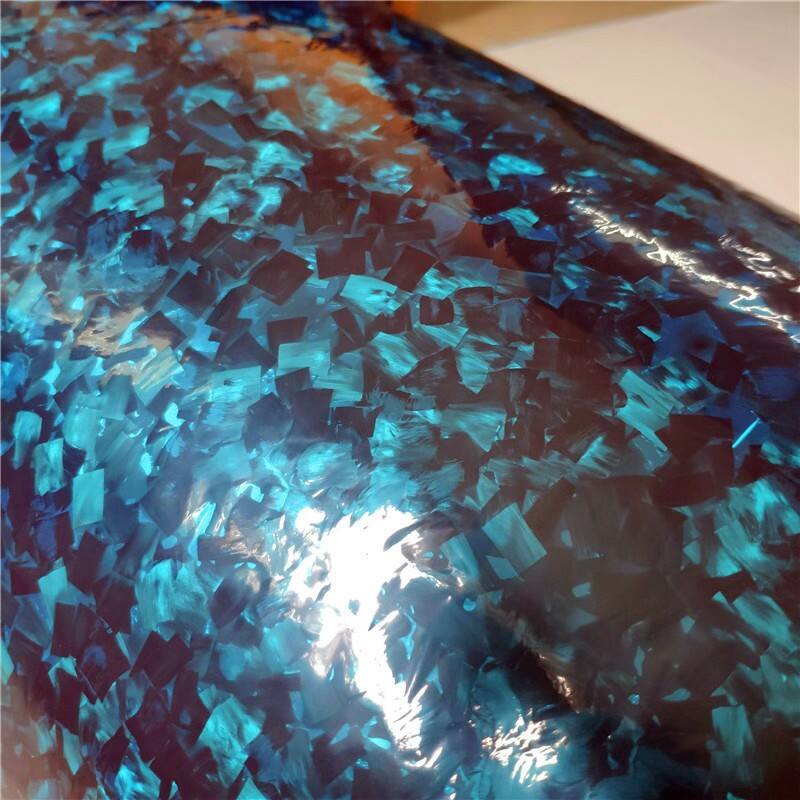

Forged carbon fiber parts pricing represents a crucial consideration in the automotive and aerospace industries, reflecting the advanced manufacturing processes and superior material properties of this innovative composite. The cost structure typically encompasses raw material expenses, specialized manufacturing equipment, skilled labor, and quality control measures. Prices vary significantly based on part complexity, size, and production volume, ranging from hundreds to thousands of dollars per component. The manufacturing process involves precise pressure and temperature control, utilizing chopped carbon fiber sheets impregnated with resin, which are then compressed in specialized molds. This technique allows for more complex geometries than traditional carbon fiber layup methods while maintaining exceptional strength-to-weight ratios. The pricing also factors in the reduced production time compared to traditional carbon fiber manufacturing, though initial tooling costs can be higher. Modern forged carbon fiber parts offer superior performance characteristics, including enhanced structural integrity, reduced weight, and improved aesthetic appeal, justifying their premium price point in high-end applications.