high strength forged carbon fiber

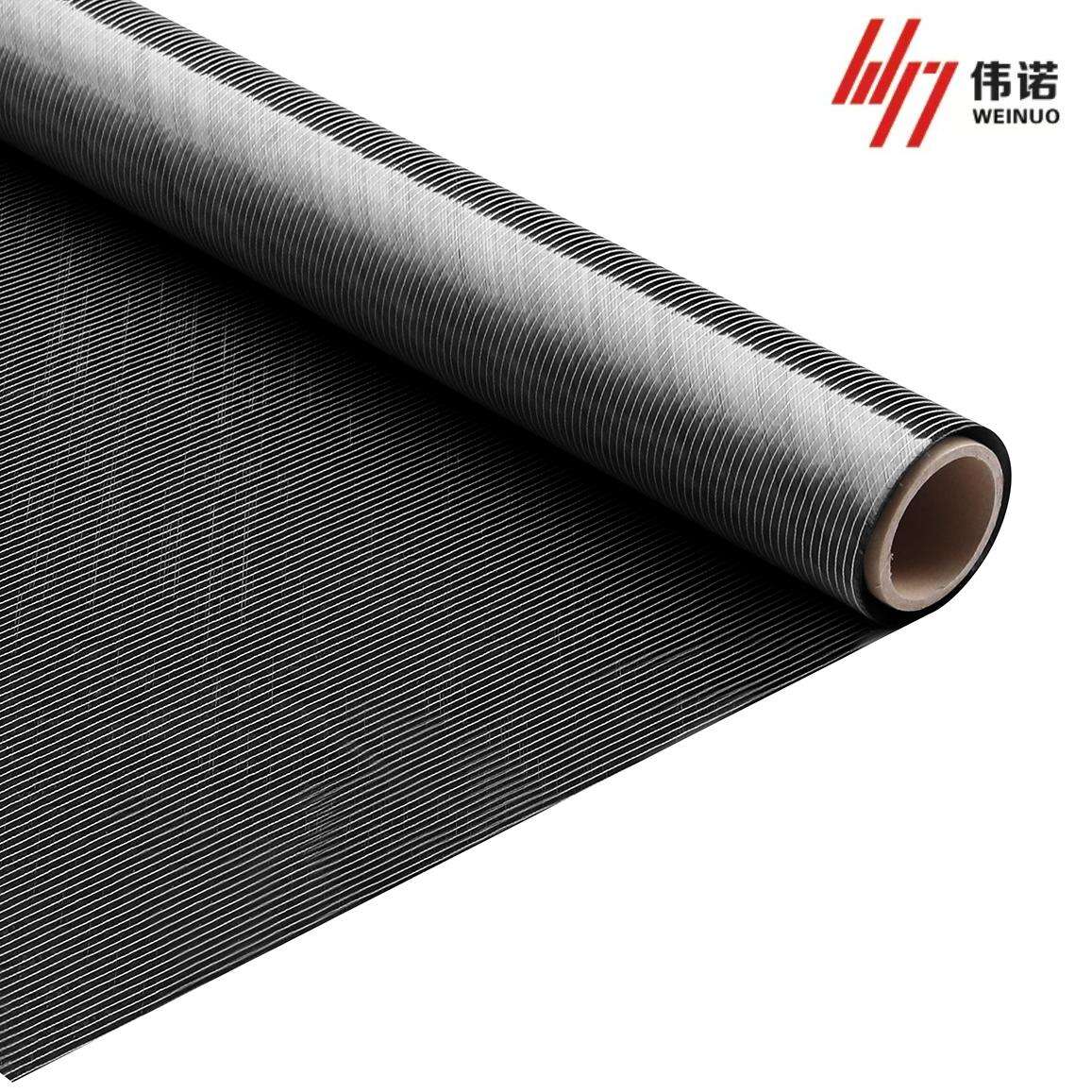

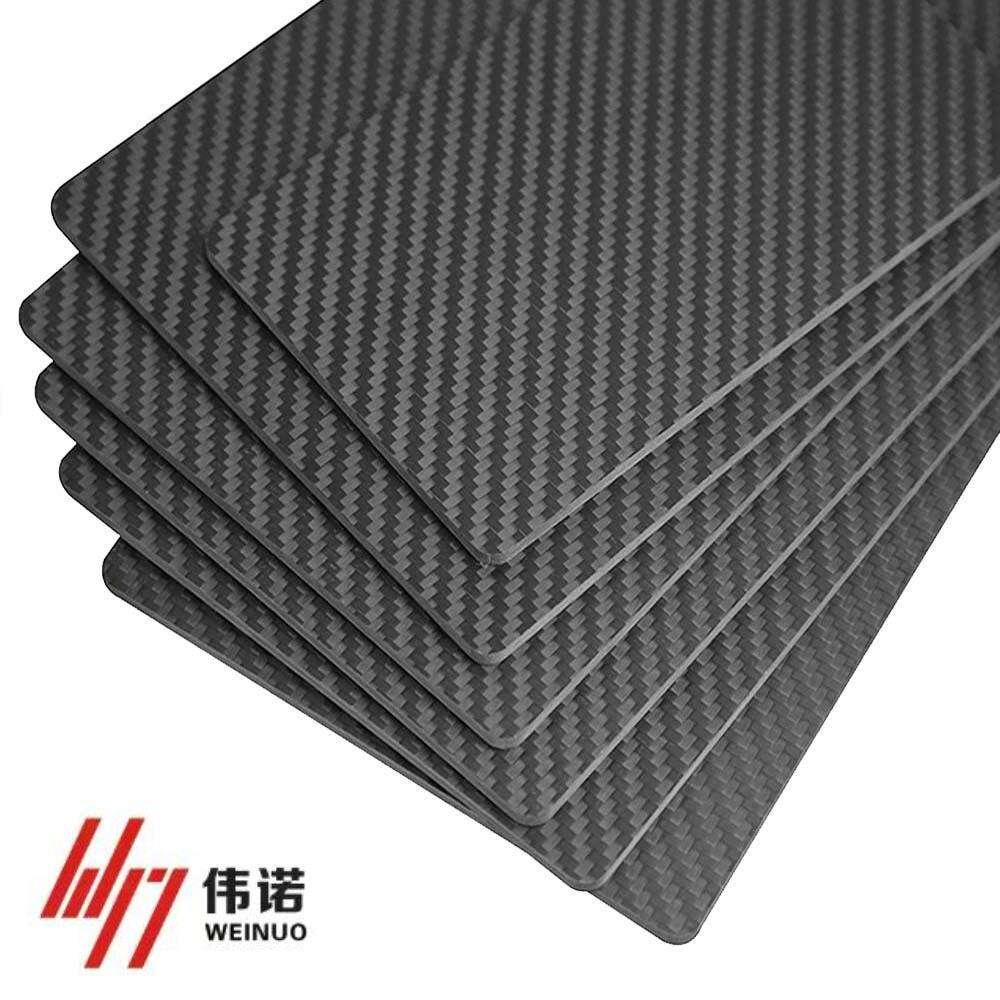

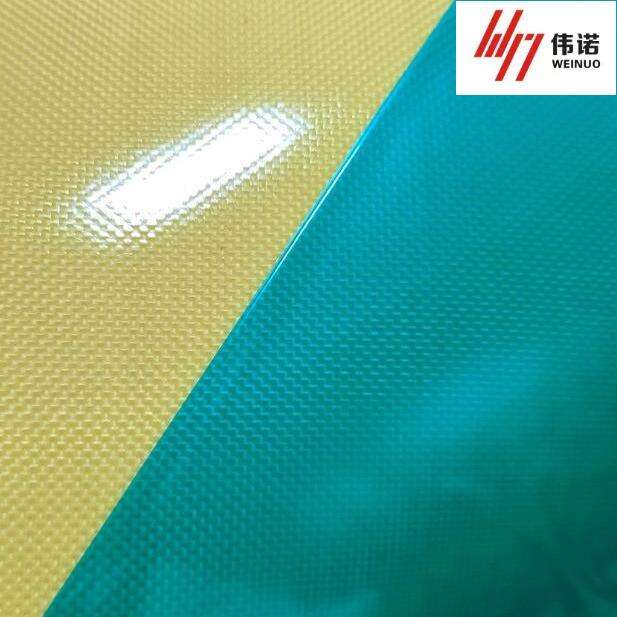

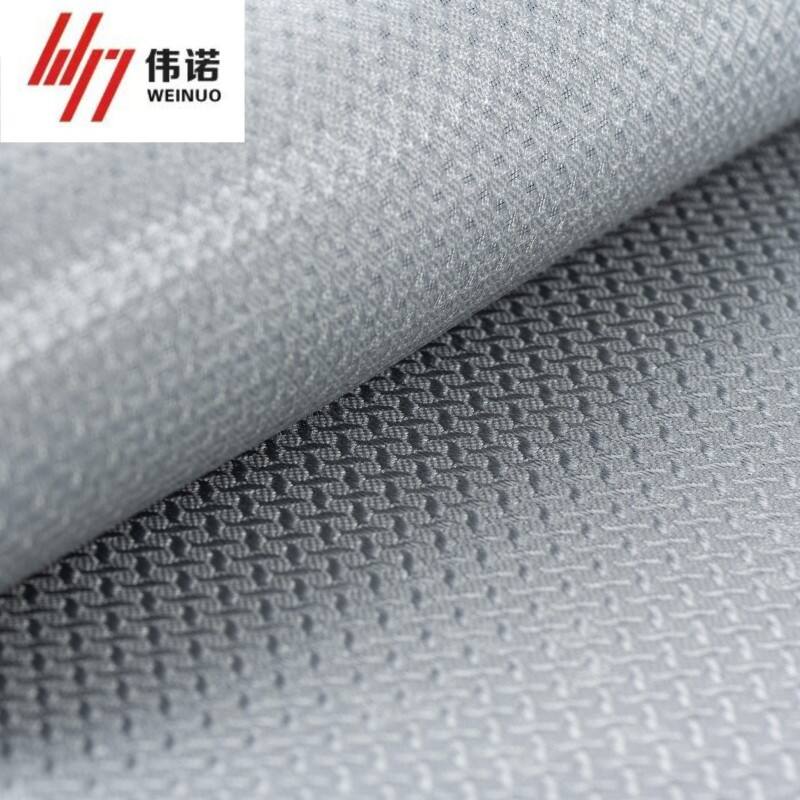

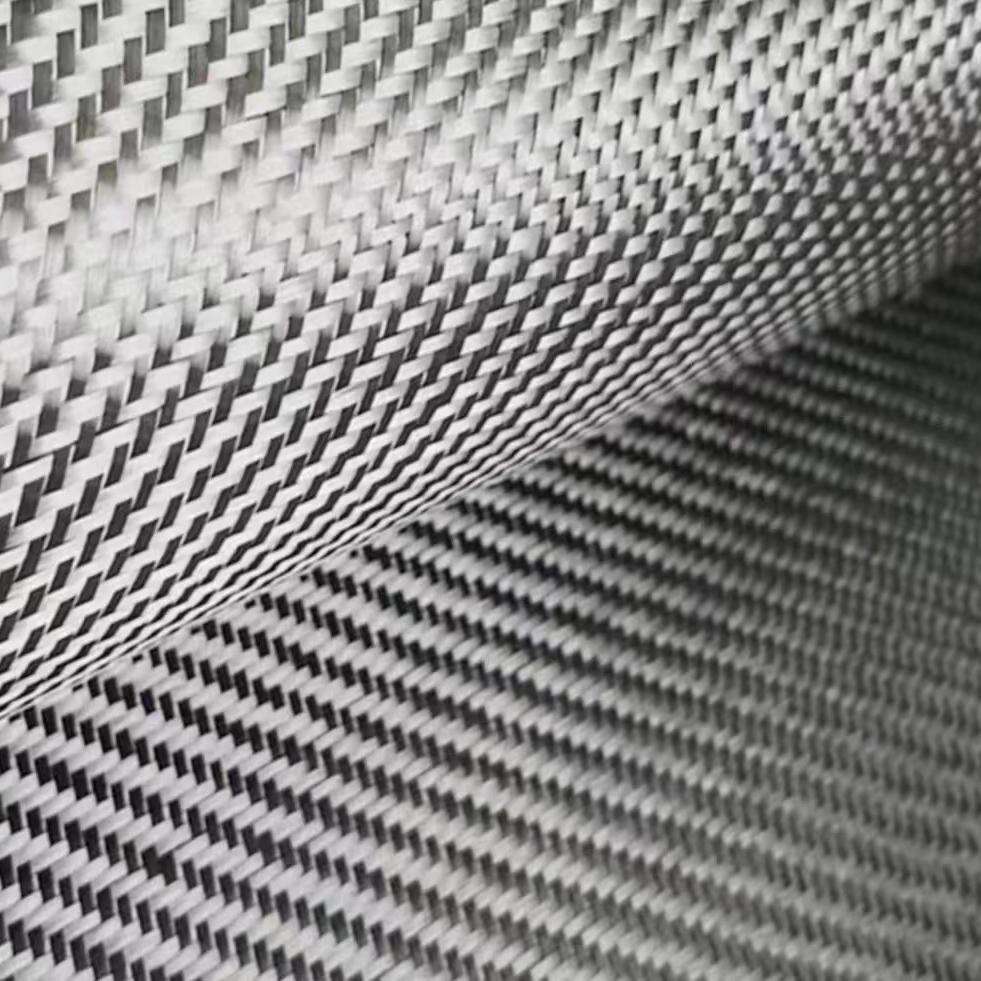

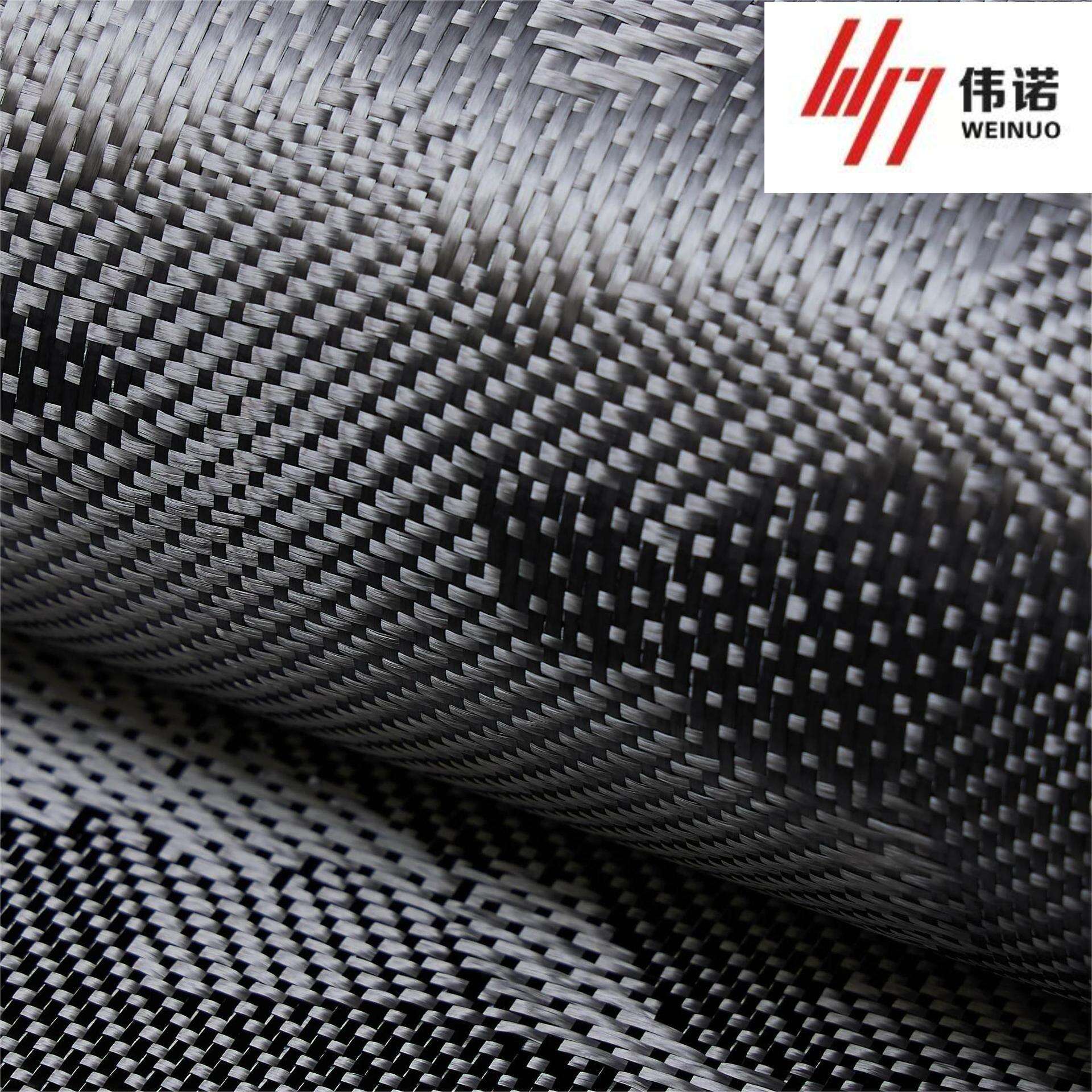

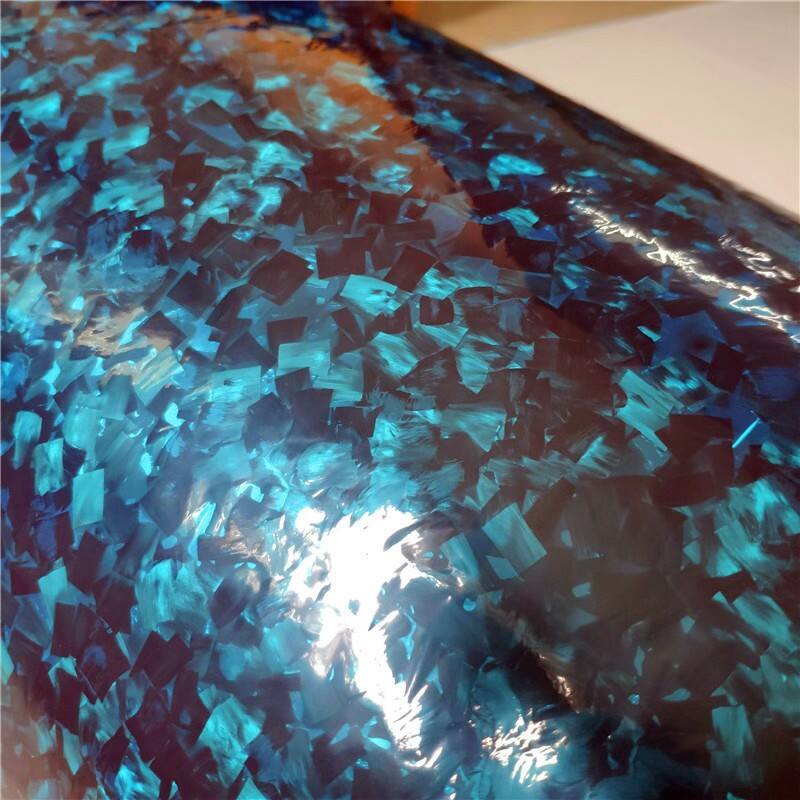

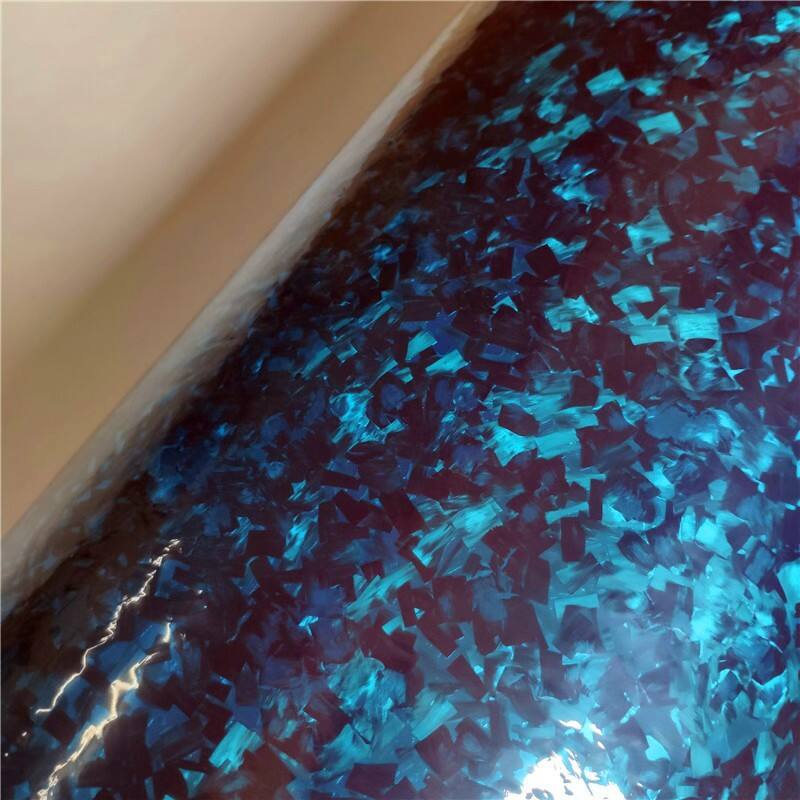

High strength forged carbon fiber represents a revolutionary advancement in composite materials technology, combining exceptional strength with remarkable versatility. This innovative material is created through a specialized forging process that aligns carbon fibers in multiple directions, resulting in a structure that surpasses traditional carbon fiber in both strength and durability. The manufacturing process involves precise pressure and temperature control, creating a dense, void-free material that exhibits superior mechanical properties. Unlike traditional carbon fiber, which typically features a woven pattern, forged carbon fiber showcases a unique, marble-like appearance that adds aesthetic value to its functional benefits. The material excels in applications requiring high structural integrity while maintaining minimal weight, making it ideal for automotive components, aerospace parts, and high-performance sporting equipment. Its ability to be molded into complex shapes while maintaining consistent strength throughout the structure has revolutionized product design capabilities. The material's resistance to fatigue, environmental factors, and impact damage further enhances its appeal across various industries. Modern manufacturing techniques allow for precise control over fiber orientation and density, enabling customization for specific performance requirements.