forged carbon fiber parts factory

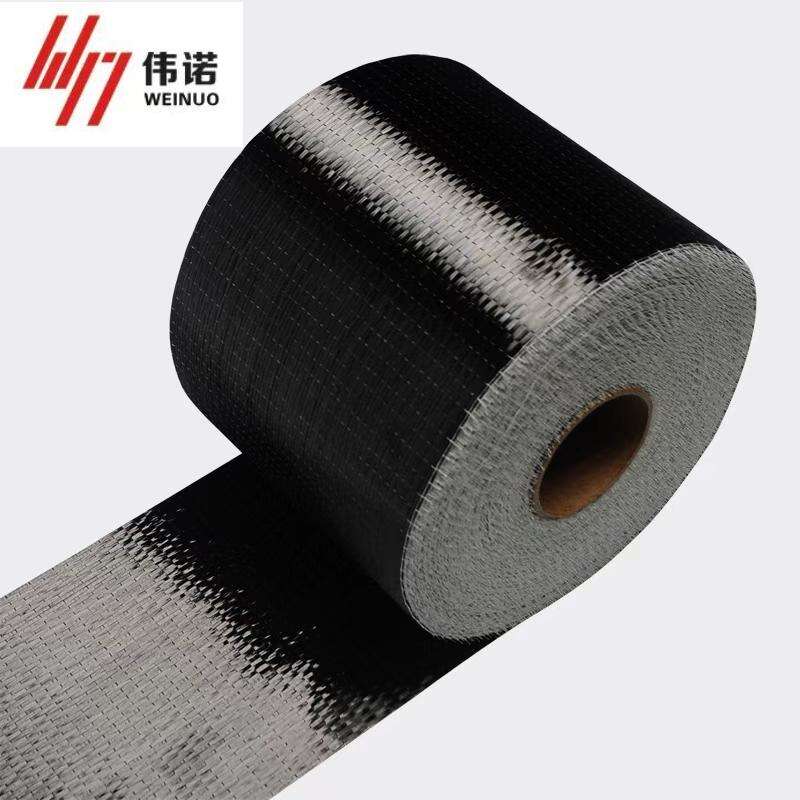

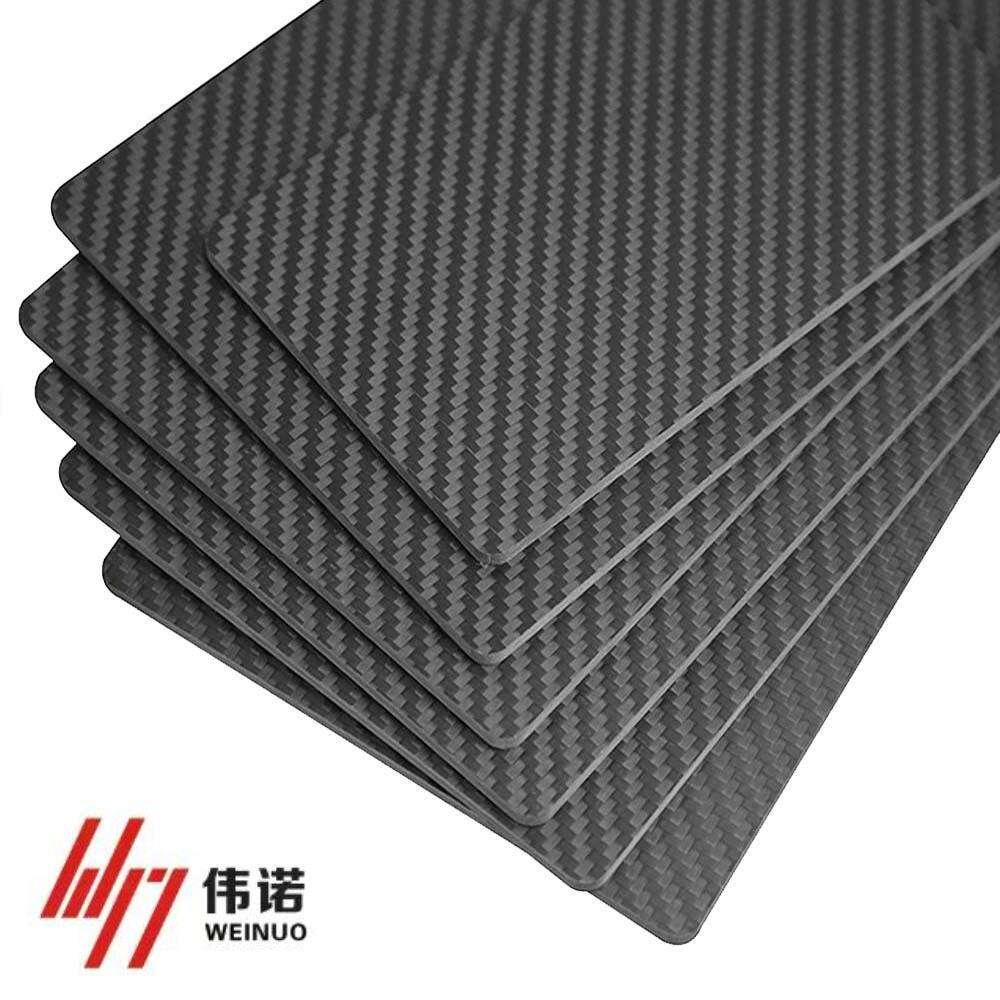

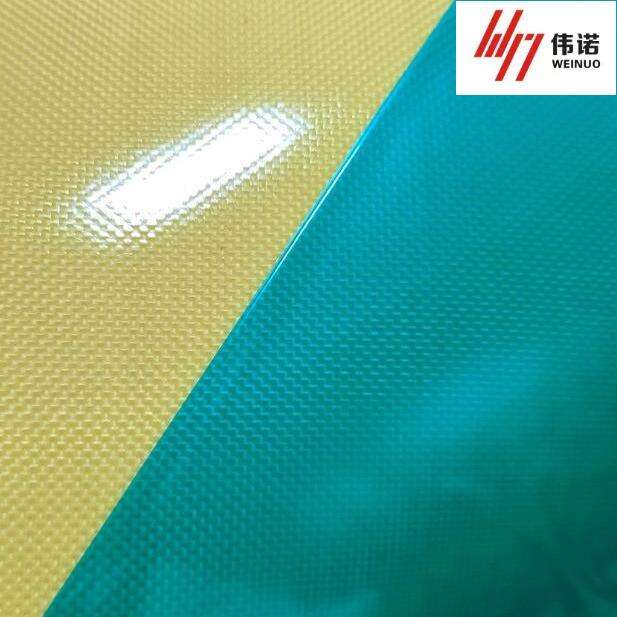

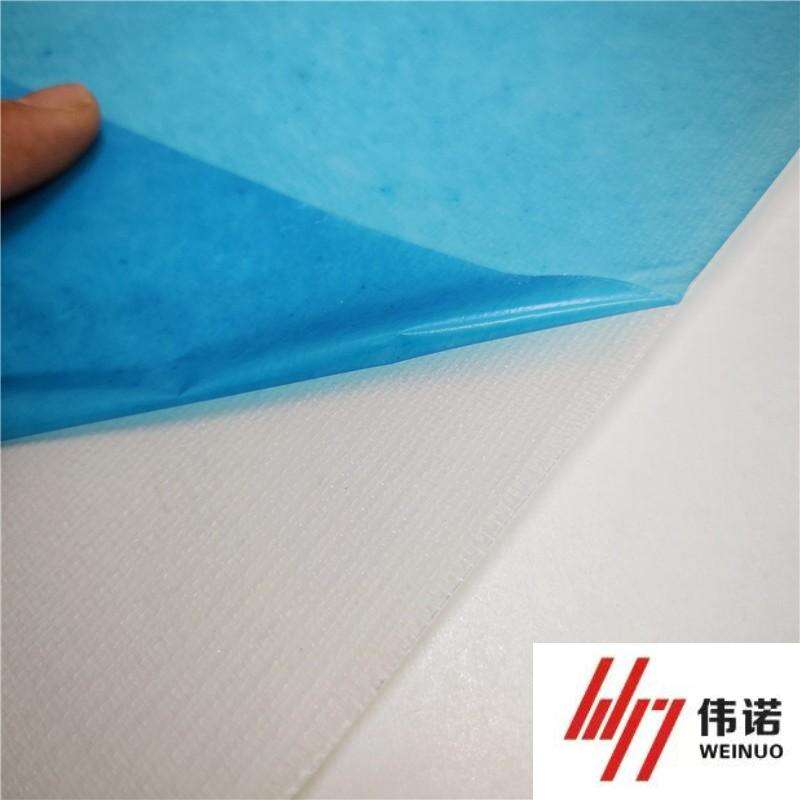

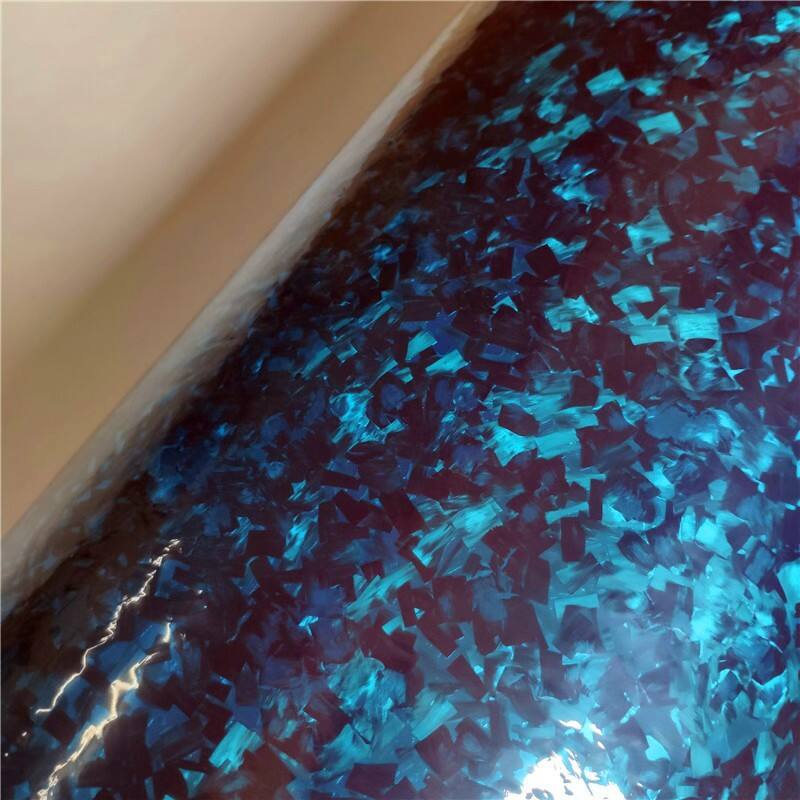

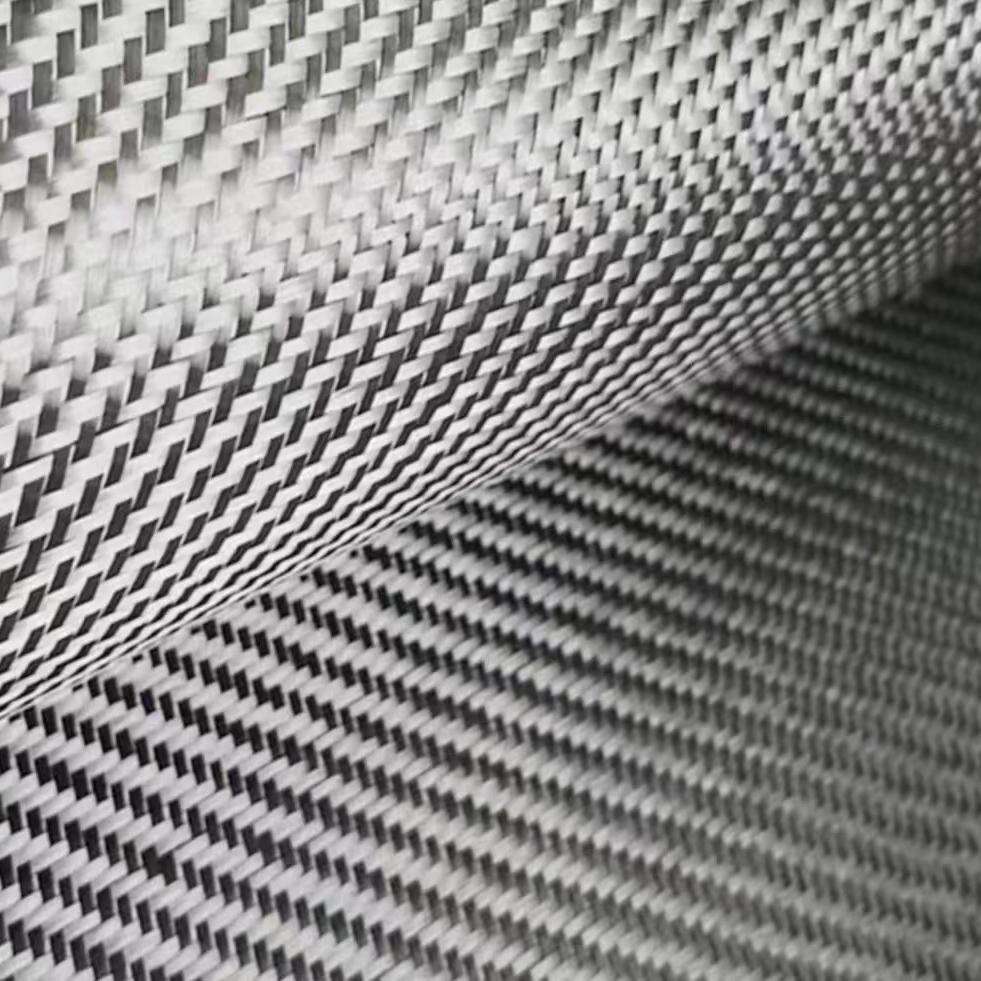

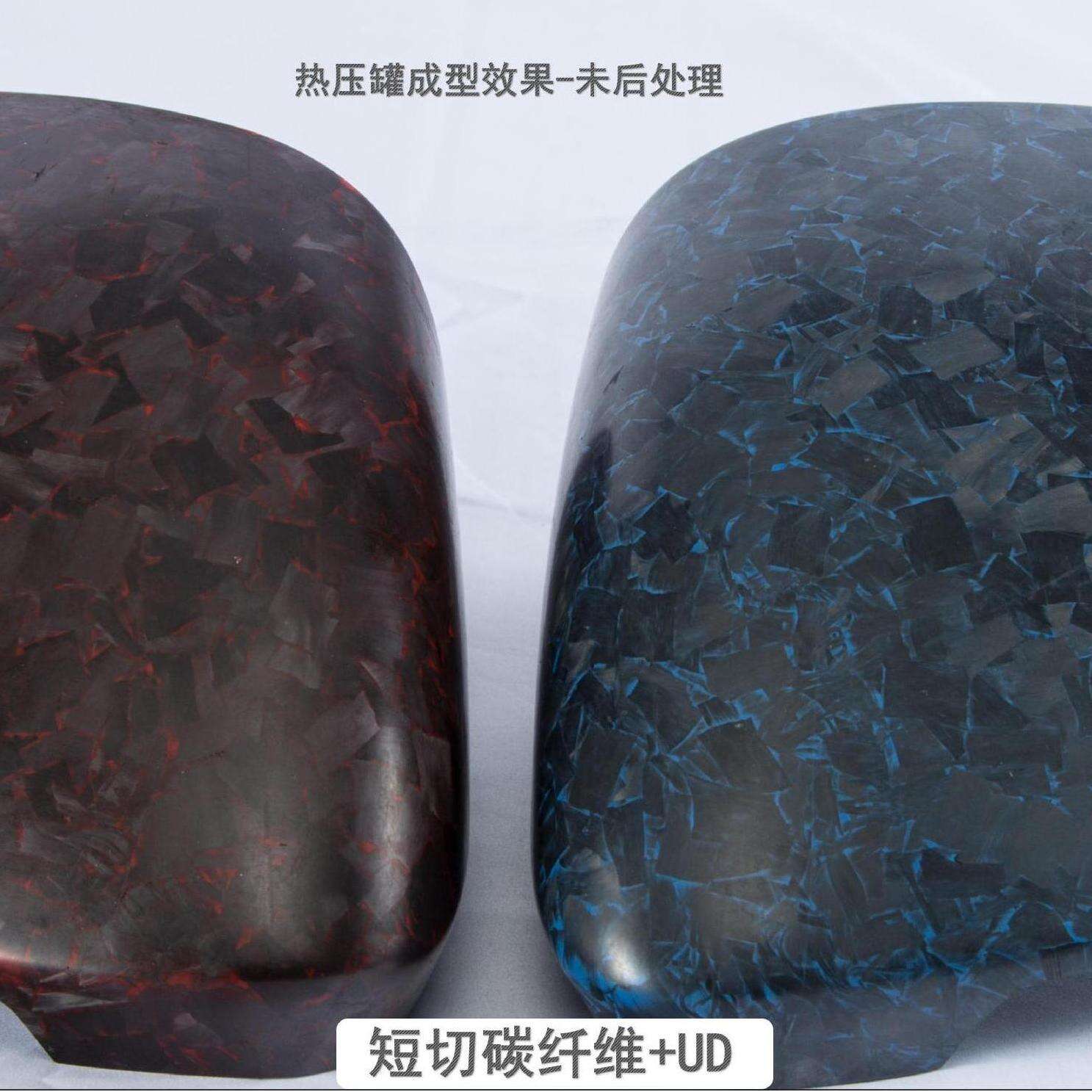

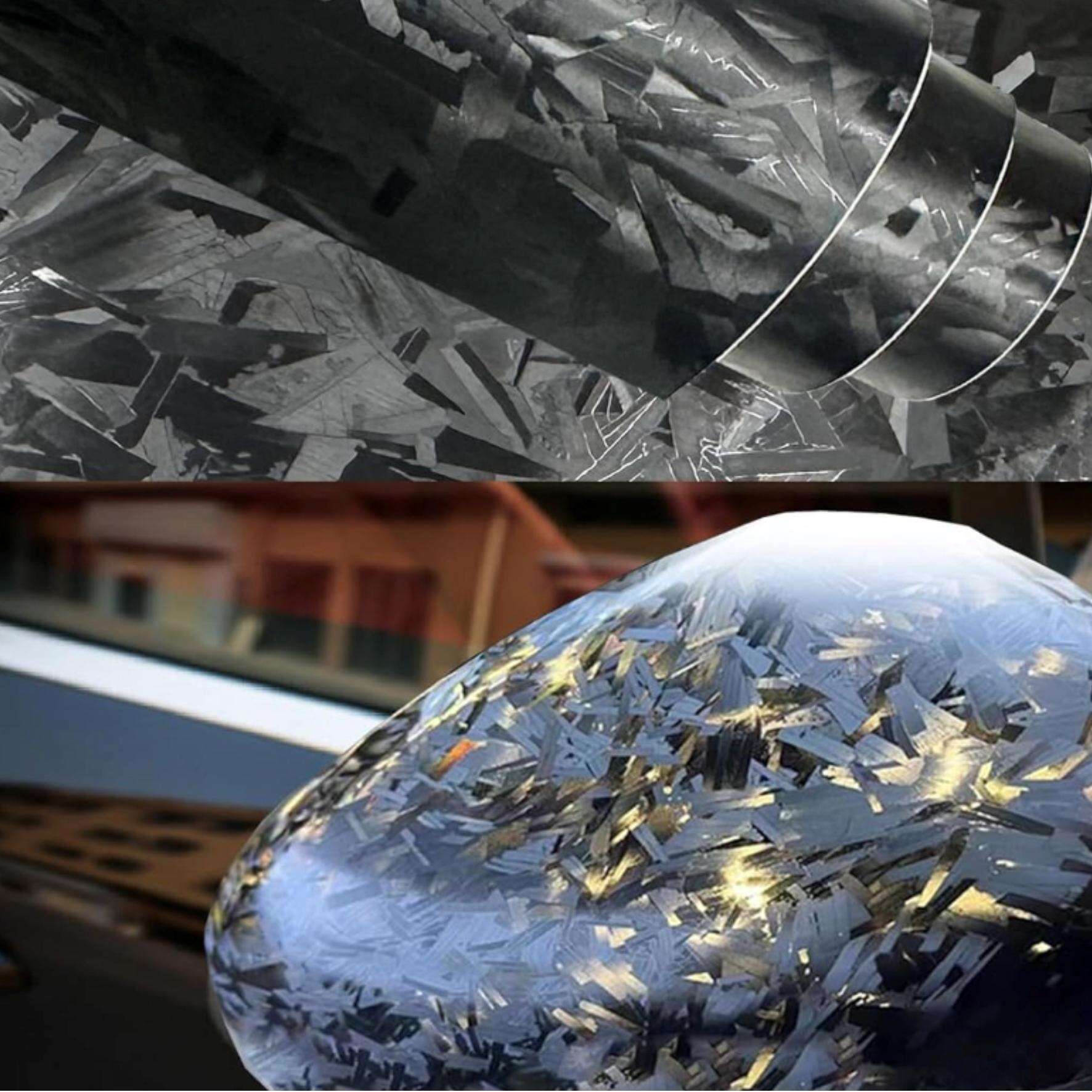

A forged carbon fiber parts factory represents a cutting-edge manufacturing facility dedicated to producing high-performance composite components through innovative forging processes. This state-of-the-art facility combines advanced automation systems with precision engineering to create lightweight, durable parts for various industries. The factory utilizes specialized equipment including hydraulic presses, automated layup systems, and quality control stations to transform raw carbon fiber materials into complex geometric shapes. The manufacturing process involves precise temperature and pressure control systems, ensuring consistent product quality across all production runs. The facility features multiple production lines capable of simultaneously handling different product specifications, from automotive components to aerospace parts. Advanced curing ovens and cooling systems maintain optimal conditions for carbon fiber processing, while integrated quality control systems perform real-time monitoring of each component. The factory employs sophisticated CAD/CAM technology for precise mold design and manufacturing, supported by a team of skilled engineers and technicians. Environmental control systems maintain ideal temperature, humidity, and dust levels throughout the facility, ensuring optimal production conditions. The factory's layout optimizes workflow efficiency, with dedicated areas for material storage, production, quality control, and finishing processes. This comprehensive setup enables the facility to produce complex carbon fiber components with superior strength-to-weight ratios while maintaining high production efficiency and consistent quality standards.