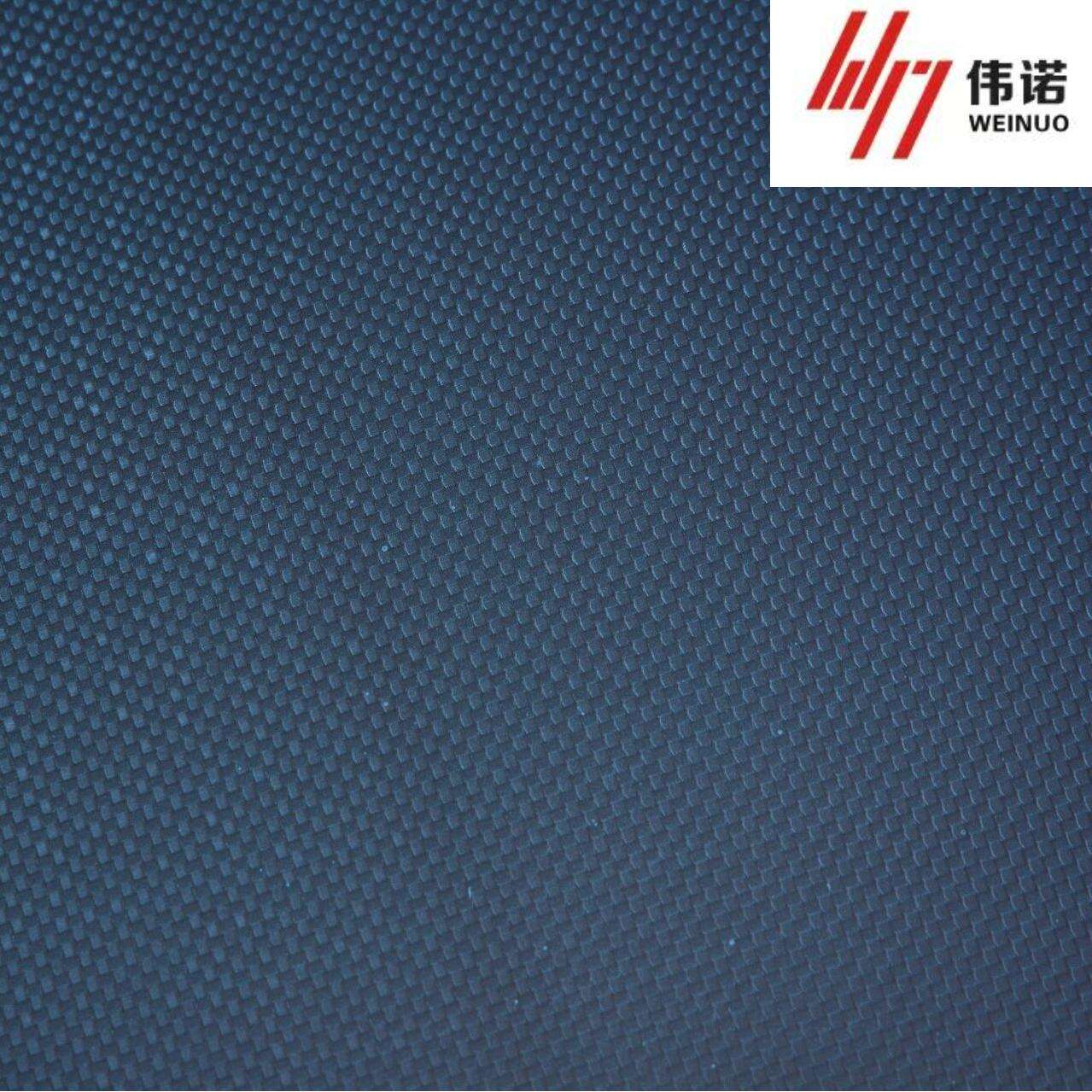

prepreg unidirectional carbon fiber

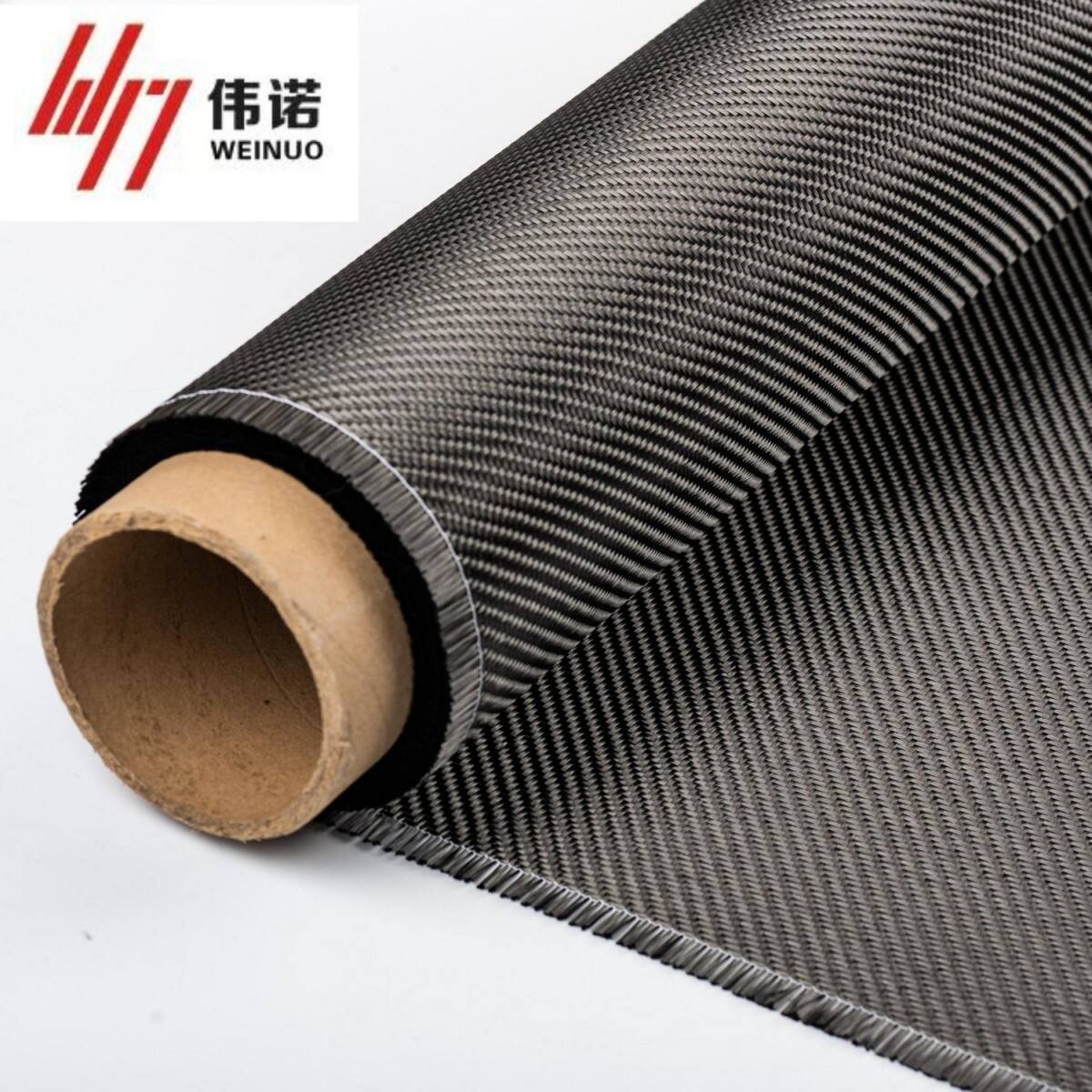

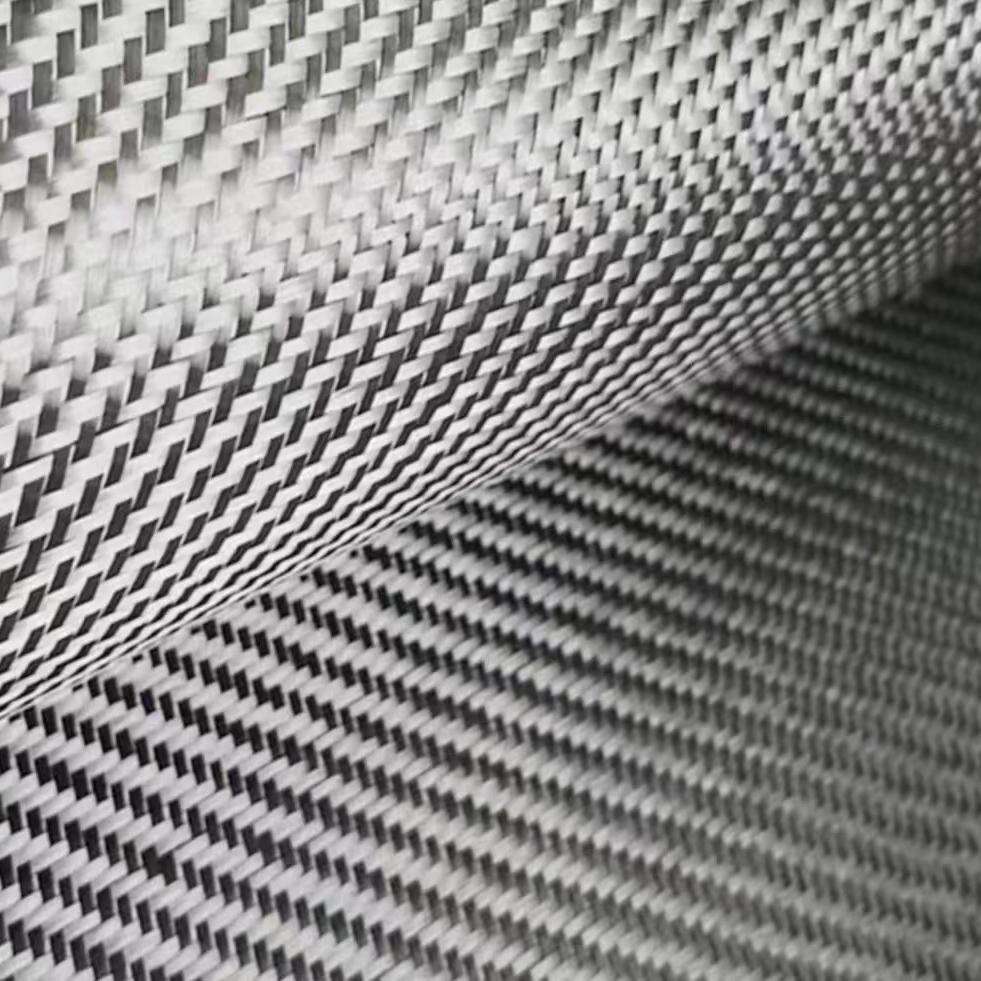

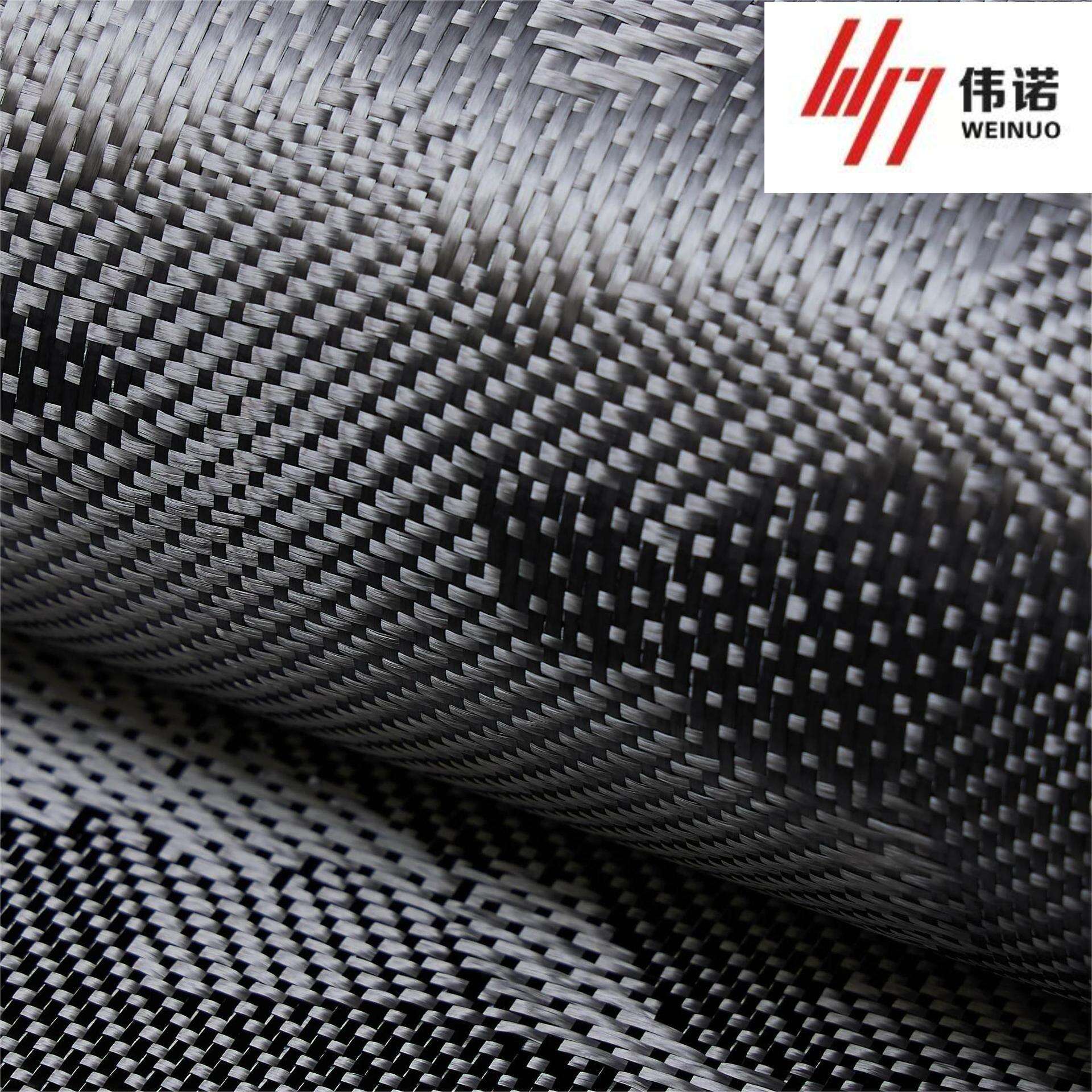

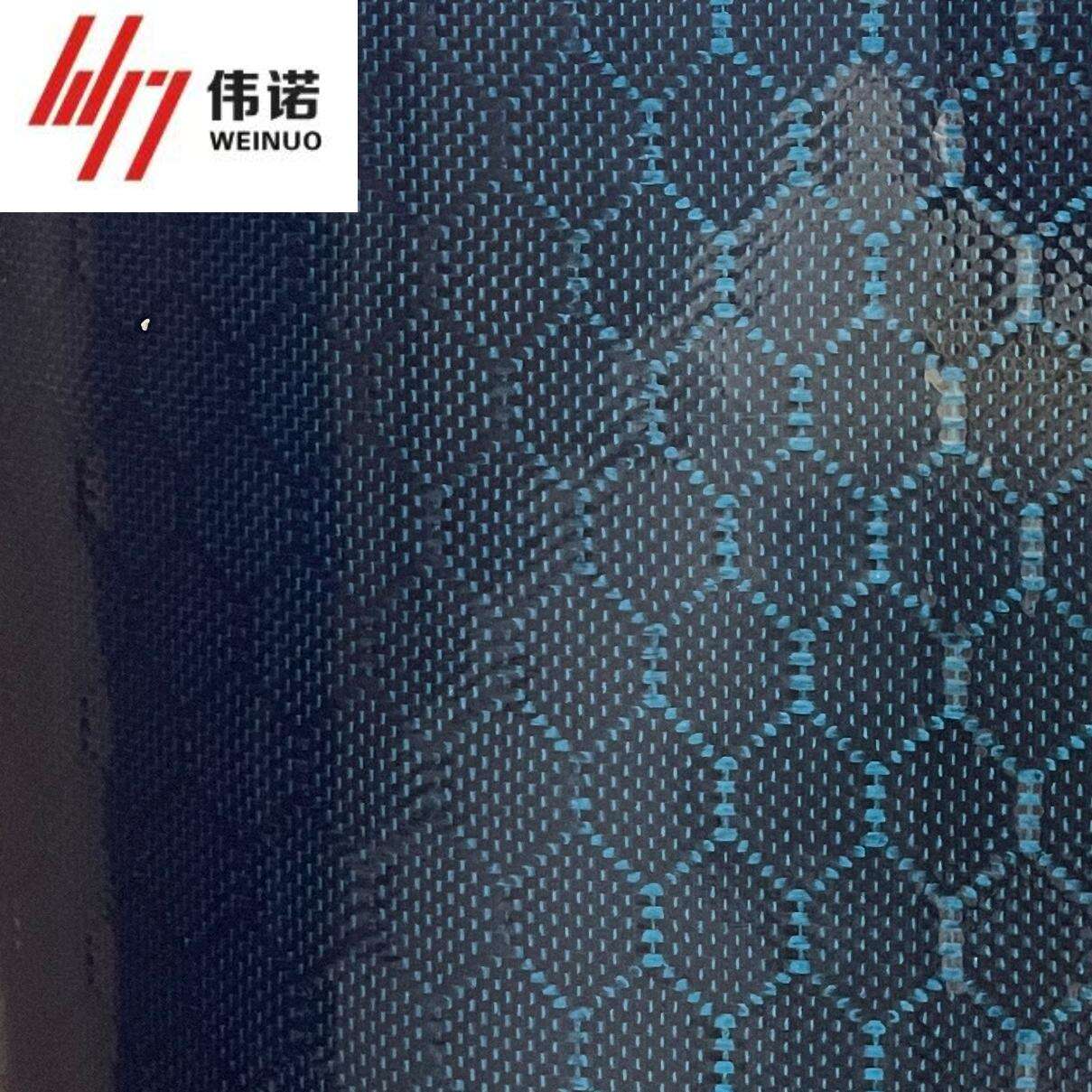

Prepreg unidirectional carbon fiber represents a cutting-edge composite material that consists of aligned carbon fiber strands pre-impregnated with a precisely measured resin matrix. This advanced material is manufactured under controlled conditions where continuous carbon fibers are arranged parallel to each other and uniformly coated with a specific amount of thermoset or thermoplastic resin. The unidirectional orientation of fibers provides exceptional strength and stiffness in the fiber direction, making it ideal for applications requiring high performance in a specific loading direction. The pre-impregnation process ensures consistent resin content and fiber distribution throughout the material, eliminating the variability often associated with wet layup processes. These prepregs are typically supplied in roll form with a protective backing paper and require storage at low temperatures to prevent premature curing. When used in manufacturing, they offer precise fiber placement, controlled resin content, and minimal void content, resulting in superior mechanical properties. Common applications include aerospace components, high-performance sporting goods, automotive parts, and industrial equipment where maximum strength-to-weight ratio is crucial.