prepreg carbon fiber factory

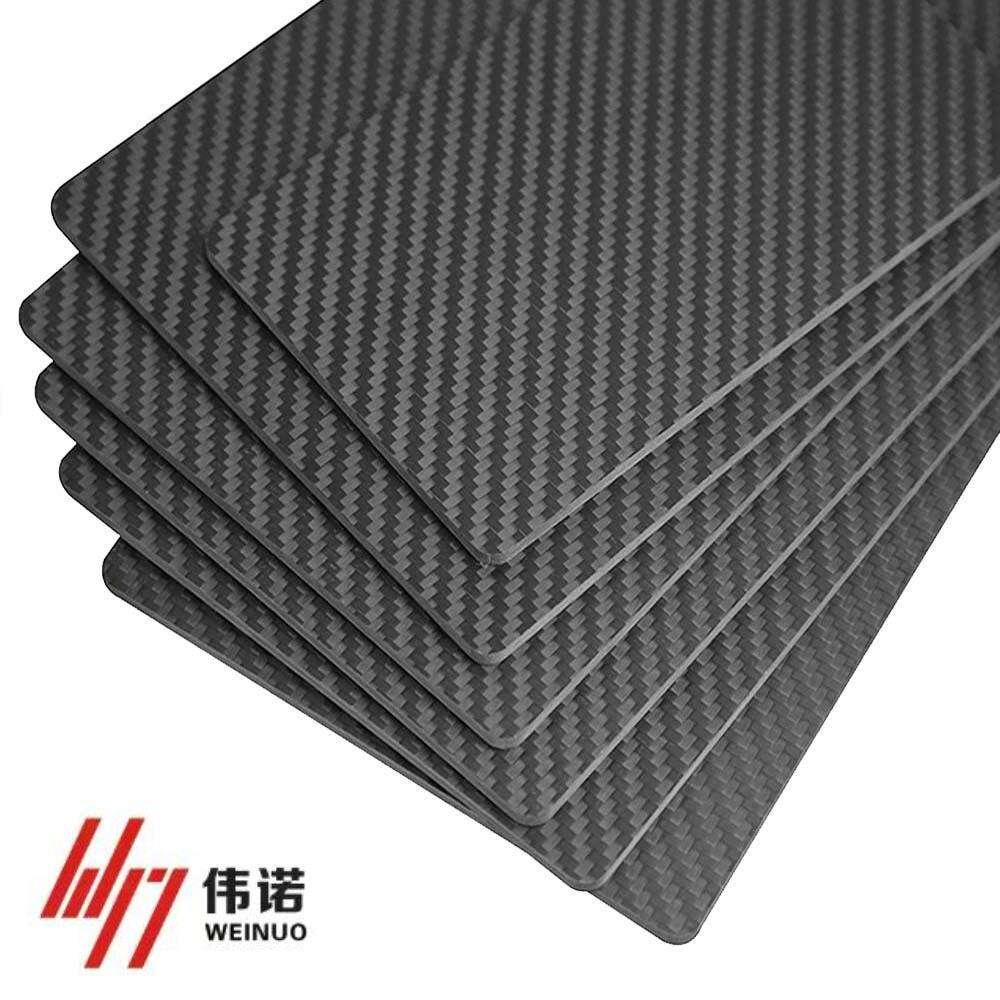

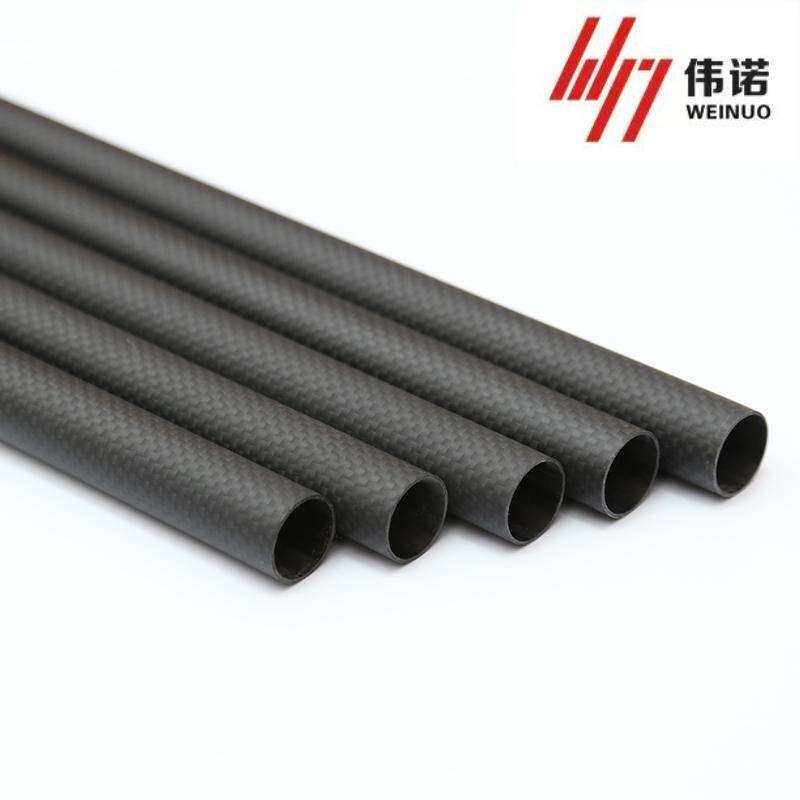

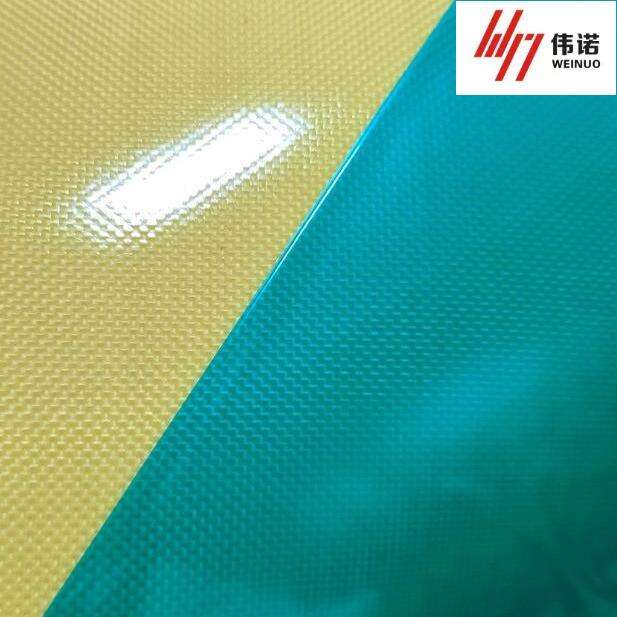

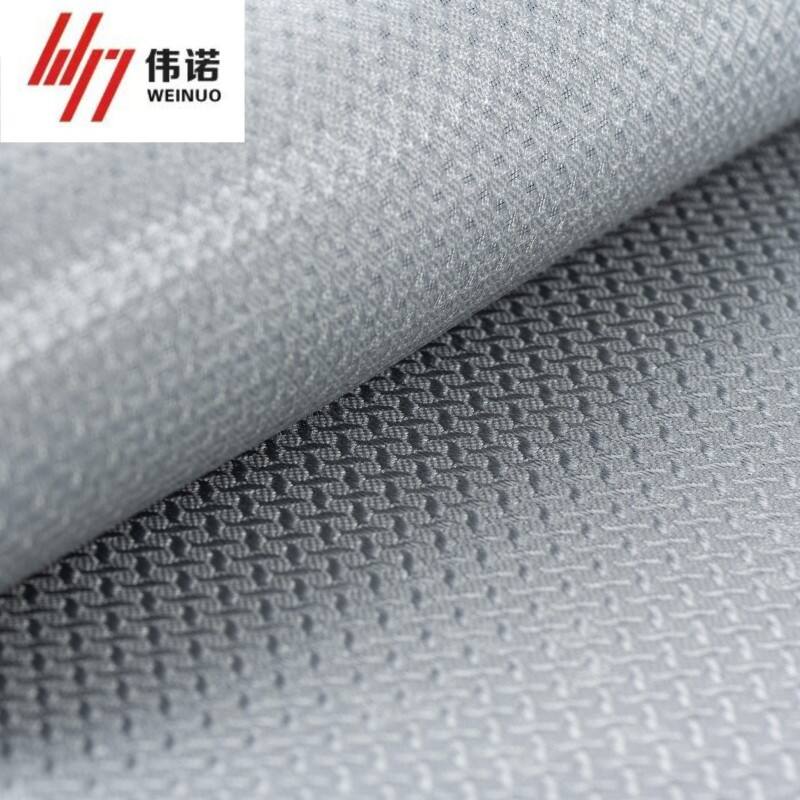

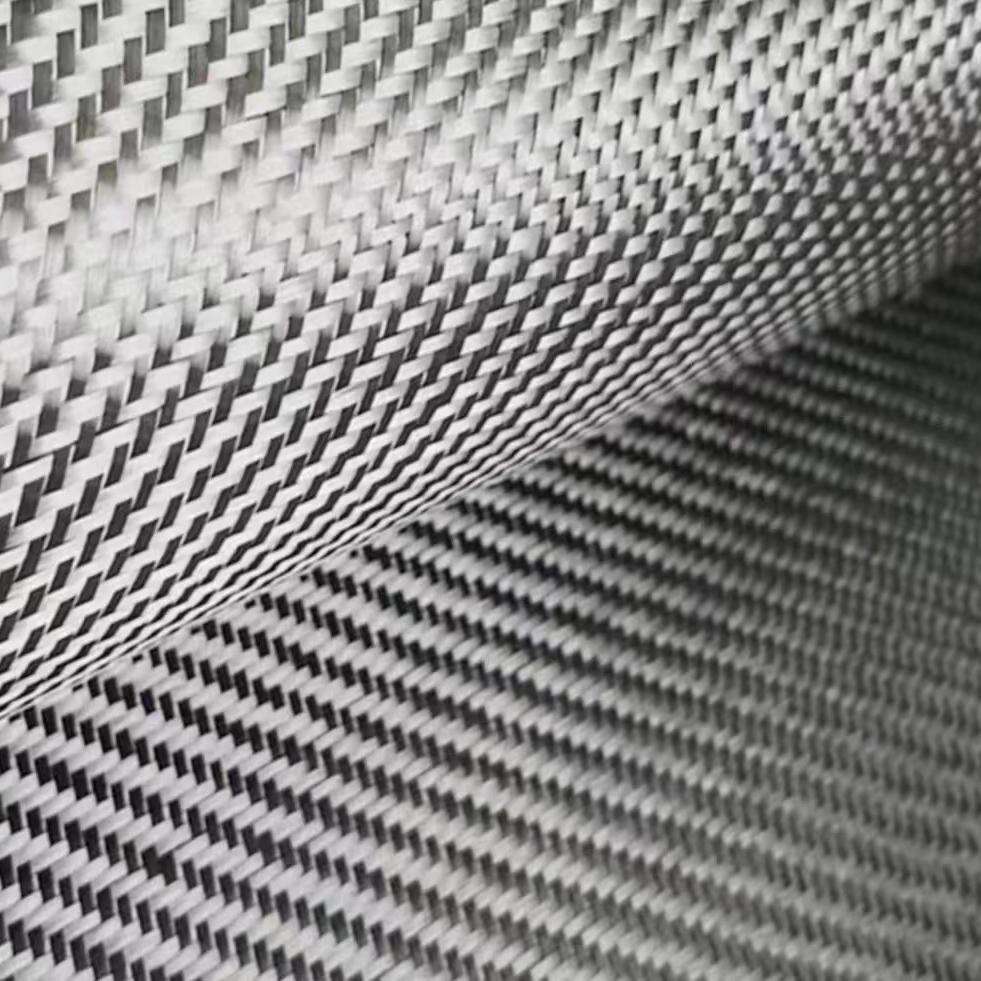

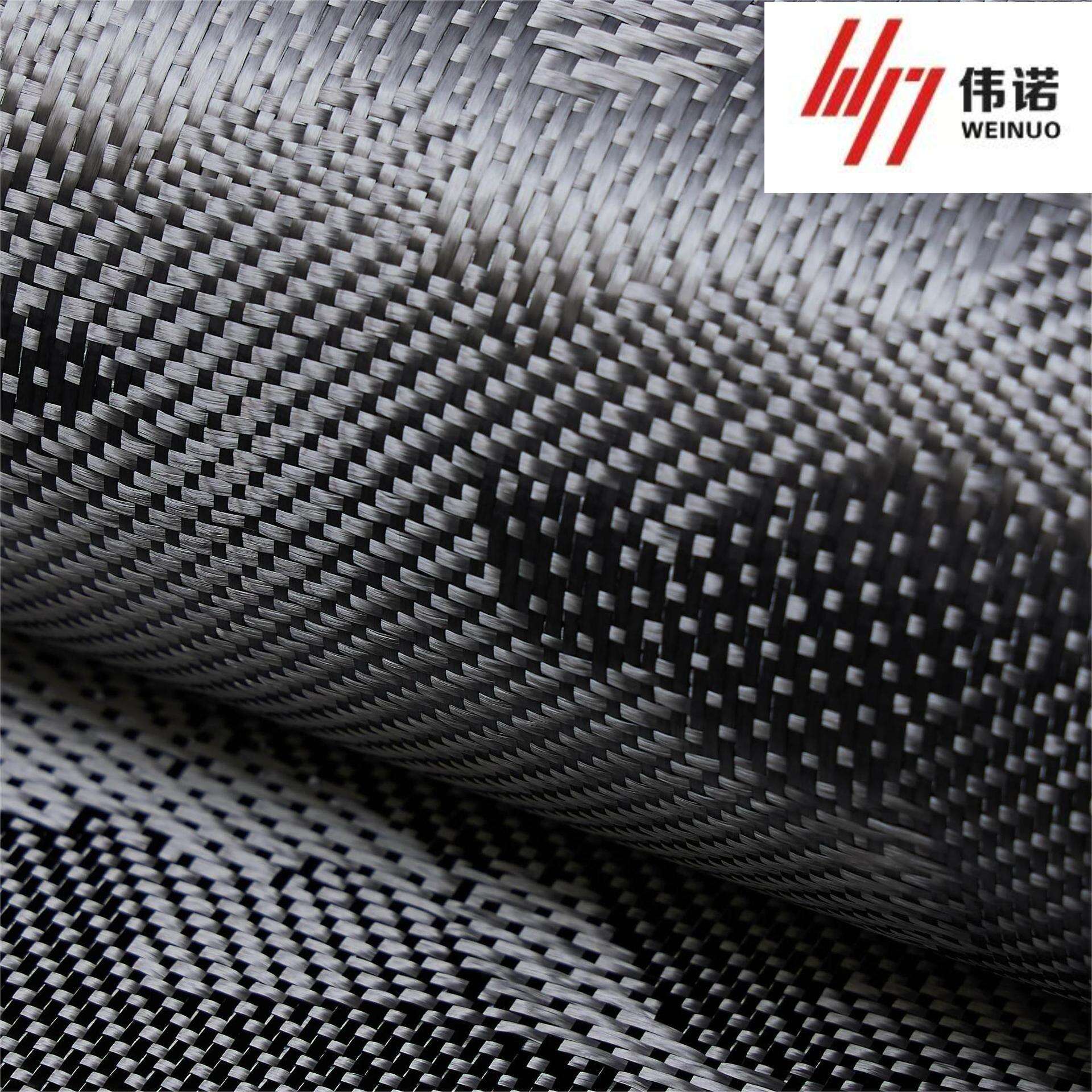

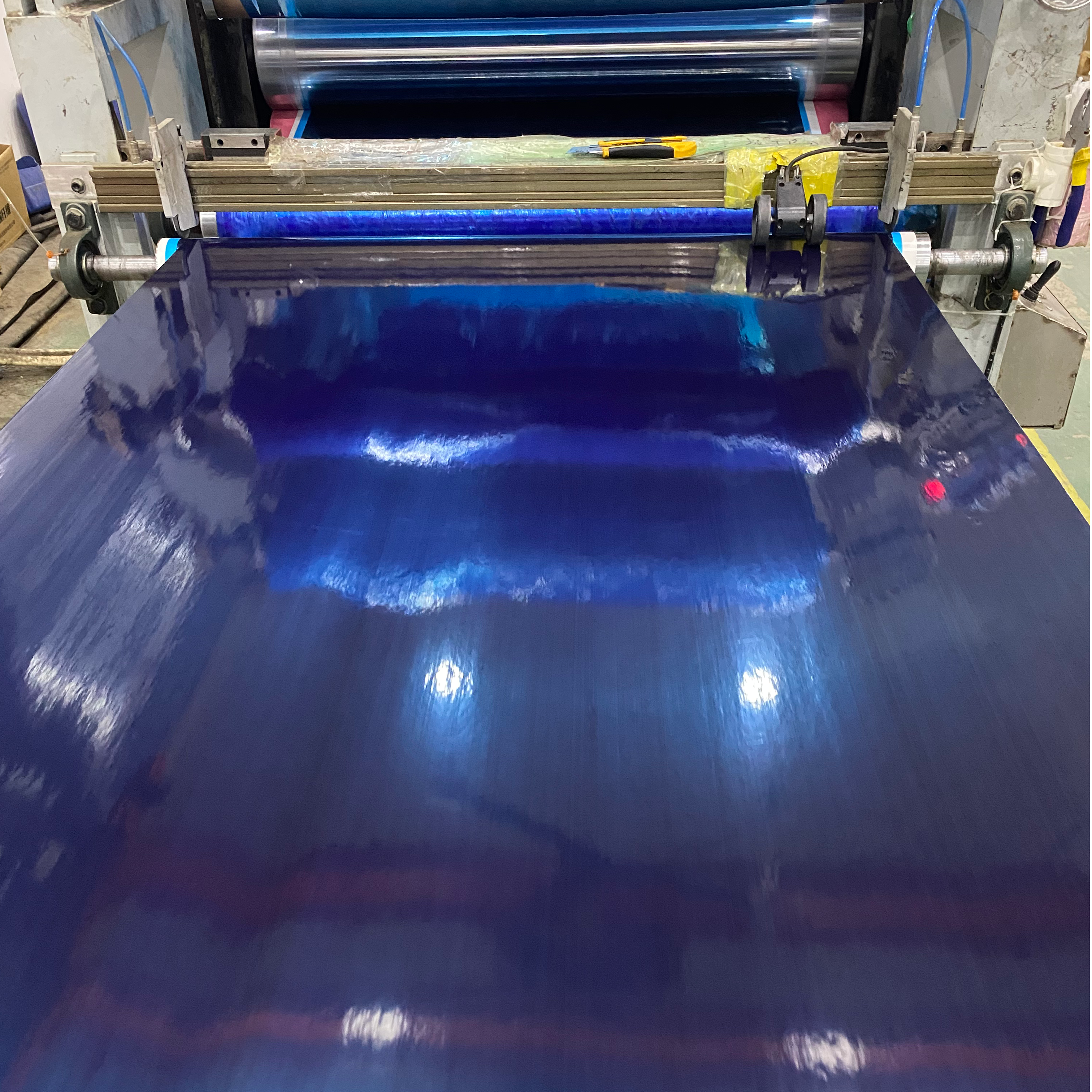

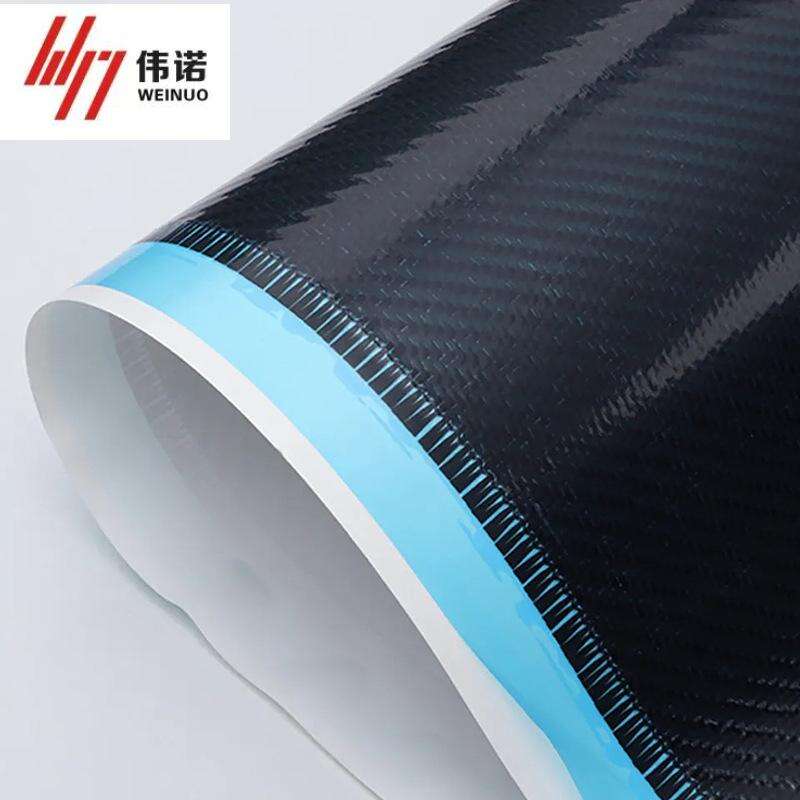

A prepreg carbon fiber factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality pre-impregnated composite materials. These specialized facilities combine advanced automation systems with precise environmental controls to create premium carbon fiber materials pre-infused with carefully formulated resin systems. The factory's core operations include material preparation, precise resin application, environmental control systems, and quality assurance protocols. Advanced clean room facilities maintain strict temperature and humidity controls, ensuring consistent product quality. The production line features sophisticated resin application systems that achieve precise fiber-to-resin ratios, while computerized monitoring systems track every aspect of the manufacturing process. These facilities employ cutting-edge technology for material handling, including automated cutting systems and climate-controlled storage areas for both raw materials and finished products. The factory's capabilities extend to producing various prepreg specifications, from unidirectional tapes to woven fabrics, serving industries such as aerospace, automotive, sporting goods, and industrial applications. Quality control laboratories equipped with advanced testing equipment ensure each batch meets rigorous industry standards. The facility's design also incorporates sustainable practices, including solvent recovery systems and energy-efficient processing equipment.