No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

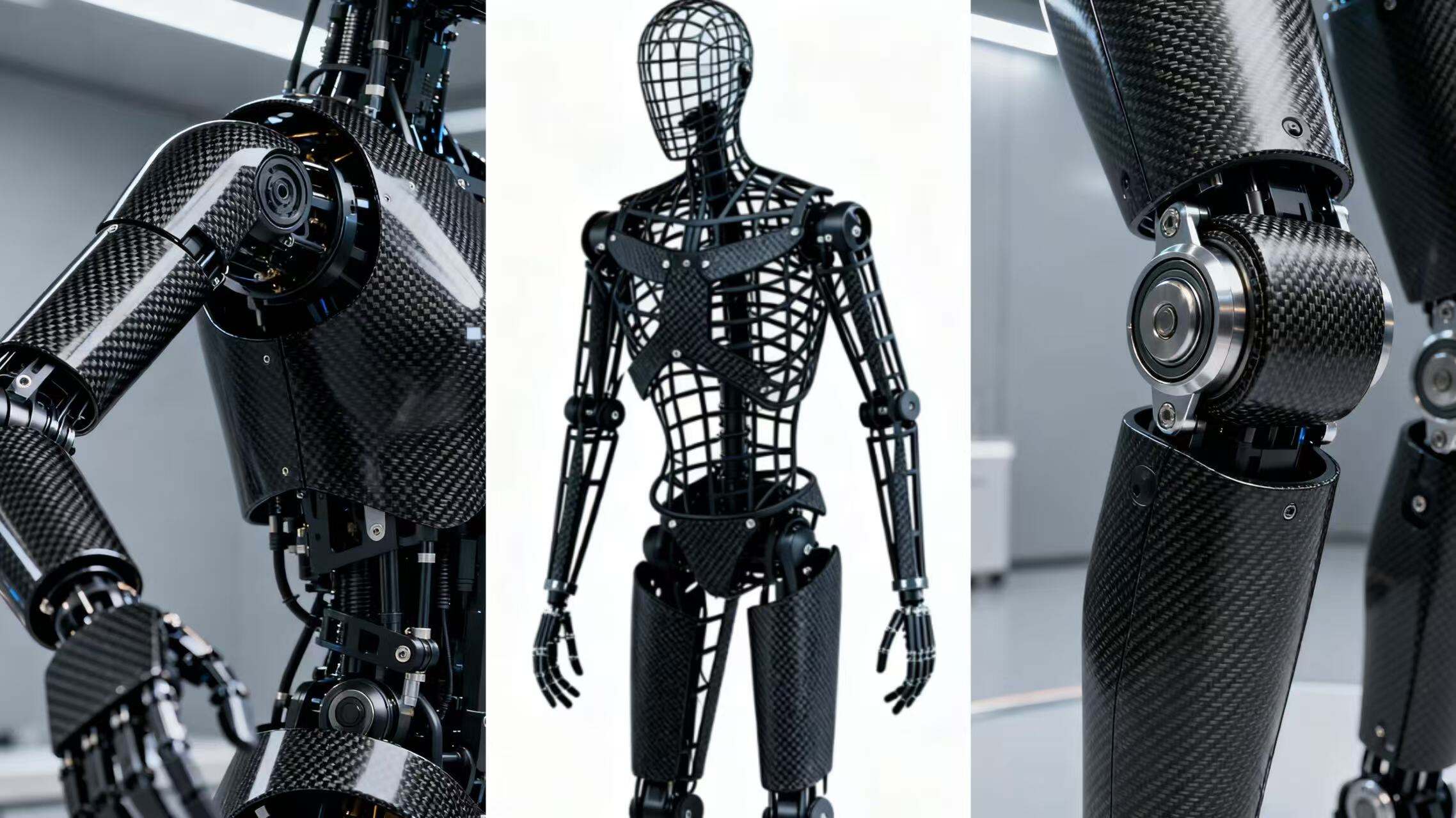

Tesla's Optimus navigates with agility, while UBTech's Walker arm performs deft operations. Behind these astonishing feats, a mysterious material 30% lighter than aluminium is redefining the limits of robotic motion.

Tesla's Optimus robot performs front flips, Figure AI's valuation surpasses $39.5 billion, and Zongqing Robotics' humanoid can walk at 7.2 kilometres per hour with straight knees... The humanoid robotics industry is accelerating towards explosive growth.

Goldman Sachs forecasts the humanoid robot market could reach $154 billion by 2035. To achieve this, robots must overcome a fundamental constraint: excessive self-weight severely impedes mobility performance.

The Lightweight Revolution: A Breakthrough Advancement Achieving 30% Weight Reduction

In the field of humanoid robotics, weight reduction is not merely a matter of 'slimming down', but rather a core technological breakthrough crucial to performance enhancement.

While traditional metallic materials possess sufficient strength, their high density makes them ill-suited to meet the urgent demand for robotic lightweighting. Take aluminium alloy as an example: with a density of 2.63–2.85 g/cm³, it is approximately two-thirds lighter than steel. Yet for humanoid robots pursuing extreme motion capabilities, this remains insufficient.

The advent of carbon fibre reinforced polymer (CFRP) has transformed this landscape. This composite material, featuring a resin matrix reinforced with carbon fibres, boasts a density of merely 1.5–2.0 g/cm³. It is approximately 30% lighter than aluminium alloys while exhibiting superior specific strength and specific modulus.

Research from domestic institutions indicates that robotic arms constructed from carbon fibre composites achieve a 30% reduction in overall mass compared to aluminium alloy counterparts. This enables robots to raise their arms with greater ease, execute finer movements, reduce motor load, and extend operational endurance.

Performance Enhancement: Comprehensive Advantages Surpassing Metal Materials

Carbon fibre composites are not only lighter than aluminium but also offer a range of comprehensive advantages over traditional metallic materials.

This material exhibits outstanding fatigue resistance and shock absorption, capable of withstanding the repeated impacts and vibrations inherent in robotic motion. For humanoid robots requiring prolonged operation, this characteristic is paramount.

Carbon fibre composites offer high design flexibility, allowing engineers to tailor fibre orientation, resin formulation, and layering methods according to the stress conditions of different components, achieving "precision performance customisation".

UBTECH's humanoid robotic arms utilise carbon fibre composites, not only reducing overall weight but also enhancing structural stability and motion precision. This material enables robots to perform more complex and intricate tasks.

In terms of dynamic performance, components made from carbon fibre composites feature a lower centre of gravity and reduced vibration. This directly translates to smoother motion execution and heightened control accuracy.

Application scenario: The primary load-bearing component of the robot's body

In humanoid robots, carbon fibre composites are primarily employed in three critical areas, each with distinct performance requirements.

(1) Manipulators and arms represent the most common application sites. These components must withstand substantial loads while maintaining high flexibility. The high specific strength and lightweight properties of carbon fibre composites render them an ideal choice for this purpose.

(2) The skeletal structure forms the robot's supporting framework. This section demands exceptional rigidity and strength to bear the entire body weight and withstand complex stresses from diverse movements. Carbon fibre composites deliver an outstanding stiffness-to-weight ratio while absorbing impact energy during motion.

(3)Joint components form the pivotal points for humanoid robot movement. These areas endure frequent rotation and load variations. Carbon fibre composites exhibit excellent wear resistance and fatigue resistance, significantly extending the service life of joint components.

Technology Convergence: The Synergistic Effects of Carbon Fibre

Carbon fibre composites are seldom employed in isolation; more often, they are combined with other high-performance materials to create synergistic effects, delivering a "1+12" advantage.

Carbon fibre-reinforced PEEK material exemplifies this principle. This composite integrates the strength of carbon fibre with PEEK's wear resistance and self-lubricating properties, making it particularly suited for manufacturing robotic joint gears and bearings. It reduces component wear while lowering energy consumption and noise levels.

When integrated with electronic skin technology, carbon fibre composites serve as the substrate layer, providing stable support for flexible sensors. This combination enables robots to possess both lightweight bodies and human-like skin sensitivity.

Carbon fibre composites can also be synergistically used with traditional metallic materials such as magnesium and aluminium alloys. By selecting the most suitable material combinations based on the stress characteristics of different components, overall performance optimisation is achieved.

Industrial Chain Layout: Opportunities and Challenges for Chinese Enterprises

China has established a relatively comprehensive industrial chain layout in the field of carbon fibre composites.

With the rapid development of the humanoid robotics industry, demand for carbon fibre composites is growing rapidly. Currently, the application of this material still faces challenges such as high costs and processing difficulties. However, with technological advances and scaled production, these issues are expected to be progressively resolved.

Walking, leaping, lifting, manipulating—each movement of humanoid robots represents an ultimate test of material performance. Carbon fibre composites, with their exceptional lightweighting effects and comprehensive performance advantages, are becoming indispensable for high-end humanoid robots.

Transitioning from laboratory research to commercial applications, the penetration rate of carbon fibre composites within the humanoid robotics sector is accelerating rapidly. This trend will not only propel a leap in robotic performance but also present fresh development opportunities for China's materials industry.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved