מס' 80 שדרה צ'אנגג'יאנג מינגז'ו, רחוב האוצ'נג, עיר ז'נגג'יאנג, מחוז ג'יאנגסו, סין +86-15995540423 [email protected] +86 15995540423

ויבר קרבון מוצרים , בזכות התכונות המרשימות שלהם של קלות משקל וחוזק גבוה, משמשים באופן רחב במגוון תרחישים, כגון רכיבי מטוסים באוויר וחלל, מבני גוף ברכב, וציוד מתקדם בספורט. כיצד הם הופכים מחומרים בסיסיים למוצרים מעשיים צעד אחר צעד? להלן הצגה מפורטת של נקודות המפתח בייצור לוחות פחמן, צינורות פחמן וחלקי פיברגלאס בצורות שונות.

הכנה של חומרים גולמיים

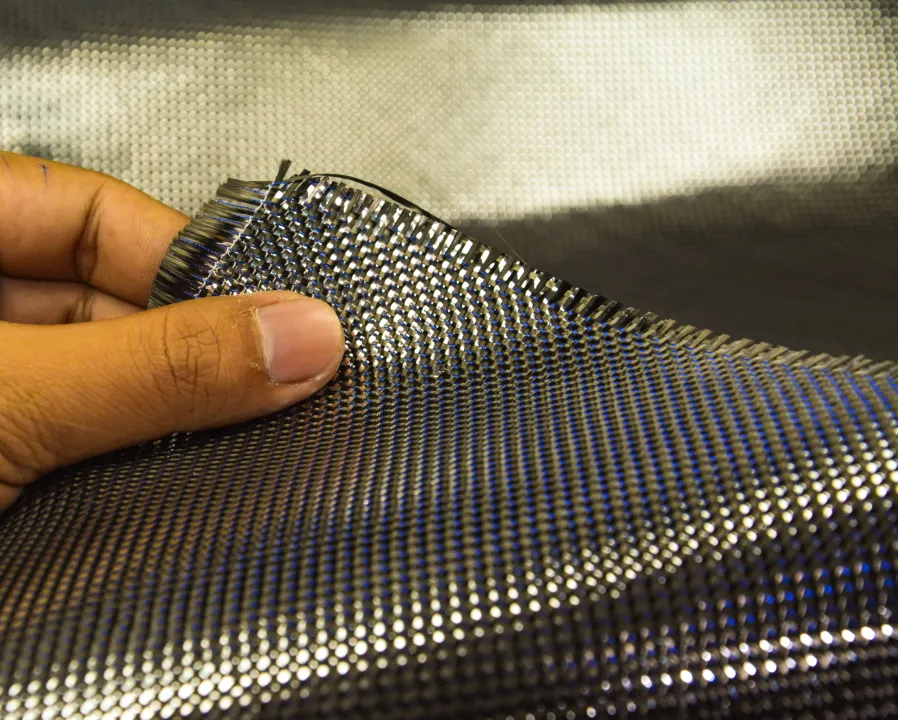

החומר הראשי של מוצרי פיברגלס כוללים יריעת פיברגלאס ומסות מילוי. תיילי פיברגלאס מיוצרים מסיבים אורגניים כגון פוליאקרילוניטריל שמומר בתהליך של פיחוך בטמפרטורות גבוהות. הקוטר שלהם הוא רק מספר מיקרון, דק הרבה יותר מקו שיער, אך חזק בהרבה מפלדה רגילה. תיילים אלו של פיברגלאס מעובדים בדרך כלל ליריעת פיברגלאס או לחריר פיברגלאס כדי לאפשר פעולות עיבוד נוספות.

חומר המטריצה הוא בעיקר רזינט אפוקסי וחומרים פולימריים אחרים, אשר ממלאים תפקיד חשוב, לא רק כדי לחבר את שיזופי סיבי הפחמן יחד, אלא גם כדי להעביר מתח, ולתת הגנה על שיזופי סיבי הפחמן, כדי שיתguardsו מפני סביבה חיצונית של לחות, חומרים קורוזיביים ושאר נזקים. לפני הייצור, ייבחרו שיזופי סיבי פחמן וחומרי מטריצה לפי דרישות המפרט בהתאם לדרישות הביצועים של מוצרים שונים, ויבוצעו בדיקות איכות מחמירות כדי להבטיח כי איכות החומרים הראשוניים עומדת בדרישות הייצור.

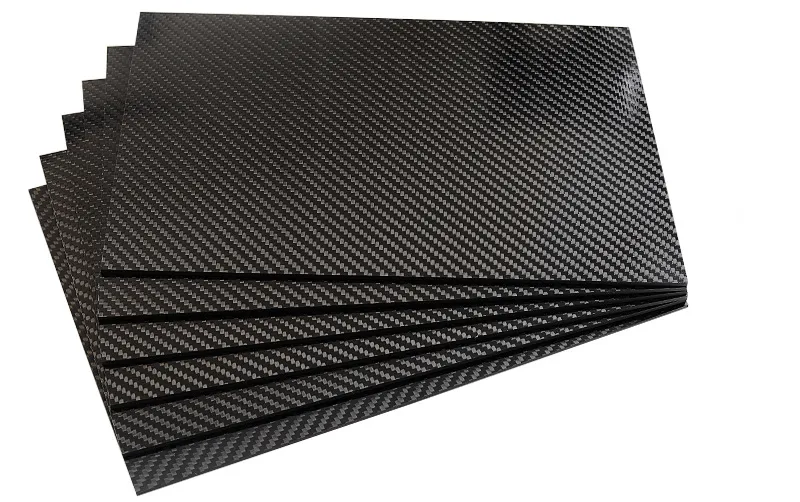

גיליון פחמן (עיצוב שכבות)

לוחות פחמן מיוצרים בעיקר באמצעות תהליך עיצוב השכבות, אשר משמש לעתים קרובות למוצרים כגון סקיים ומסגרות לשחמטני בדמינטון.

ראשית, בהתאם לדרישות העיצוב, יחתכו פריפרג סיבי פחמן , חומר מוקדם נמסס הוא חומר מקודח שנדבק מראש עם חומר הבסיס של בד פיברגלאס, וטעות החיתוך חייבת להישמר בתוך 0.1 מ"מ, כדי להבטיח דיוק ממדי של המוצרים הבאים.

לאחר מכן, חומרי המוקדם הנחתכים מתלפפים בכיוון ובסדר מסוימים. סידור חד-כיווני מעניק ללוח הפחמן חוזק גבוה בכיוון אחד, מה שמתאים לרכיבים מבניים שצריכים לעמוד בכוחות חד-כיווניים, בעוד שסידור צלבית מעניק ללוח הפחמן ביצועים טובים בכיוונים מרובים, מה שמתאים לרכיבים בתנאי כוח מורכבים.

אחר כך, מניחים את חומרי המוקדם הלופפים לתבניות ומיישמים לחץ של 5-10 MPa כדי שיחבו בצורה הדוקה לצורת התבניות, ואז מכניסים את התבניות למיכלי לחץ חם או לאפייה וחמים אותם בטמפרטורה של $120-180^{\circ} C$ במשך 2-4 שעות.

אחרי שהאיחוי הסתיים, מוציאים את לוח הפחמן מהתבנית, וביצוע עיבוד נוסף כגון סANDING וחיתוך כדי להביא אותו לתקן השימוש.

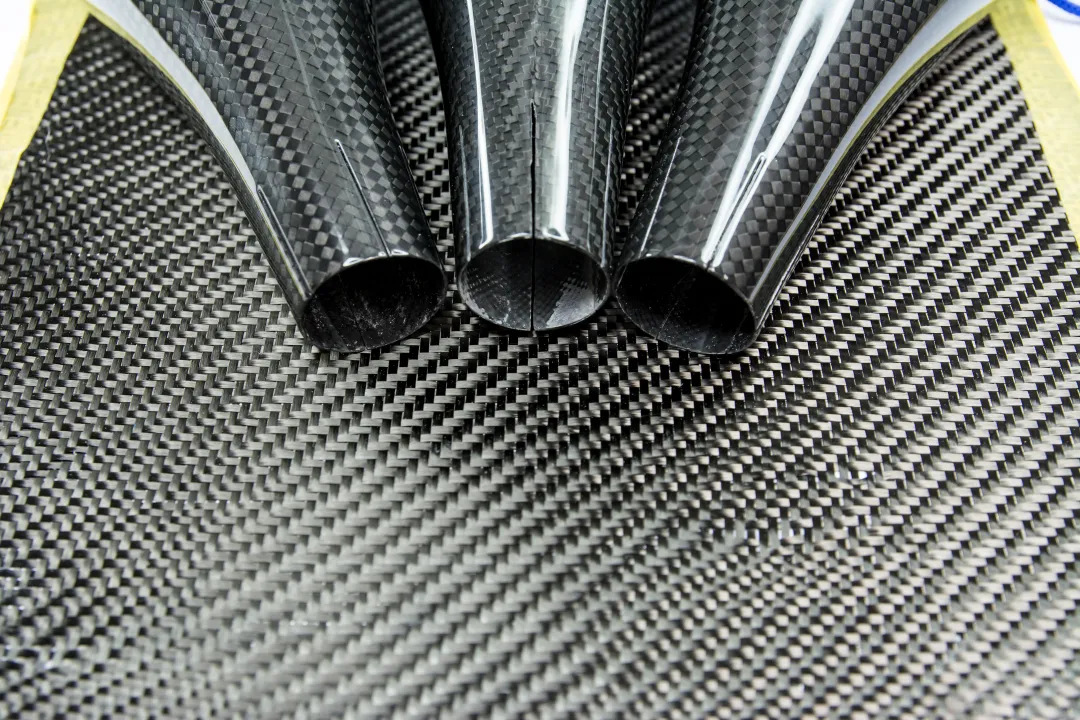

צינורות פחמן (لف ועיצוב)

צינורות פחמן מיוצרים בעיקר בתהליך לف ועיצוב, אשר בשימוש נפוץ למוצרים כגון מסגרות של רחפנים ומקלות גולף.

הפרמטרים של מכונת הلف נקבעים בהתאם לגודל ולדרישות הביצועים של צינור הפחמן, וביניהם זווית הلف היא אחת הפרמטרים המרכזיים. כאשר זווית הلف היא $\pm 45$ מעלות, התנגדות הפיתול של צינור הפחמן טובה יותר; כאשר זווית הلف היא 0 מעלות, העומס הצירי של צינור הפחמן יהיה גבוה יותר.

חוט הפיברגלאס מוכמס לחלוטין בחומר הבסיס באמצעות מכשיר ההכימוס, ולאחר שיוצר החוט המוכמס, הוא מלופף על גבי ליבה עם מתח של 5-15 נמ, והמתח חייב להישמר באופן אחיד במהלך תהליך הליפוף, כדי להבטיח איכות יציבה של צינור הפחמן.

לאחר הליפוף, צינור הפחמן עם המנדריל מוכנס לתנור ריפוי ומתיישר ב-100-150 מעלות צלזיוס למשך 1-3 שעות.

בסוף התהליך, מסירים את הליבה. שיטת ההסרה של הליבה תלויה בחומר ובצורה שלה, חלקן ניתנות להוצאה ישירות, בעוד שאחרות צריכות להיסלל ולהוסר, ולסיום מבצעים טrimming ופוליש לצינור הפיתול, כדי להגביל את שגיאת המידות בתוך 0.05 מ"מ.

חלקים מוצפנים (יציקה)

צורות מורכבות של חלקי פיברגלאס, תהליך ייצור נפוץ כמו ייצור חלקים לאוטומובילים, ציוד רפואי וכו', ברוב המקרים נעשה שימוש בתהליך זה.

ראשית כל, על פי הצורה של חלקים מעוצבים עיצוב וייצור של עובי דיוק גבוה, חריפות פני השטח של עובי צריך להיות נשלט מתחת Ra0.8, כי הדיוק של עובי משפיע ישירות על גודל ודאות הצורה של חלקים מעוצבים.

חתוך את הבד סיבים פחמן או מחצלת סיבים פחמן לגודל המתאים לצורת התבנית, צבע באופן שווה את חומר המטרקס על פני השטח שלו כדי להבטיח את העובי הוא עקבי, ולאחר מכן לשים אותו לתוך התבנית, ולאחר מכן להפעיל לחץ 10-20 MPa דרך המדח

לשים את התבנית במכשיר החימום, חימום וטיפול בטמפרטורה של 130-170 ° C במשך 3-6 שעות, תהליך הטיפול צריך לשלוט באופן קפדני בטמפרטורה וללחץ, כדי למנוע פגמים כגון בועות, סדקים ופגמים אחרים בחלקים המוענ

לאחר השלמת עיקור, מוצאים את החלקים המולטים מהתבניות ומעבדים אותם על ידי הסרת קצוות זעירים וסANDING של המשטחים כדי לעמוד בדרישות לשימוש.

טכנולוגיה נדחפת

1. הדפסה תלת-ממדית

טכנולוגiya זו יכולה לייצר ישירות צורות מורכבות של מוצרים מפחמן פיברגלוס, לצמצם בצורה משמעותית את מחזור פיתוח המוצר, וכן לאפשר התאמה אישית. עם זאת, כיום למוצרים מפחמן שמיוצרים באמצעות הדפסה תלת-ממדית עדיין יש פער מסוים בתכונות המכניות בהשוואה למוצרים המיוצרים בשיטת הייצור המסורתית, והעלות שלהם גבוהה יחסית, ולכן היבטים אלו צריכים עוד שיפור.

2. טכנולוגיית RTM

כלומר, טכנולוגיית עיבוד פליזת רזין, היא שיטה בה חומר הגברה מפוצץ לחריץ, ואז מתיזים רזין לתוך החריץ, כך שהרזין חודר את חומר ההגברה ומשת hardened. לטכנולוגיה זו יש יתרונות של יעילות גבוהה בתהליך הייצור, איכות מוצר יציבה, זיהום סביבתי נמוך וכו'. היא מתאימה במיוחד לייצור המוני של מוצרים מפיברגלאס בצורות מורכבות.

בדיקת איכות: הבטחת איכות של כל מוצר

אחרי שיוצרו המוצרים מפיברגלאס, עליהם לעבור בדיקות איכות קפדניות לפני הכניסה לשוק. פריטי הבדיקה כוללים דיוק ממדי, איכות מראה ותכונות מכניות.

בדיקת דיוק ממדי יכולה להשתמש בקלהים, מדידות ממוחשבות ועוד כלים; למוצרים הדורשים דיוק גבוה, ישתמשו גם במכונת מדידה קואורדינטית (CMM); בדיקת איכות החיצונית מתמקדת בעיקר בבדיקה האם יש בועות, סדקים, שקעים ופגמים אחרים על פני השטח של המוצר, ובדרך כלל משמש שילוב של בדיקה ויזואלית עם שימוש במגדלת; בדיקות תכונות מכניות דורשות שימוש במכונות לבדיקת מתיחה, מכונות להבאת מכות וציוד מקצועי אחר, כדי לבדוק את חוזק, קשיחות, עמידות ותכונות אחרות של המוצר, כדי להבטיח שהוא עומד בדרישות הכוח בשימוש בפועל. בדיקות ביצועים מכניים דורשות שימוש במכונות מתיחה וציוד מקצועי אחר כדי לבדוק את עוצמת המוצר, הקשיחות, העמידות ועוד מדדים, כדי להבטיח שהמוצר מסוגל לעמוד בדרישות הכוח בשימוש בפועל. רק מוצרים שעברו בהצלחה את כל פרוייקטי הבדיקה יקבלו רשות להיכנס לשוק.

בדיקת דיוק ממדי יכולה להשתמש במדידות, מקרנים וכלים אחרים, ובדרישות גבוהות של דיוק המוצר, ישתמשו גם ב-CMM; בדיקת איכות החיצונית היא בעיקר כדי לבדוק האם יש בפנימית המוצר בועות, סדקים, שקעים ופגמים אחרים, בדרך כלל באמצעות שילוב של בדיקה ויזואלית ובדיקת משקפת מגדלת; בדיקות תכונות מכניות דורשות שימוש במכונות לבדיקת מתיחה, מכונות לבדיקת מכה וכלי מדידה מקצועיים אחרים, כדי לבדוק את חוזק המוצר, קשיחות, עמידות ומאפיינים אחרים כדי להבטיח שהמוצר יכול לעמוד בדרישות הכוח בשימוש בפועל. בדיקות ביצועים מכניים דורשות שימוש במכונות מתיחה וכלי ציוד מקצועיים אחרים כדי לבדוק את עוצמת המוצר, הקשיחות, העמידות ומאפיינים אחרים כדי להבטיח שהמוצר יכול לעמוד בדרישות הכוח בשימוש בפועל. רק מוצרים שעברו בהצלחה את כל פרויקטי הבדיקה יכולים להכנס לשוק.

כל הזכויות שמורות © 2026 ז'נגג'יאג'נג ויינואה קומפוזיטס ש.ר.ל.